Car tail gas backflash device

A technology of automobile exhaust and body measurements, which is applied in the direction of exhaust devices, noise reduction devices, engine components, etc., can solve the problems of harmful engines, environmental pollution, and harm to human health, and achieve the effect of environmental protection and fuel saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

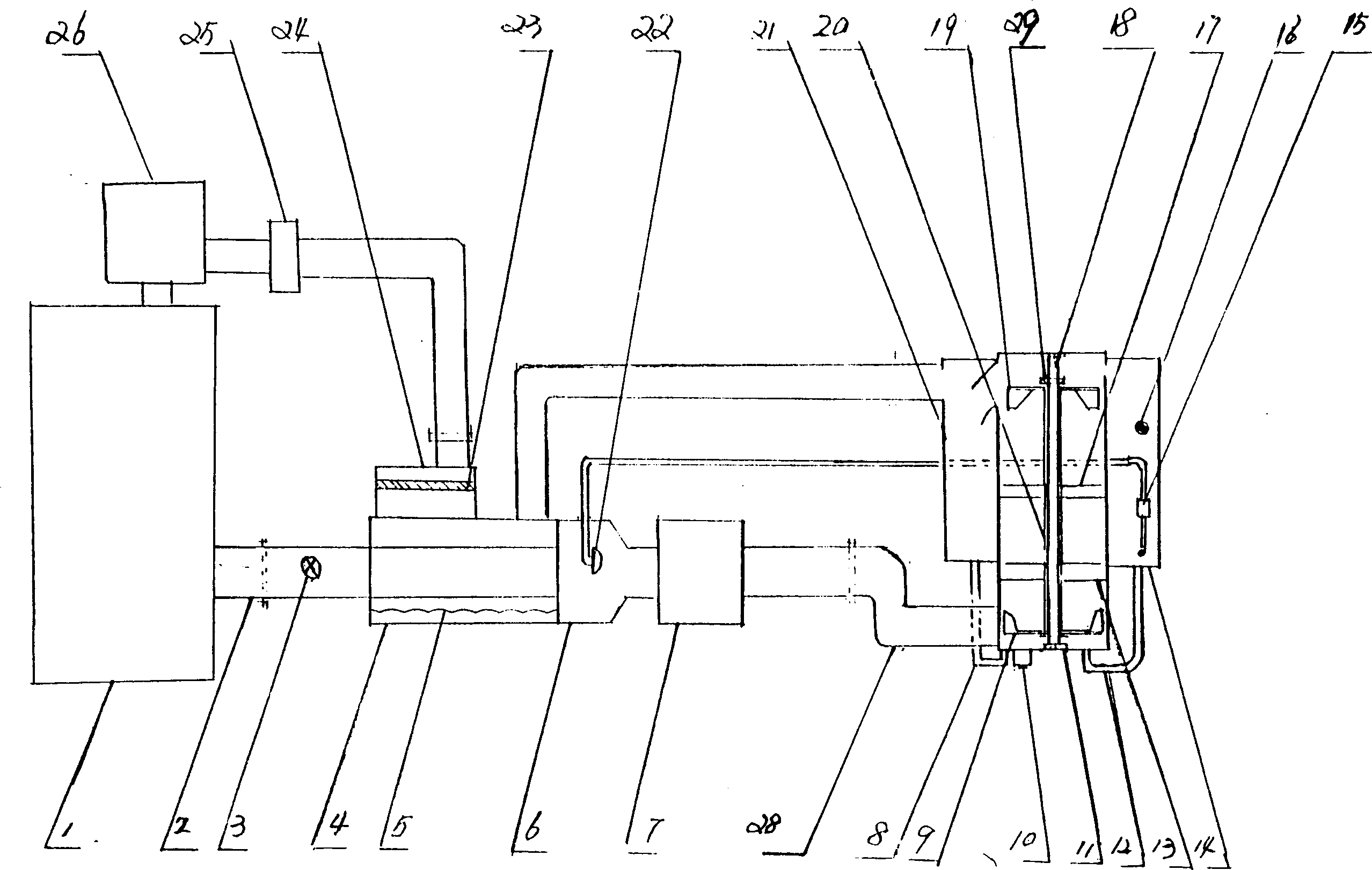

[0024] As shown in the figure, it is equipped with a safety vent valve 3 at the front end, and the central exhaust pipe 2 is sealed at both ends. The expansion cracking chamber 4 is connected to the spray box 6, and the filter box 24 is connected to the turbocharger with the upper part of the expansion cracking chamber. 25. The heat dissipation cooling box 7 and the tail gas reaction tank 11 are composed of an electric pump 15 and an inductor 16 on the auxiliary tank 14 of the reaction tank.

[0025] A cavity is formed between the central exhaust pipe 2 and the sleeve pipe 4 of the expansion cracking chamber, and a corrugated insert 5 is installed in the cavity and welded with the central exhaust pipe 2 . One end of the spray box 6 is sealed and welded with one end of the expansion cracking chamber 4, and the central exhaust pipe 2 is used to disconnect the cavity to form a nozzle 22, which is connected to the upper part of the expansion cracking chamber. The filter box 24 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com