Apparatus for producing coal-water fluid or oil-coal fluid and production method thereof

A technology for producing coal-oil slurry and water, which is applied in the field of equipment for producing coal-water slurry, can solve the problems of large equipment investment, long process flow, and poor economy, and achieve the effects of small equipment investment, short process flow, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

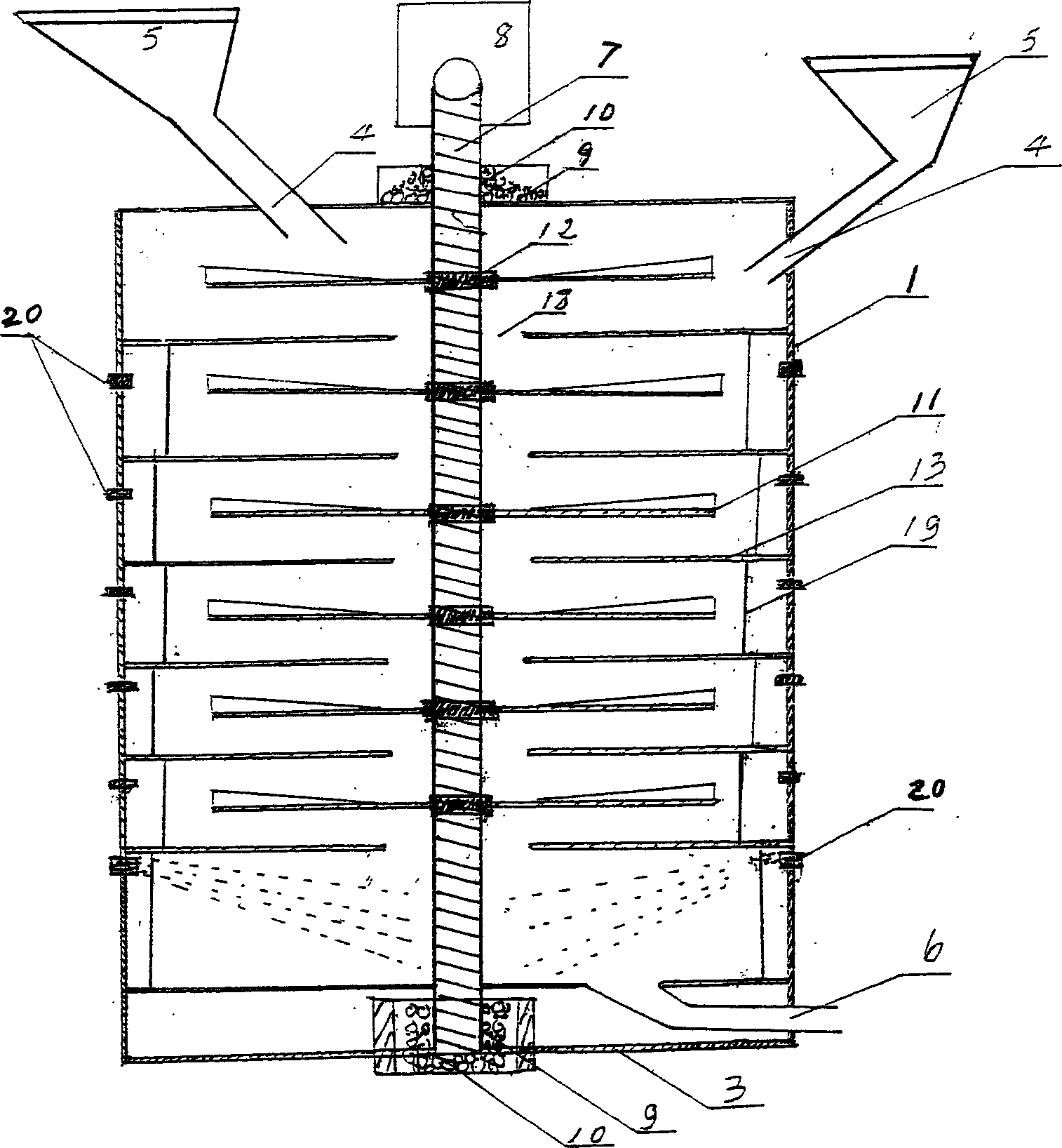

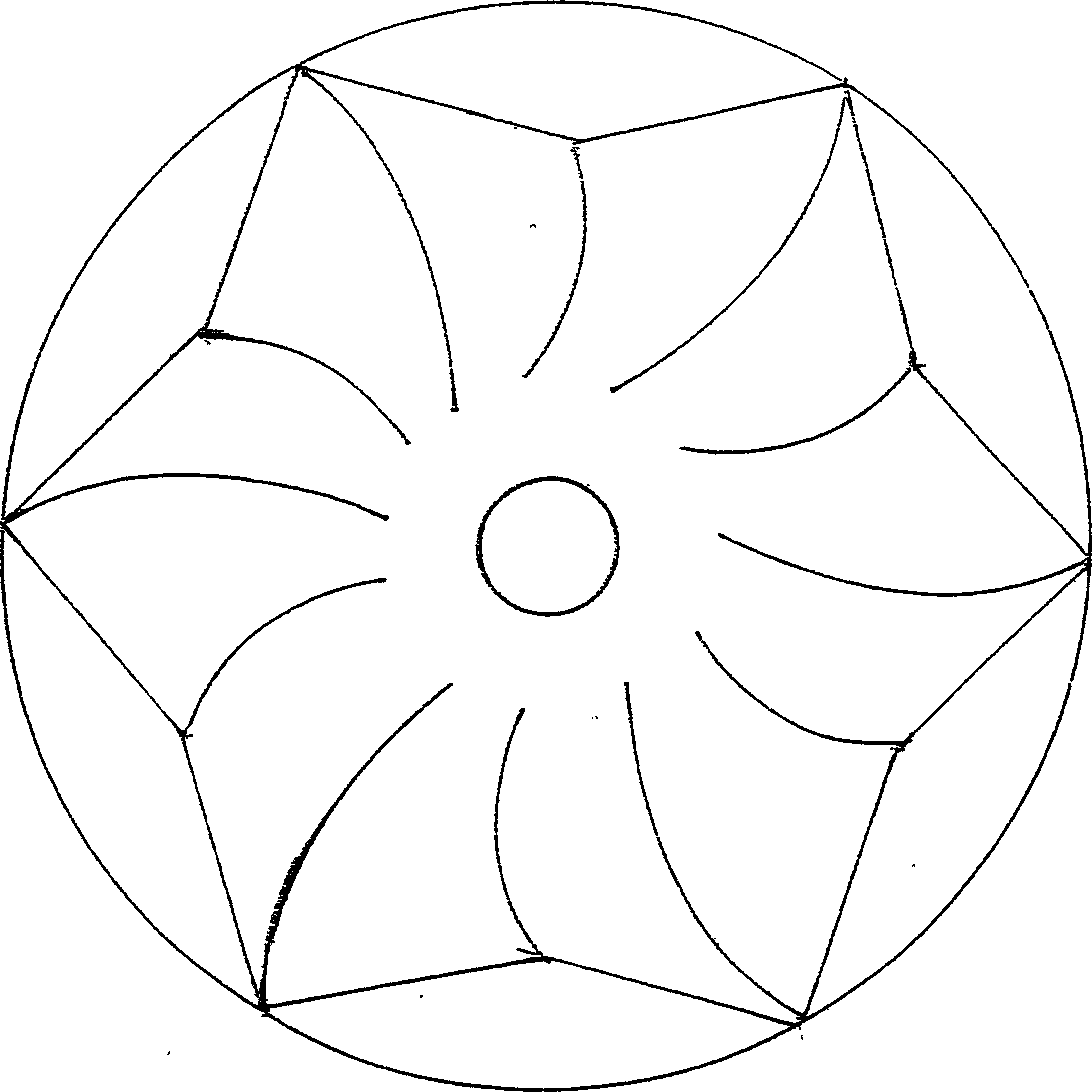

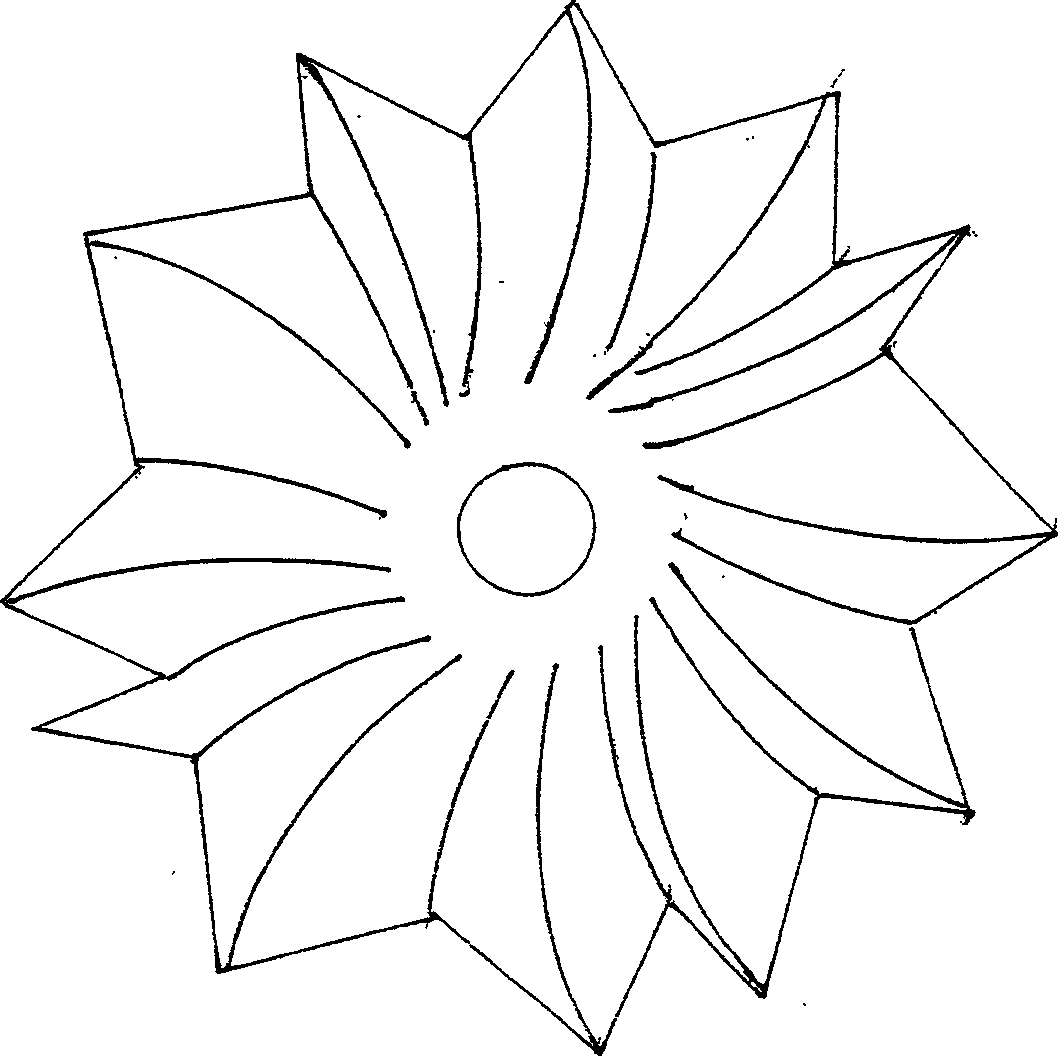

[0023] The coal-water slurry production equipment provided by the invention is made of wear-resistant polished stainless steel. It is 1.5 meters high and 0.5 meters in diameter. It is equipped with 8 layers of rotors and 8 layers of orifice plates. The rotational speed of the rotatable shaft can be controlled at 3000-5000 rpm. figure 2 ), the blade is a regular wedge-shaped arc-shaped surface (such as Figure 4 ), the feed size of raw coal is about 10-20 cm, and the amount of water injected is 40% (based on the total weight of the product coal-water slurry). After passing through the equipment, it will eventually become a coal-water slurry containing 200-300 mesh fine coal particles from the discharge port , can be directly transported to the power plant and directly used as fuel for the power plant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com