Thermoplastic fluorescent pigment

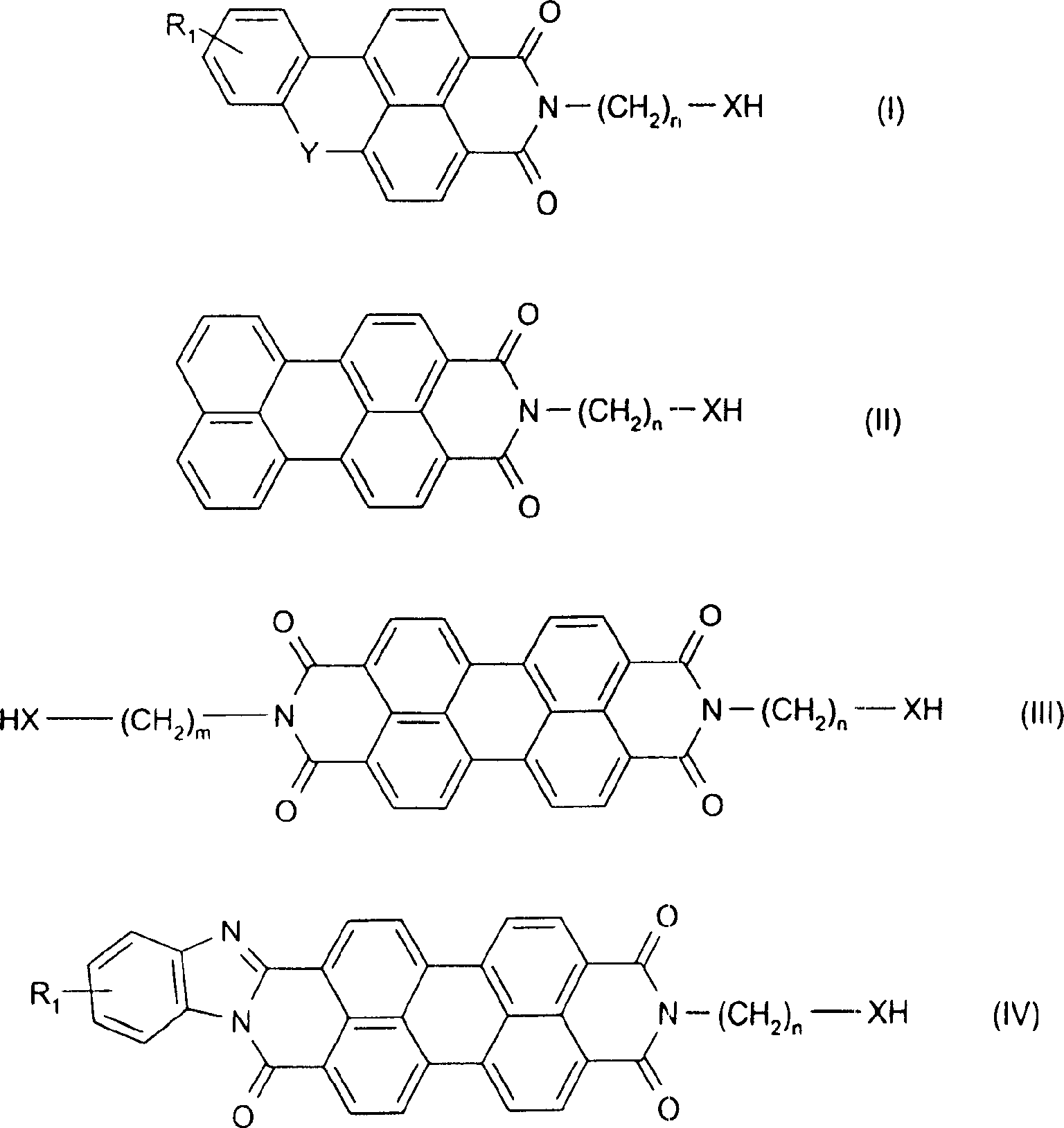

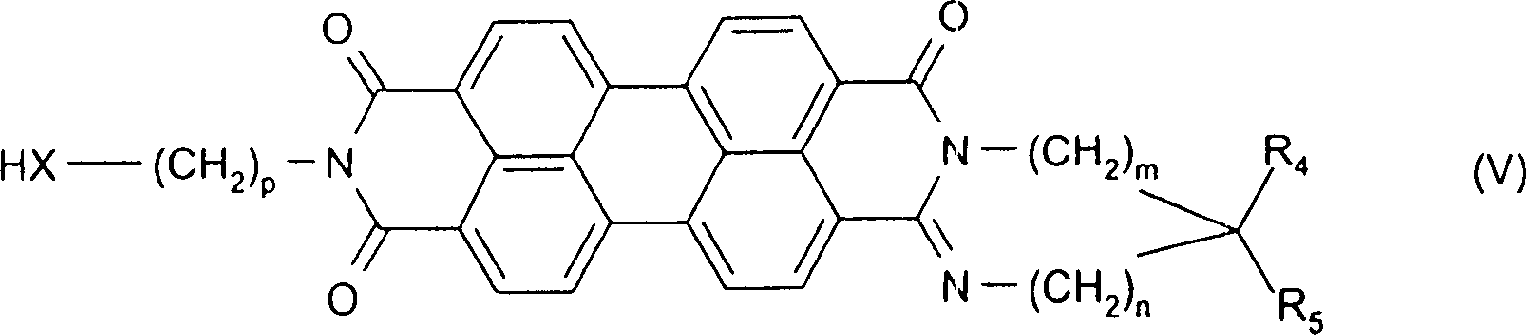

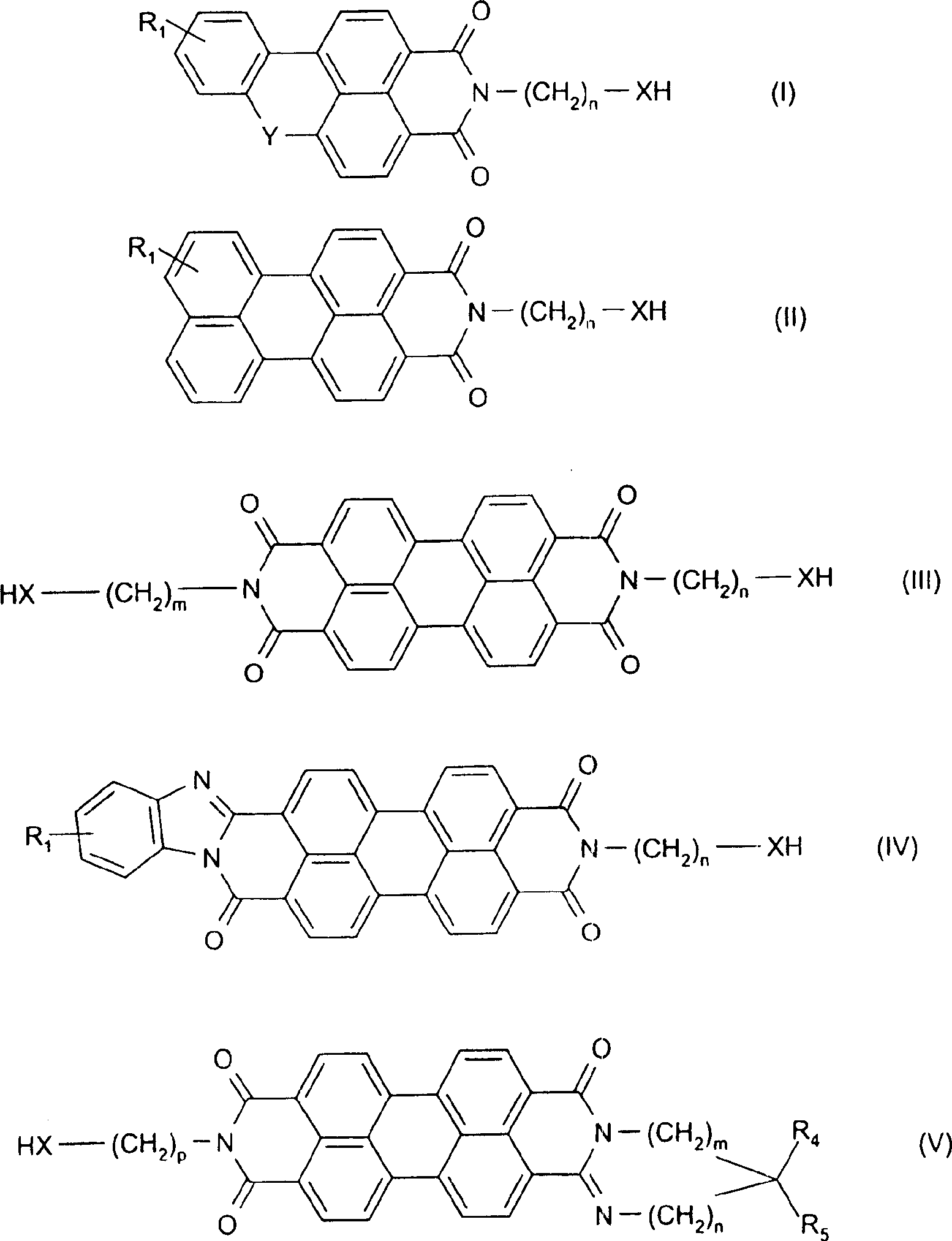

A fluorescent pigment and thermoplastic technology, applied in luminescent materials, anthracene dyes, powder coatings, etc., can solve the problems of limited solubility and light color of fluorescent dyes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Into a four-neck flask equipped with a stirrer, a reflux condenser and a thermocouple were charged 200 parts of isophorone diisocyanate, 38.5 parts of p-toluenesulfonamide and 10 parts of triethylamine. While stirring the mixture, its temperature was raised to 70°C, and the reaction was carried out for 1.5 hours to obtain a liquid prepolymer. The prepolymer thus obtained was mixed with 7.2 parts of the fluorescent dye Solvent Yellow 160 at a temperature of 50-60°C.

[0049] Separately, an aqueous protective glue solution was prepared by dissolving 6.0 parts of an acrylamide / sodium acrylate copolymer (CYNAMER 370 produced by Cytec Industries) in 2000 parts of water. After raising the temperature of the aqueous solution to 70° C., 10 parts of triethylamine was added, and the mixture was stirred at 7000 rpm with a high-speed stirrer. When the protective colloid solution was stirred, 120 parts of isophorone diamine was added, and then the liquid prepolymer was slowly added...

Embodiment 2

[0056] Into a four-neck flask equipped with a stirrer, a reflux condenser and a thermocouple were charged 200 parts of isophorone diisocyanate, 38.5 parts of p-toluenesulfonamide and 10 parts of triethylamine. While stirring the mixture, its temperature was raised to 70°C, and the reaction was carried out for 1.5 hours to obtain a liquid prepolymer. The reaction solution was treated with 5.0 parts of oxalic acid to neutralize excess triethylamine. The prepolymer thus obtained was mixed with 7.2 parts of the fluorescent dye Basic Yellow 40 at a temperature of 50-60°C.

[0057] Separately, an aqueous protective glue solution was prepared by dissolving 6.0 parts of an acrylamide / sodium acrylate copolymer (CYNAMERP-21 produced by Cytec Industries) in 2000 parts of water. After raising the temperature of the aqueous solution to 70° C., the mixture was stirred at 7000 rpm with a high-speed stirrer. While the aqueous protective colloid solution was being stirred, 120 parts of isoph...

Embodiment 3

[0062] 150 parts of isophorone diisocyanate, 50 parts of 2,4-toluene diisocyanate, 38.5 parts of p-toluenesulfonamide and 10 parts of triethylamine. While stirring the mixture, its temperature was raised to 70°C, and the reaction was carried out for 1.5 hours to obtain a liquid prepolymer. The prepolymer thus obtained was mixed with 0.80 parts of Basonyl red 485 and 4.3 parts of Basonyl red 560 at a temperature of 50-60°C.

[0063] Separately, prepare 2000 parts of protective colloid aqueous solution in water with the operation of Example 1. After raising the temperature of the aqueous solution to 70° C., 10 parts of triethylamine was added, and the mixture was stirred at 7000 rpm with a high-speed stirrer. While the protective colloid solution was being stirred, a mixture of 52.8 parts of isophoronediamine and 85.6 parts of pentaerythritol was added, and then the liquid prepolymer was slowly added to the protective colloid solution within 0.5 hours to obtain a bright pink s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com