Catalyst for preparing carbon nanometer pipe with small pipe diameter

A technology of carbon nanotubes and single-walled carbon nanotubes, which is applied in the field of inorganic material synthesis, can solve the problems of high degree of graphitization, changing the preparation conditions of carbon nanotubes, and inability to improve the yield and purity of single-walled carbon nanotubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

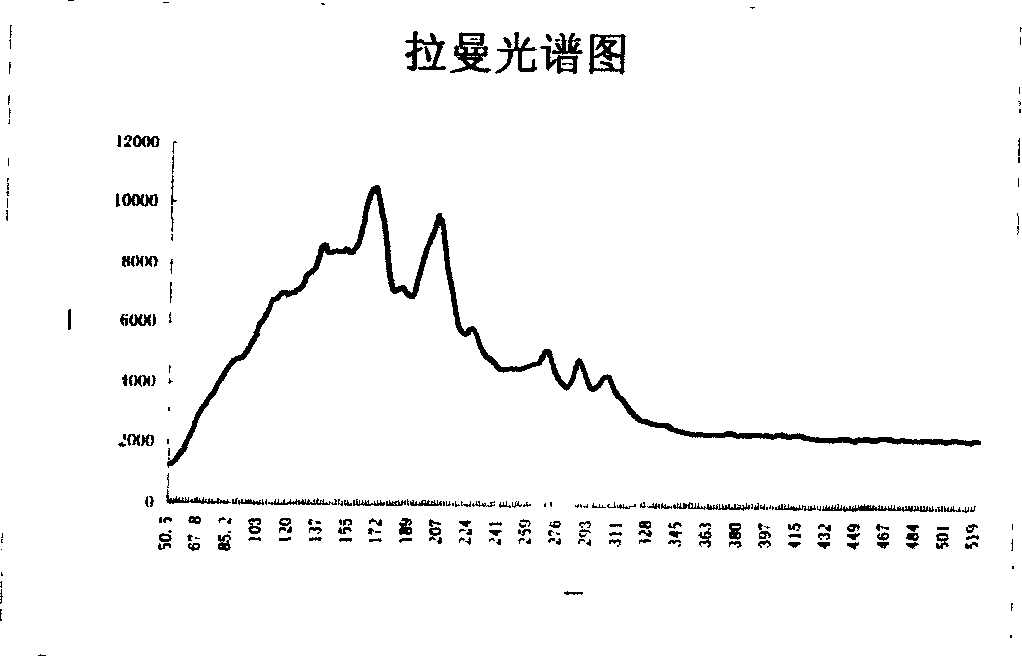

[0020] Catalyst composed of Co 0.1 Sr 0.04 Mo 0.05 Mg 0.94 O. Weigh 0.100 g of the catalyst and place it in a molybdenum boat, and the molybdenum boat is placed in the middle of a tubular reactor (35 mm in diameter). First pass nitrogen to remove the air, half an hour later, under the protection of nitrogen, start to heat up, and switch to the mixed gas of hydrogen and methane after reaching 750 °C, H 2 Flow 100ml / min, CH 4 The flow rate is 40ml / min. The heating rate was 5°C per minute. After reacting for 50 minutes, switch the mixed gas of hydrogen and methane to nitrogen, and cool to room temperature. Weighed 0.218 g of black product, yield 118%. After purification with nitric acid, the purity of the single-walled carbon nanotubes reaches 98% (weight percentage), and the yield is 0.106g. After Raman spectrum analysis, the diameters of the obtained single-wall carbon nanotubes are mainly concentrated in 1.1-1.5nm. The transmission electron microscope photo of the ob...

Embodiment 2

[0022] Catalyst composed of Co 0.04 Cu 0.02 Mo 0.01 Fe 0.01 Mg 0.94 O. Weigh 0.100 g of the catalyst and place it in a molybdenum boat, and the molybdenum boat is placed in the middle of a tubular reactor (35 mm in diameter). First pass nitrogen to remove the air, and after half an hour, start to heat up under the protection of nitrogen, and switch to pure methane after reaching 900°C, CH 4 The flow rate is 60ml / min. Cool to room temperature after reacting for 60 minutes. Weighed 0.233 g of black product, yield 133%. After purification with nitric acid, the purity of the single-walled carbon nanotubes reaches 95% (weight percentage), and the yield is 0.113g. After Raman spectrum analysis, the diameters of the obtained single-wall carbon nanotubes are mainly concentrated in 0.9-1.3nm.

Embodiment 3

[0024] Catalyst composed of Co 0.1 Ca 0.05 Mo 0.01 Mg 0.94 O. Weigh 0.100 g of the catalyst and place it in a molybdenum boat, and the molybdenum boat is placed in the middle of a tubular reactor (35 mm in diameter). First pass nitrogen to remove the air, half an hour later, under the protection of nitrogen, start to heat up, and switch to the mixed gas of hydrogen and methane after reaching 800°C. 2 Flow 40ml / min, CH 4 The flow rate is 80ml / min. The heating rate was 4°C per minute. After reacting for 50 minutes, switch the mixed gas of hydrogen and methane to nitrogen, and cool to room temperature. Weighed 0.603 g of black product, yield 503%. The purity of the small-diameter multi-walled carbon nanotubes obtained after purification with nitric acid reaches 96% (weight percentage), and the yield is 0.483g. Through transmission electron microscope observation, the outer diameter of carbon nanotubes is mainly concentrated in 3-8nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com