Trimming apparatus and method for fuel cell membrane/electrode coupling and transporting apparatus

A fuel cell membrane and electrode assembly technology, which is applied to fuel cell grouping, fuel cell parts, fuel cells, etc., to achieve the effect of improving productivity, smooth and fast suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

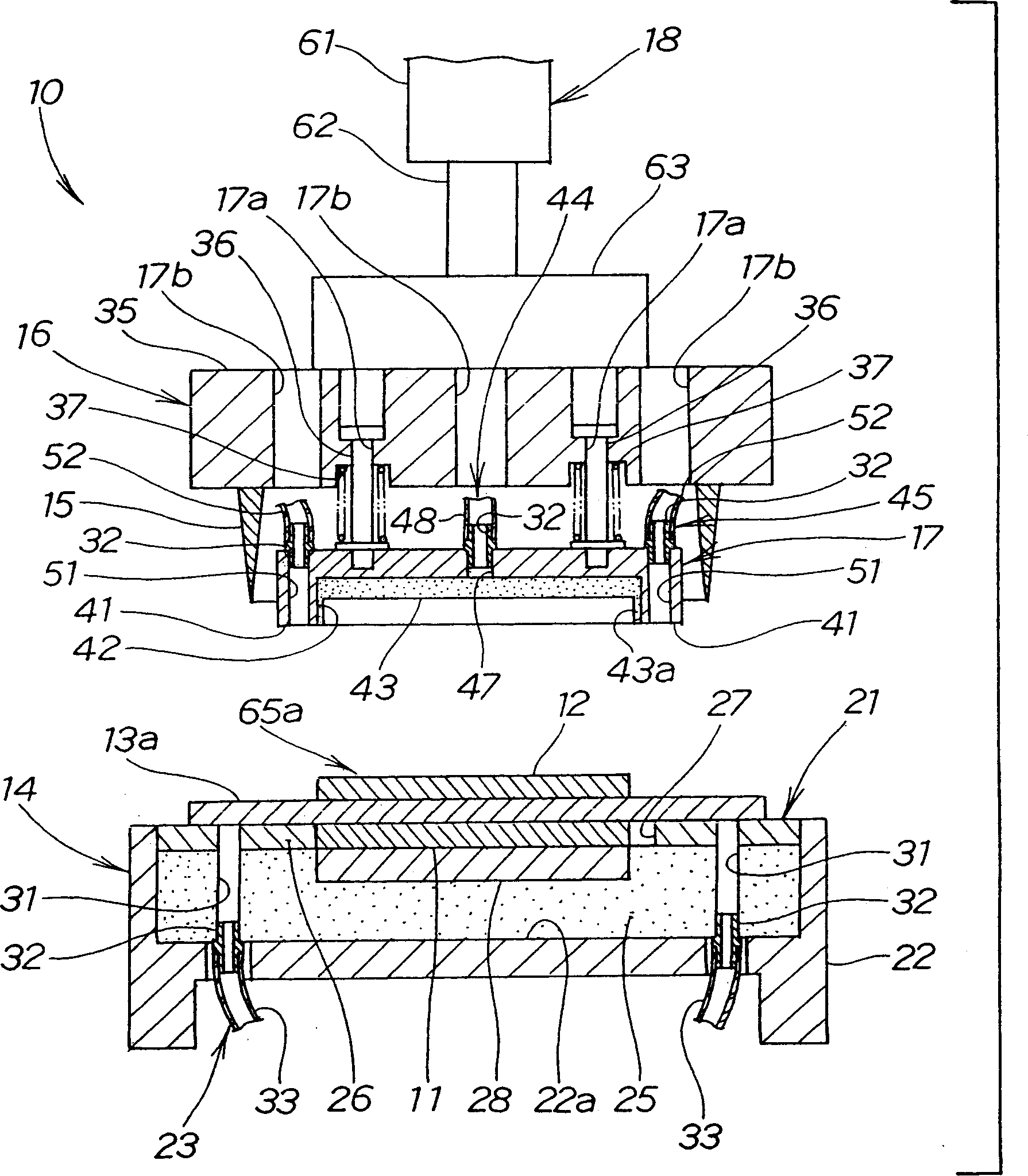

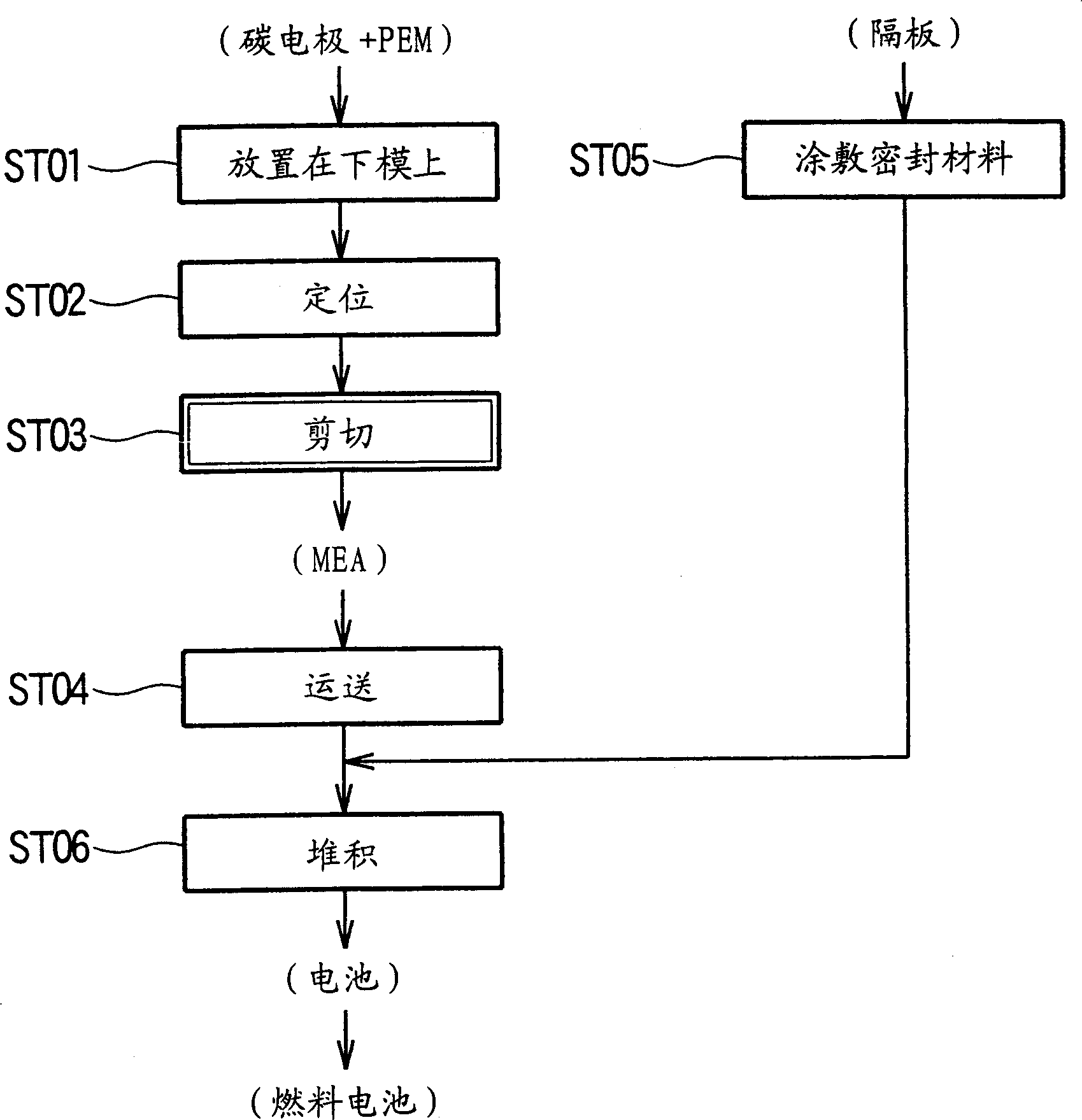

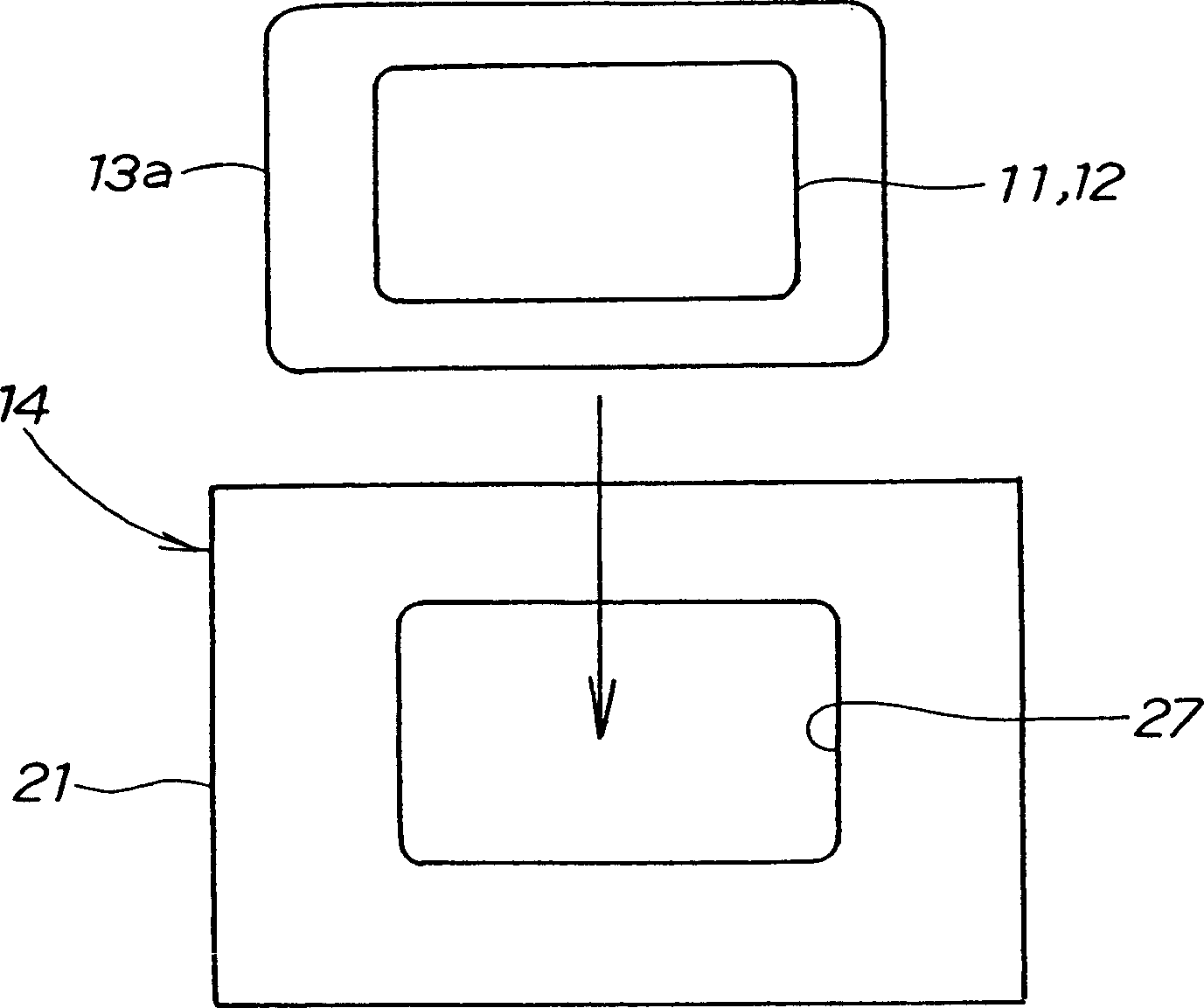

[0065] Such as figure 1 As shown in , the membrane / electrode assembly punching device 10 (hereinafter referred to as "MEA punching device 10") constituting the punching station is composed of the following components, namely: a lower die 14, on which a polymer electrolyte membrane 13a is placed (hereinafter written as "PEM13a"; as such, the PEM before punching is written as PEM13a to distinguish it from PEM13 after punching which will be discussed further later), the polymer electrolyte membrane 13a has a pressurized Carbon electrodes 11, 12 made of carbon paper fixed to its two sides; upper die 16 with a punching blade 15 for cutting off the edge of the PEM 13a (i.e. punching the PEM 13a); suction / clamping device 17, It serves as a pressing piece connected with the upper die 16 for sucking and clamping the carbon electrode 12 and the PEM 13a; and a cylinder device 18 for lowering the upper die 16 .

[0066] This lower die 14 is made up of following parts, namely: table part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com