Magnetic particle mfg. method, magnetic particle and magnetic recording medium

A magnetic particle and manufacturing method technology, applied in magnetic recording, magnetic layer, data recording, etc., can solve the problems of small size, good monodispersity, uneven stirring of the solution, etc., and achieve the effect of excellent self-alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

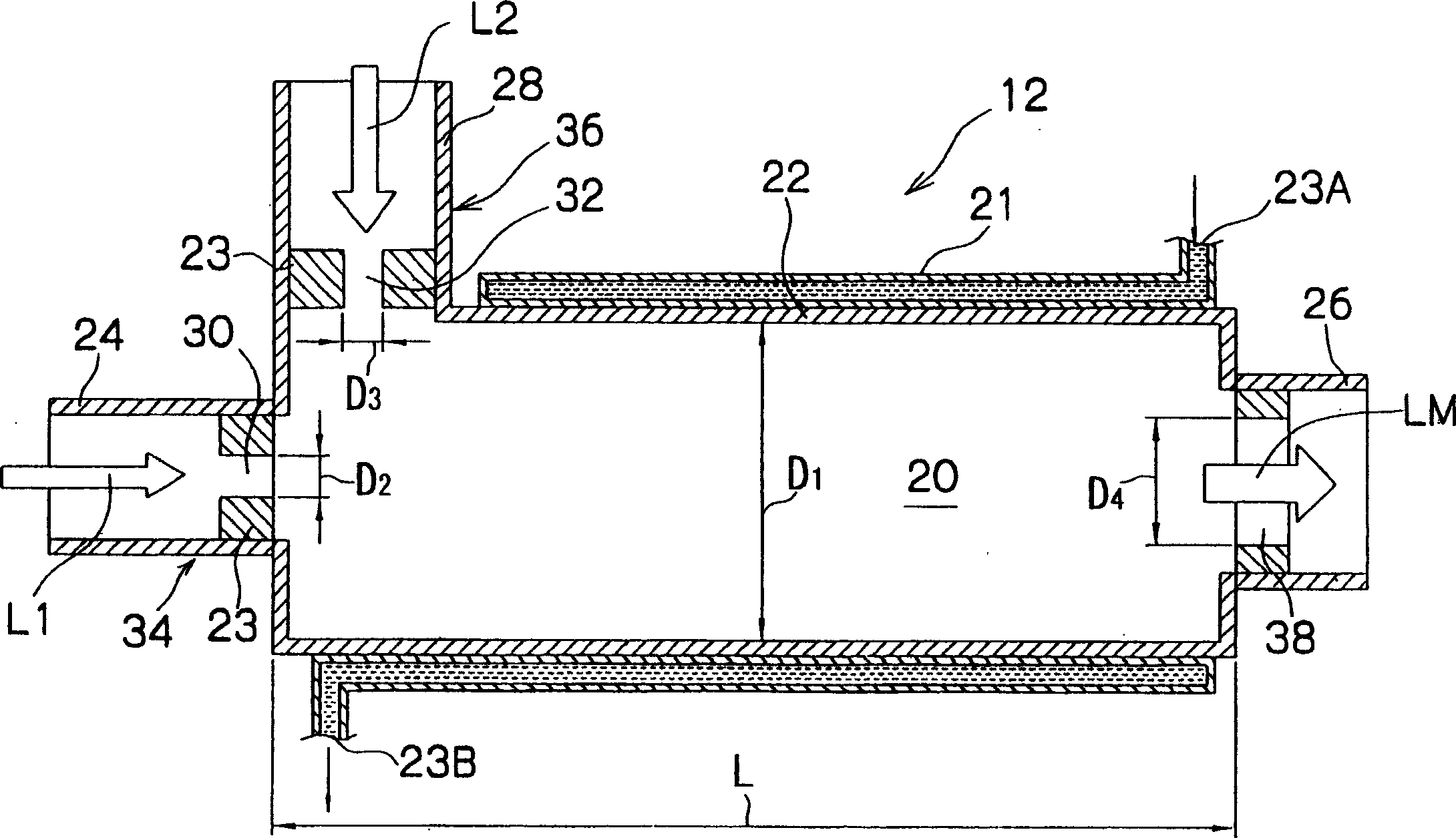

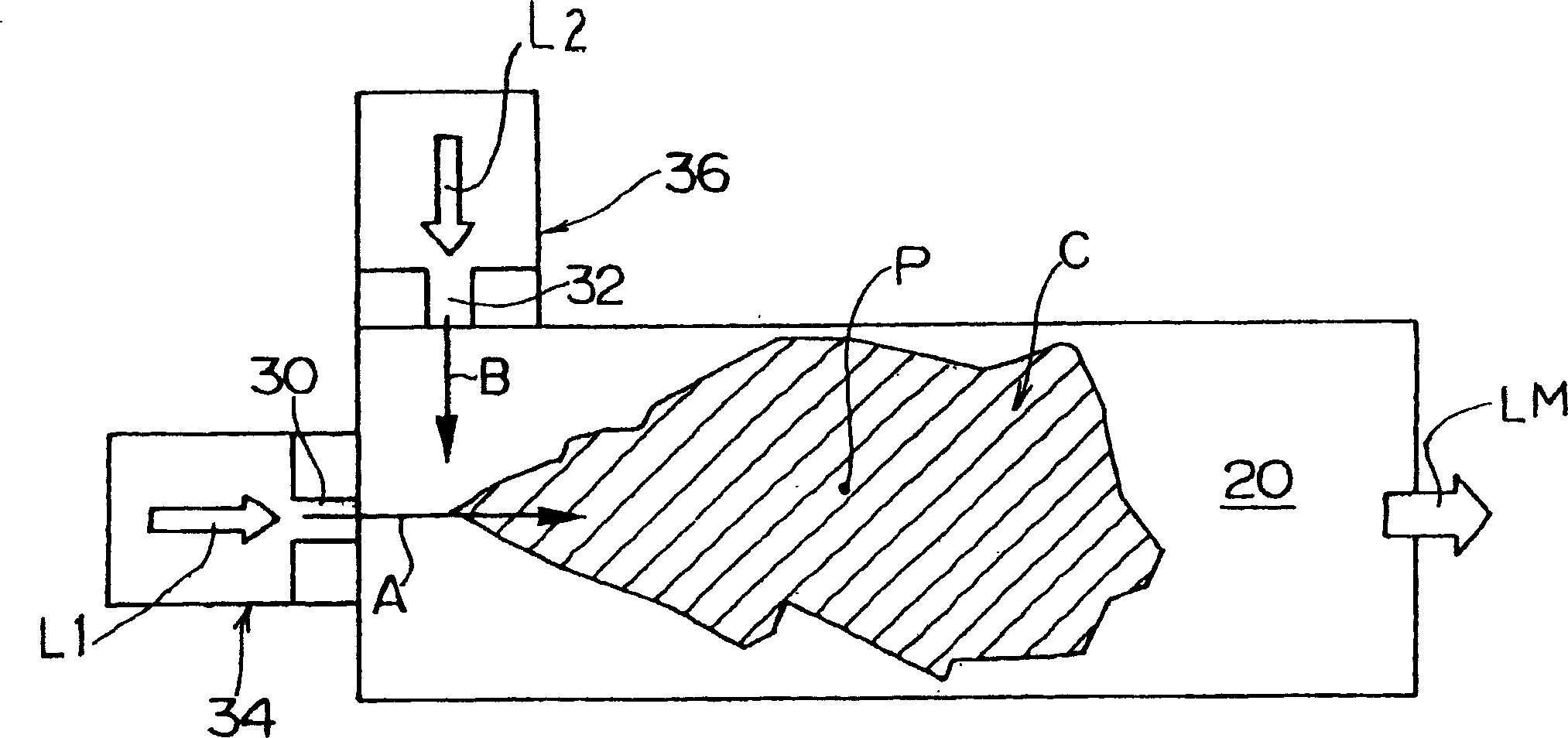

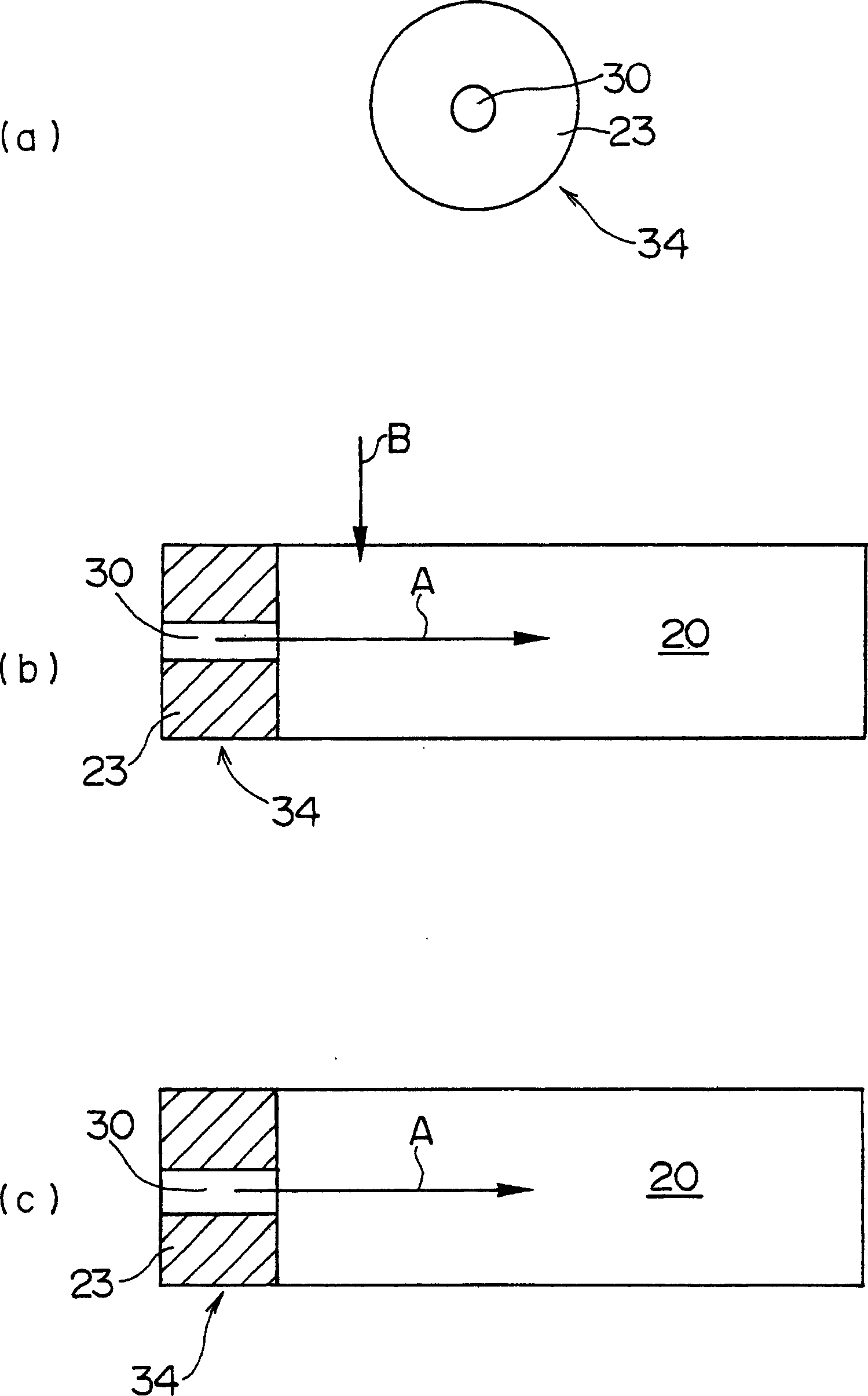

[0090] Preferred embodiments of the method for producing magnetic particles, the magnetic particles, and the magnetic recording medium of the present invention will be described in detail below with reference to the accompanying drawings.

[0091] The manufacturing method of the magnetic particles of the present invention comprises an alloy particle manufacturing process of manufacturing alloy particles capable of forming a hard magnetic ordered alloy phase by a liquid phase method, and forming a CuAu type or a Cu alloy particle from the manufactured alloy particles. 3 The composition of the magnetic particle formation process of Au type magnetic particles.

[0092] Next, the method for producing the magnetic particle and the magnetic particle of the present invention will be described while describing each of the above-mentioned steps. In addition, the annealing treatment is used as an example to describe the magnetic particle forming process below, but it is not limited ther...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com