Magnesium alloy laser-TIG welding process

A welding method and magnesium alloy technology, applied in the field of material engineering, can solve the problems of high energy consumption and low production efficiency, and achieve the effects of high joint quality, high production efficiency and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

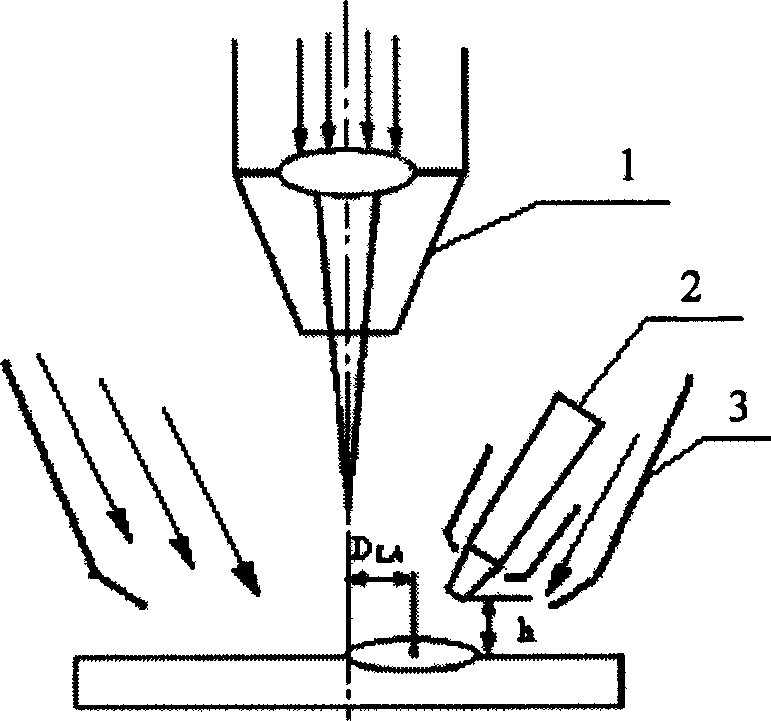

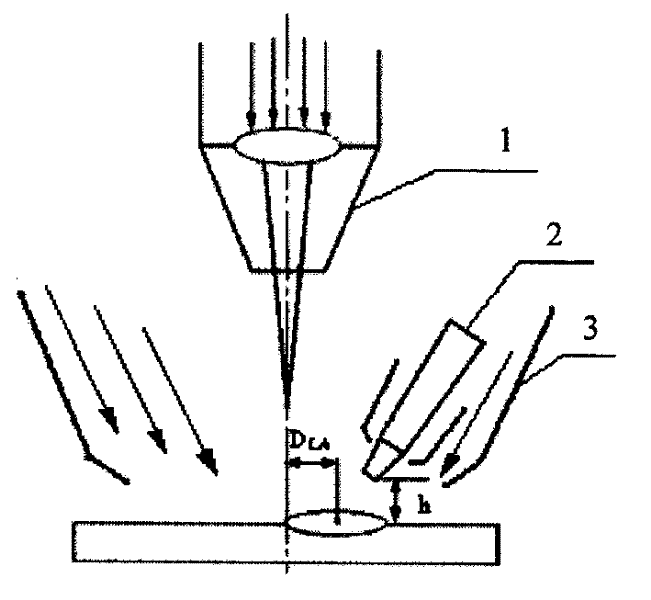

[0009] This implementation mode refers to figure 1 As shown, 1 is the laser beam, 2 is the TIG welding torch, and 3 is the shielding gas cover, where the distance between the impact point of the laser beam 1 and the center of the welding pool of the TIG welding torch 2 is D LA 2.5mm; the distance from the tip of the welding torch 2 tungsten electrode to the workpiece is 1.2mm. Then set the shielding gas flow, TIG welding current and laser power according to the plate thickness. When welding the deformed magnesium alloy AZ31B with a plate thickness of 2.5mm, the TIG arc welding current is selected as 90A, the laser power is 500W, and the welding speed can reach more than 1000mm / min. In this way, on the one hand, the shape of the weld seam is significantly improved, on the other hand, the welding quality is good and the efficiency is high, so that the energy can be used most effectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com