Process for manufacturing integrated circuit on a substrate

A manufacturing method, integrated circuit technology, applied in the direction of circuit, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problem that the transistor channel cannot be effectively shortened

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

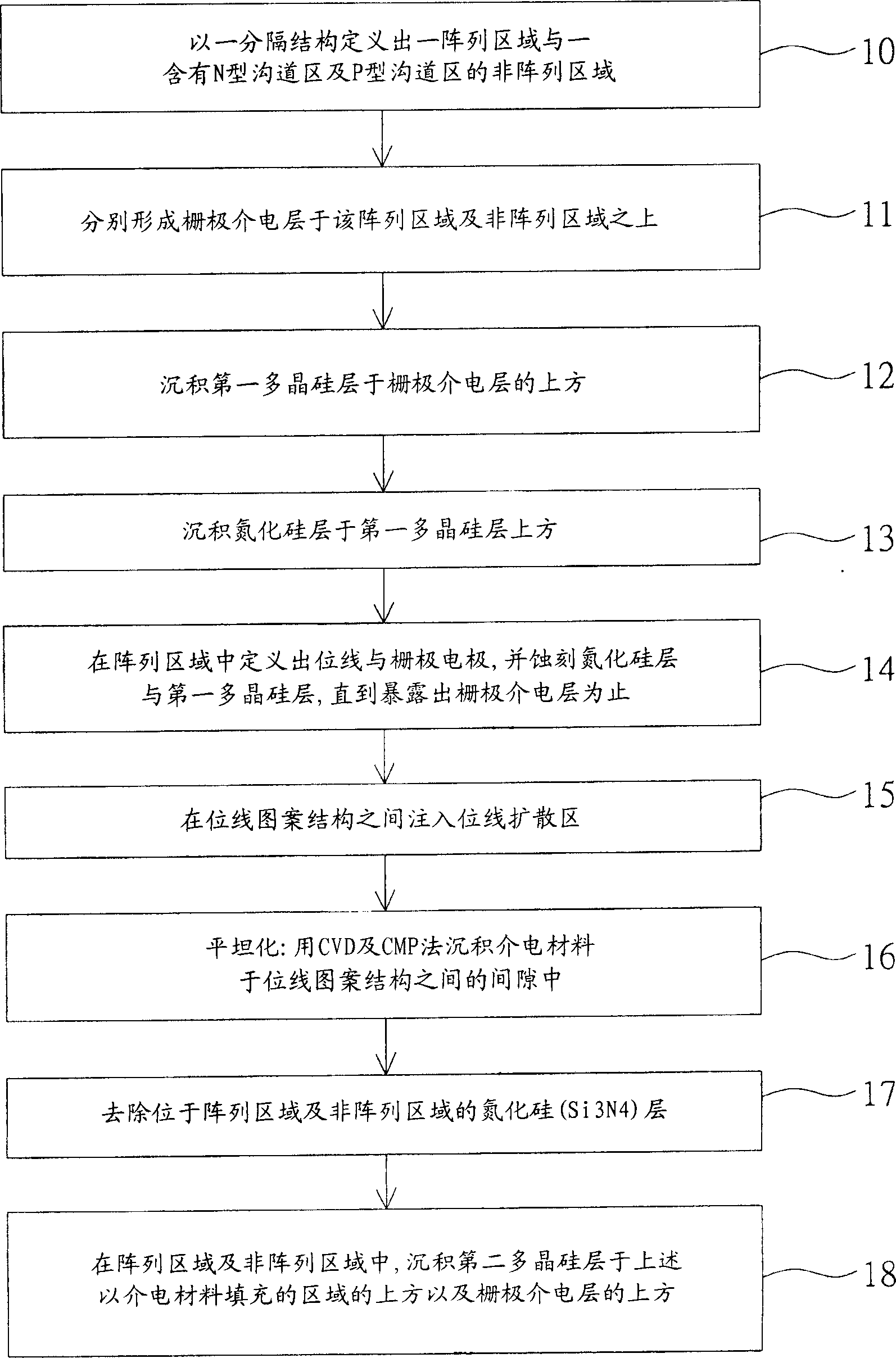

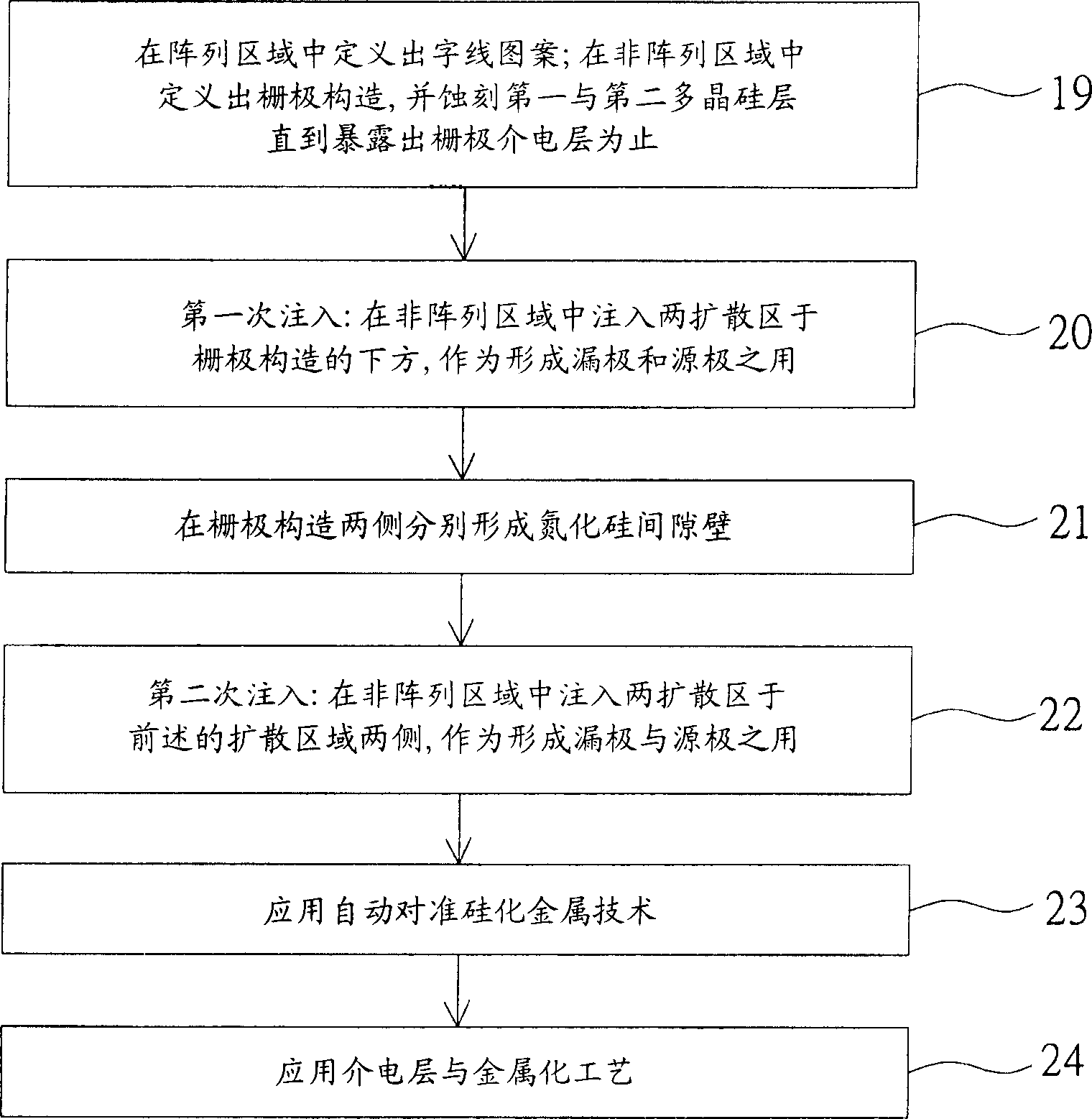

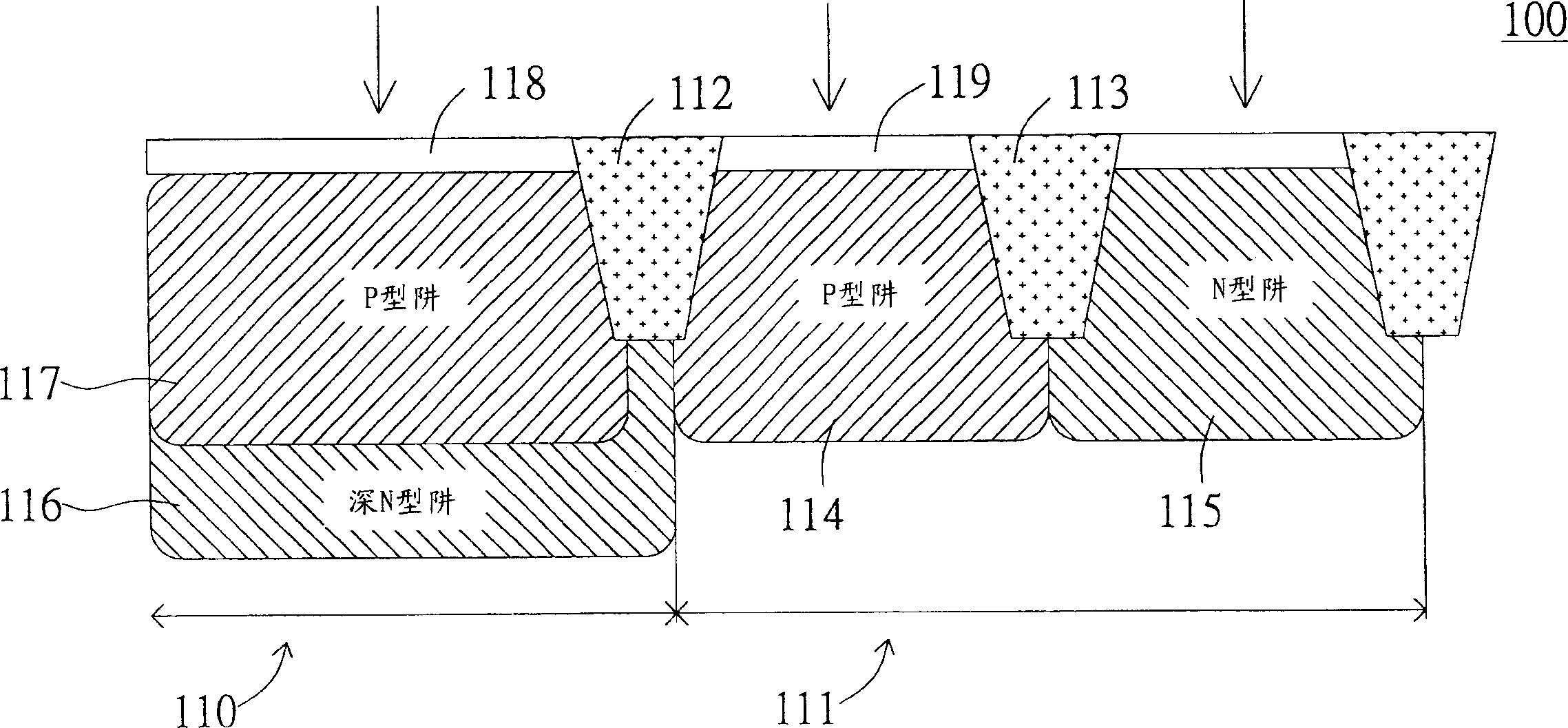

[0040] The manufacturing method disclosed in the present invention will be described in detail as follows with examples and accompanying drawings. Figure 1A-1B is a flowchart of a manufacturing method according to an embodiment of the present invention. Figure 2-10 is according to Figure 1A-1B The block diagram of the hybrid integrated circuit with embedded mask memory shown in the steps. and Figure 11 is the application Figure 2-10 Block diagram of embedded non-volatile memory with SONOS memory for process technology.

[0041] Please refer to Figure 1A-1B , each step is arranged in numerical order from step block 10 to step block 24 to illustrate the manufacturing method of the present invention. First, as described in step block 10 , the substrate is separated by a dielectric region 112 to define an array region 110 and a non-array region 111 . like figure 2 As shown, the dielectric region 112 is formed on the substrate by filling a trench with oxide or other diel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com