Motorised valve

A technology of electric valve and valve body, which is applied in the direction of lifting valve, valve device, valve details, etc. It can solve the problems that are not easy, not particularly difficult, difficult, etc., and achieve the effects of stable installation state, easy manufacturing, and simplified composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

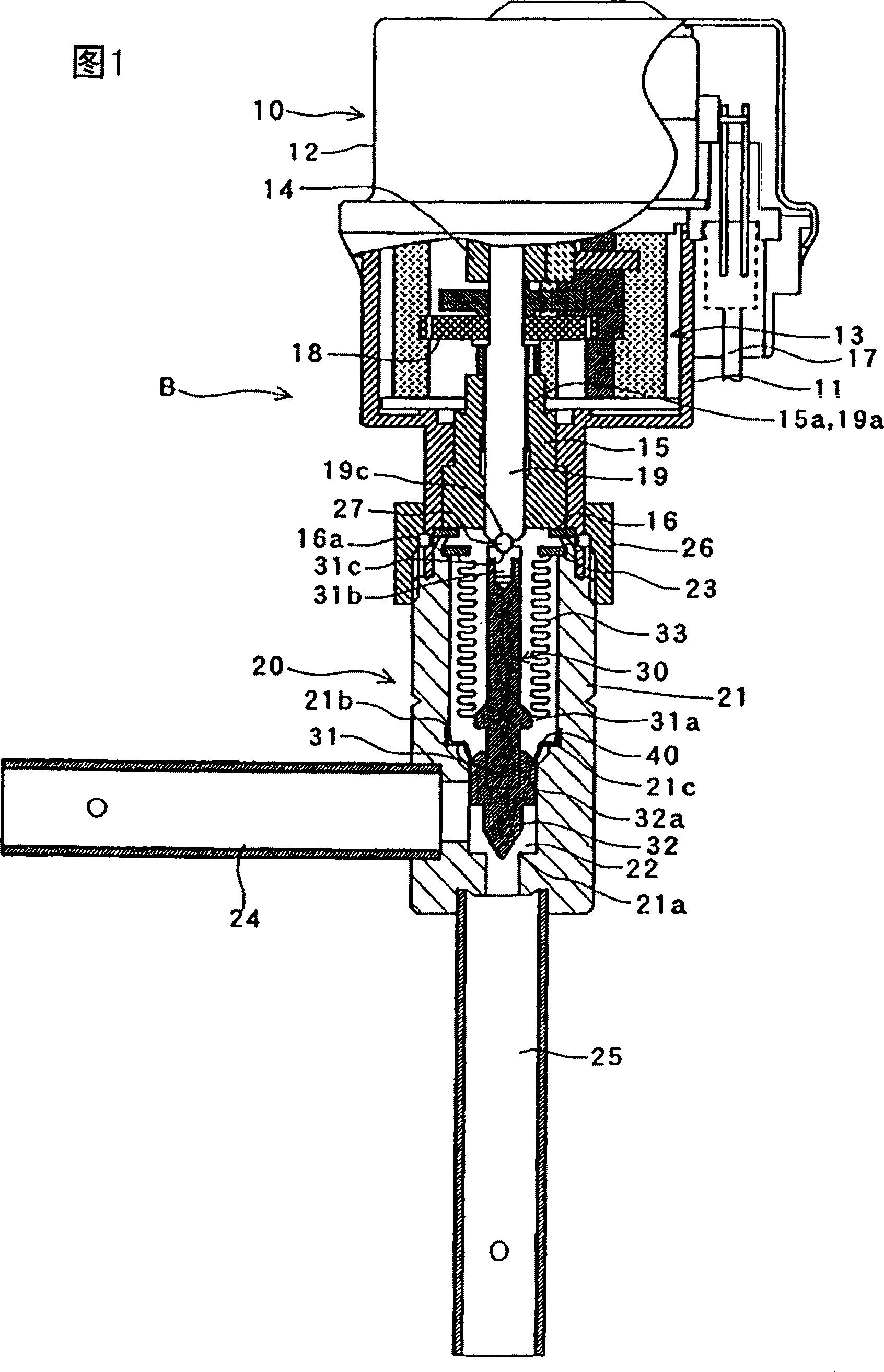

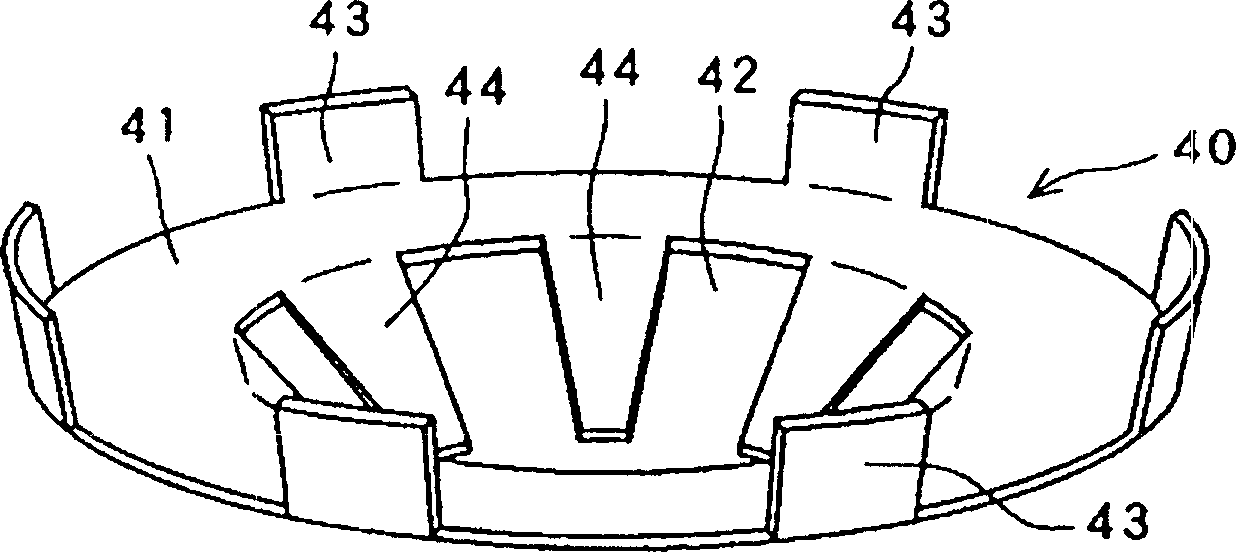

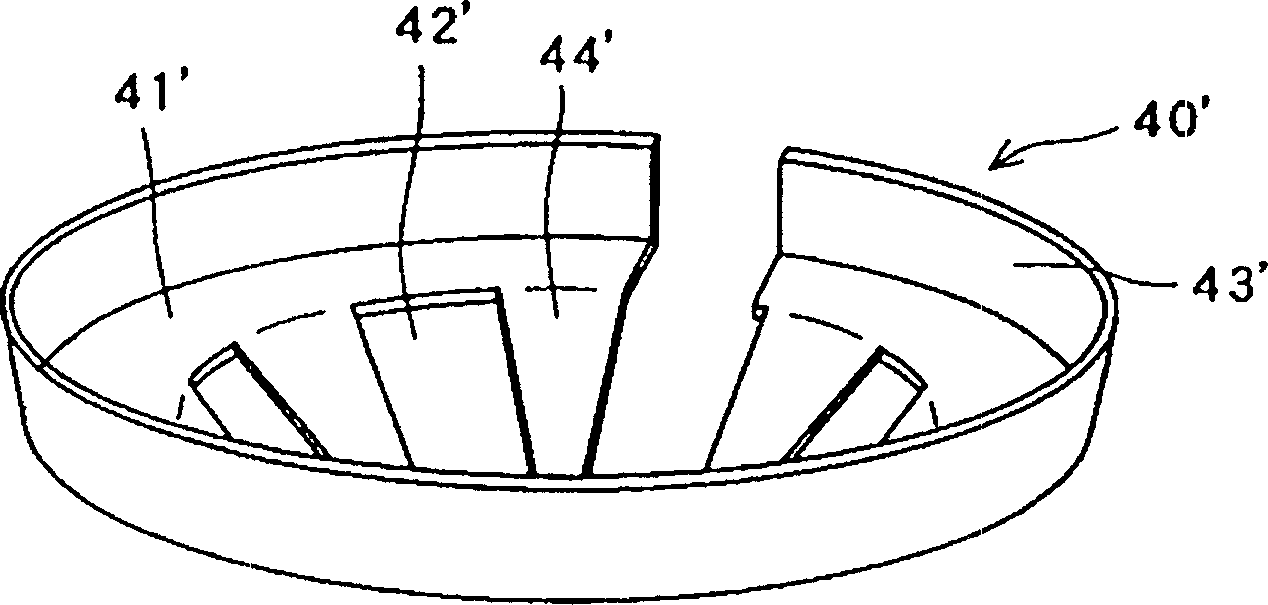

[0036] Embodiment 1 of the electric valve of the present invention will be described below with reference to the accompanying drawings. Fig. 1 is a schematic partial longitudinal sectional view thereof. figure 2 is a perspective view of its main part (stopper). image 3 is a perspective view of another form of its main part (stopper). Figure 4 It is an explanatory diagram of the function of the main part (stopper).

[0037] The electric valve B is composed of a drive unit 10 and a valve body unit 20 .

[0038] First, the drive unit 10 will be described. The drive unit 10 is constituted by a stepping motor (no symbol) mounted on a case body 11 , a motor case 12 covering the stepping motor, and the like. The stepper motor is provided with leads 17 . A reduction mechanism 13 composed of various gears is disposed on the lower portion of the housing body 11 .

[0039] The reduction mechanism 13 is driven by a stepping motor, and is transmitted to an output rotary shaft 19 th...

Embodiment 2

[0057] Next, Embodiment 2 of the present invention will be described. Figure 5 It is a longitudinal sectional view of its main part, and on the same constituent parts as the above-mentioned embodiment 1, in Figure 5 The winning mark is the same as that in Figure 1~ Figure 4 The referenced symbols are the same symbols, and therefore, description thereof will be omitted.

[0058] In Embodiment 2, when the valve body 30 moves upward and protrudes above the valve body 21, the contact portion 32b of the valve 32 that is in contact with the stopper 40 is not provided with the engaging step 32a as in Embodiment 1, but is in contact with the stopper 40. A sloped flat face with the same other faces. According to the structure of the second embodiment, the structure of the valve 32 is simple and can be processed easily. In addition, in Embodiment 2, the lower edge of the portion 44 of the stopper 40 that contacts the valve body (the contact surface to the contact portion 32b of th...

Embodiment 3

[0061] Below, with regard to embodiment 3 of the present invention, illustrate, Image 6 It is the longitudinal sectional view of its main part. Figure 7 is to further enlarge Image 6 Sectional view of main parts. Figure 8 is an enlarged sectional view of the stopper 50 . In addition, in Embodiment 3, in terms of the same constituents as in Embodiment 1 above, in Figure 6 ~ Figure 7 The winning mark is the same as that in Figure 1~ Figure 4 The referenced symbols are the same symbols, and therefore, description thereof will be omitted.

[0062] On a portion of the inner surface of the valve body 21, an attachment recess C for a stopper 50 to be described later is formed. The mounting recess C is composed of an upper fitting step 21b, a back support portion 21d and a lower fitting step 21e below the back support portion 21d. The back support portion 21d is continuous with the upper fitting step 21b, and has a uniform inner diameter substantially parallel to the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com