Method for preparing porous filter membrane of polytetrafluoroethylene electret

A technology of polytetrafluoroethylene and filter membrane, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to achieve the effect of novel concept and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

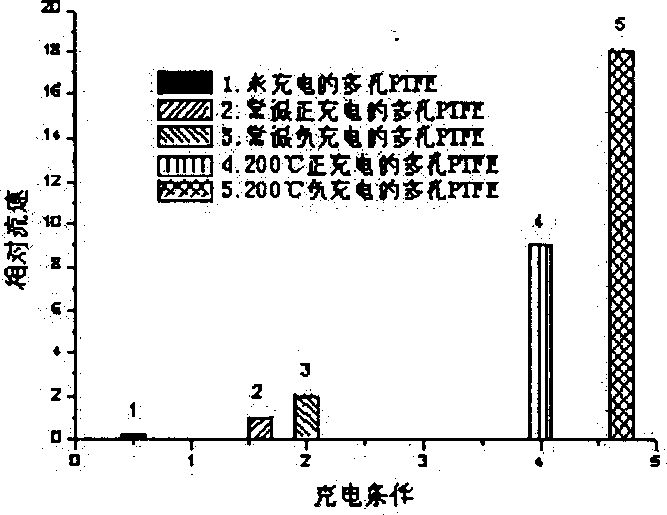

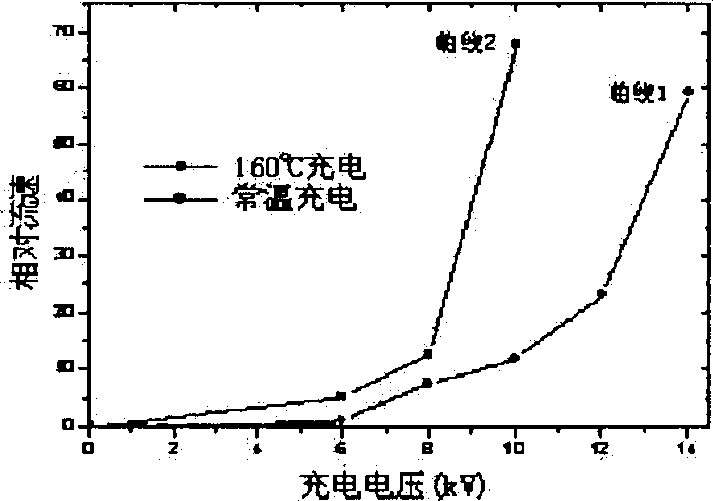

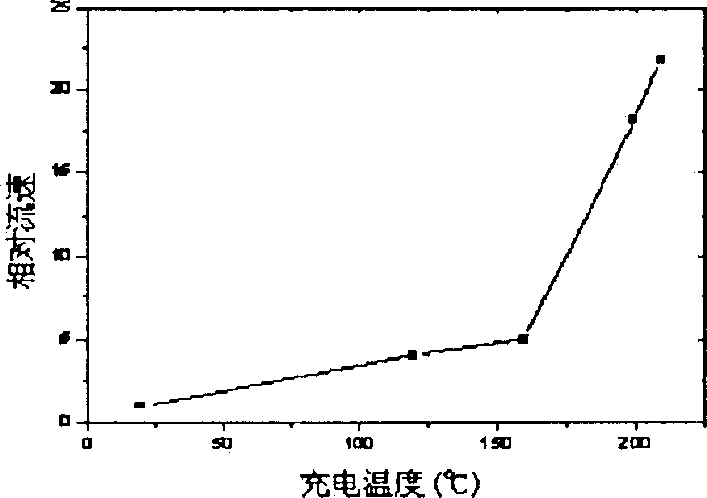

[0020] Embodiment 1, adopt porous PTFE film, film thickness is 30 μ m, and the length of slit-like hole is 5 μ m, and slit width is 10 -1 μm, using corona charging: the voltage is ±15kV, the temperature is 100°C, the power-on time is 5min, the distance between the electrode and the film is 10cm, the electrodes are needle-shaped, and 5 electrodes are used.

Embodiment 2

[0021] Embodiment 2, adopt porous PTFE film, film thickness is 90 μ m, and the length of slit-like hole is 25 μ m, and slit width is 10 -1 μm, using corona charging: the voltage is ±50kV, the temperature is 300°C, the power-on time is 15min, the distance between the electrode and the film is 45cm, the electrodes are needle-shaped, and 15 electrodes are used.

Embodiment 3

[0022] Example 3, using a porous PTFE film with a film thickness of 70 μm, a slit-like hole length of 35 μm, and a slit width of 1.5 μm, using corona charging: the voltage is ±30 kV, the temperature is 250 ° C, and the electrification time is 20 minutes. The membrane distance is 25cm, and the electrodes are needle-shaped, with 280 electrodes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com