Automatic control method of blast-furnace top pressure stability for blast-furnace gas top pressure power generation apparatus

A technology of residual pressure power generation and blast furnace gas, applied in blast furnaces, blast furnace details, furnaces, etc., can solve problems such as reducing control time, and achieve the effects of increasing share, increasing technical content, and improving core competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

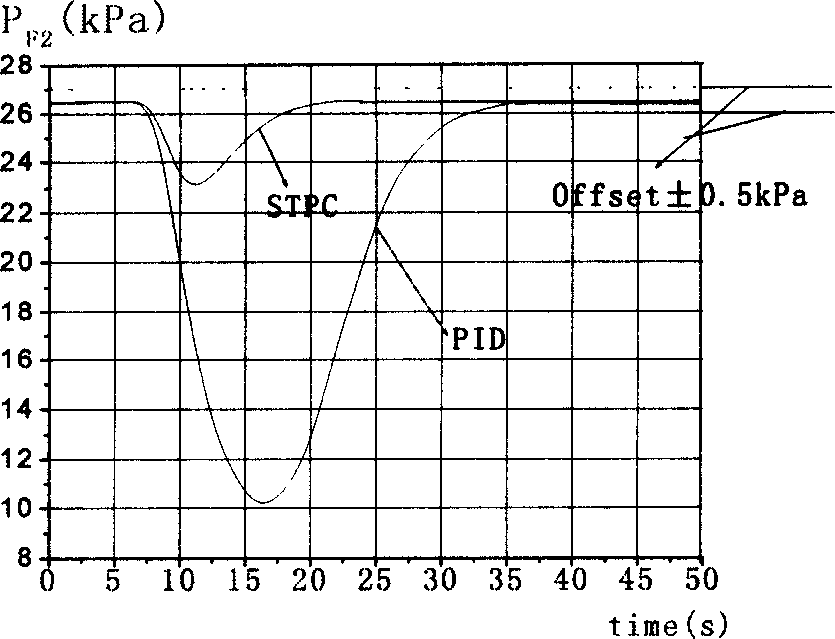

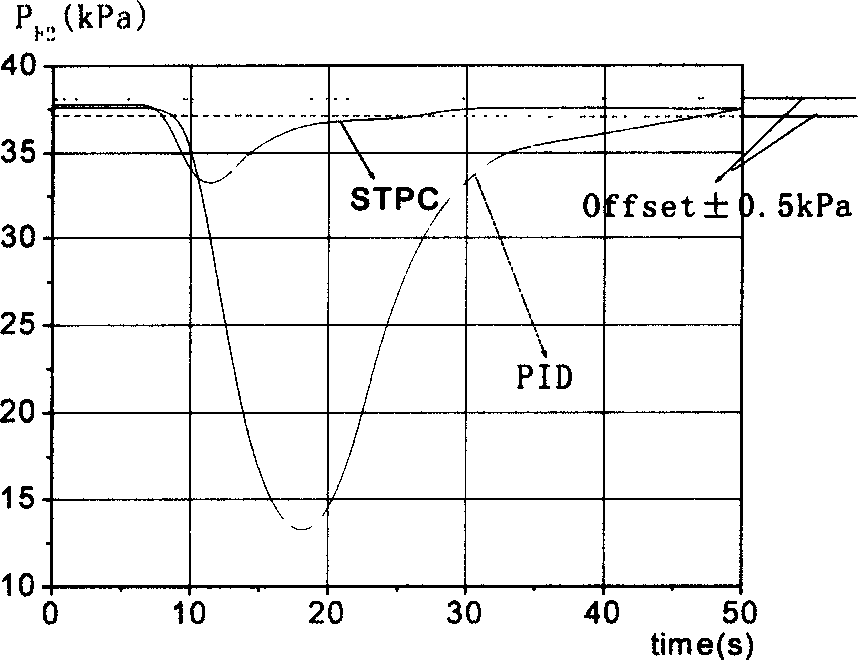

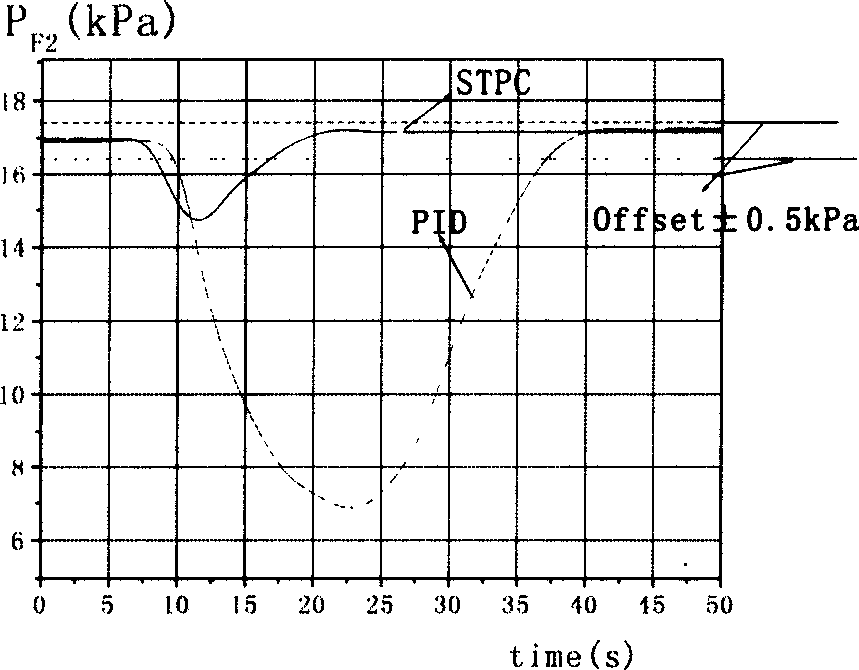

[0144] According to the technical solution of the present invention, the applicant has prepared a TRT top pressure stability test and research device. see Figure 6 , the blast furnace gas residual pressure power generation device blast furnace top pressure stability control test device, including a wind source fan 1, the wind source fan 1 is composed of a fan stator, a fan rotor, and a fan transmission group; the device also includes the following components:

[0145] A blast furnace model device 2, which is composed of a blast furnace model and a regulating valve v01. The regulating valve v01 is set on the blast furnace model. The regulating valve v01 can generate sine, cosine, square wave, and composite wave to realize various disturbance simulations in the blast furnace smelting process ;

[0146] A system pipeline 3 and a plurality of valve components, test measurement points are arranged on the system pipeline, pressure sensors PT01, PT02, PT03, PT04, PT05, temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com