Flame-retarding type active carbon and its preparation method

An activated carbon, flame retardant technology, applied in the field of new activated carbon and its preparation, can solve the problems of not well solved, fire danger, affecting use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

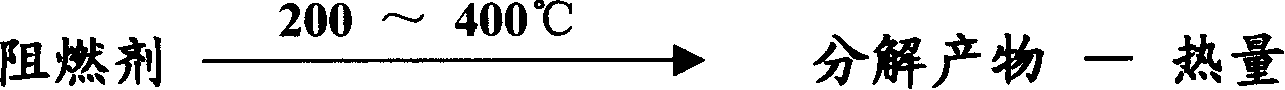

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 90 parts of coal-based cylindrical granular activated carbon (weight percentage, the same below), using 10 parts of water-soluble ammonium polyphosphate flame retardant, adding 62 parts of water to the flame retardant to form an ammonium polyphosphate aqueous solution, impregnating the granular activated carbon under constant stirring Then bake it at 150°C for 2 hours to make flame-retardant granular activated carbon, and its properties are shown in Table 1.

Embodiment 2

[0020] 95 parts of fibrous activated carbon (percentage by weight, the same below), using 5 parts of tris (β-chloroethyl) phosphate flame retardant, evenly sprayed on the fibrous activated carbon, and then baked at 120 ° C for 2 hours. into flame-retardant fibrous activated carbon, and its properties are shown in Table 1.

Embodiment 3

[0022] 80 parts of coal-based activated carbon powder (weight percentage, the same below), 10 parts of bentonite, and 10 parts of particulate aluminum hydroxide flame retardant were put into a ball mill for 5 hours, passed through a 180-mesh vibrating screen, and mixed with about 30 parts of water to make a mud cake , and then kneaded, formed by extrusion through a special metal mold to make a cuboid with a size of 50×50×100, with a complete honeycomb structure, and then baked at 200°C for 2 hours to make a flame-retardant Type honeycomb activated carbon, its properties are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com