Improved high-temperature central body utilizing light reflection to reduce temperature and its manufacturing method

A center body and mirror reflection technology, applied in the direction of combustion method, sustainable transportation, high-efficiency propulsion technology, etc., can solve the problem of insufficient TBCs and achieve the effect of shortening the life of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

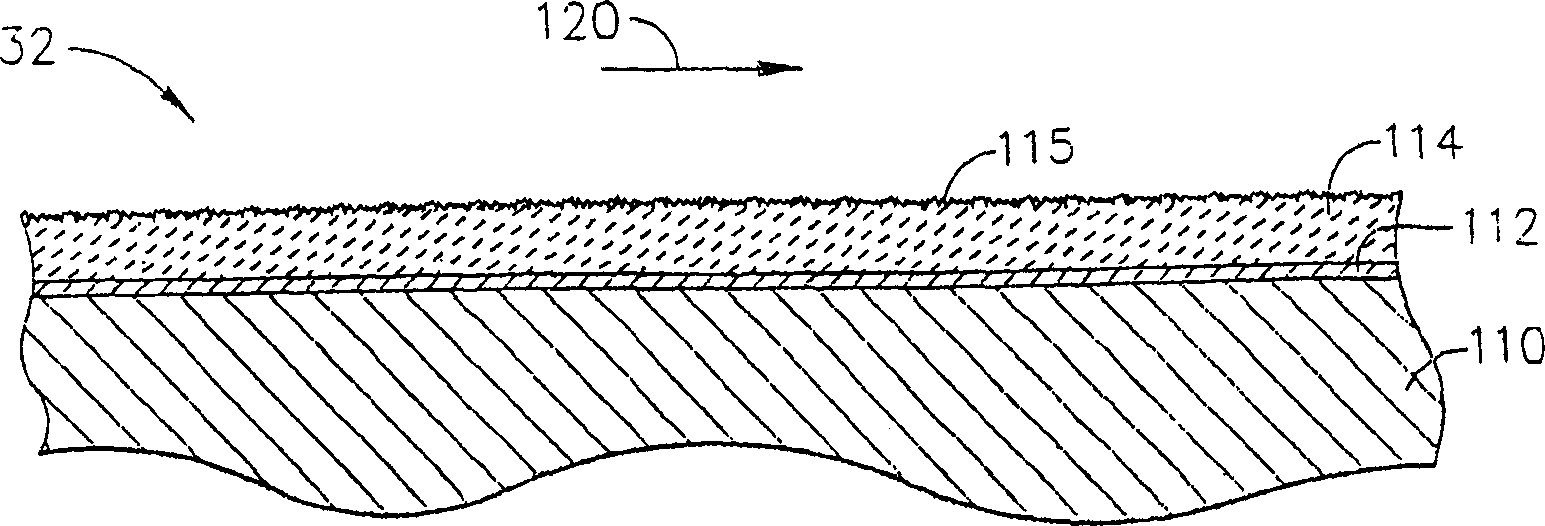

[0019] According to the present invention, a hot section member of a gas turbine constituting a gas flow path or disposed in the gas flow path is applied with a specular light reflection thin layer material having high temperature properties. The applied material has a smooth surface finish that mirrors thermal energy back into the fluid channels and away from other thermal section components.

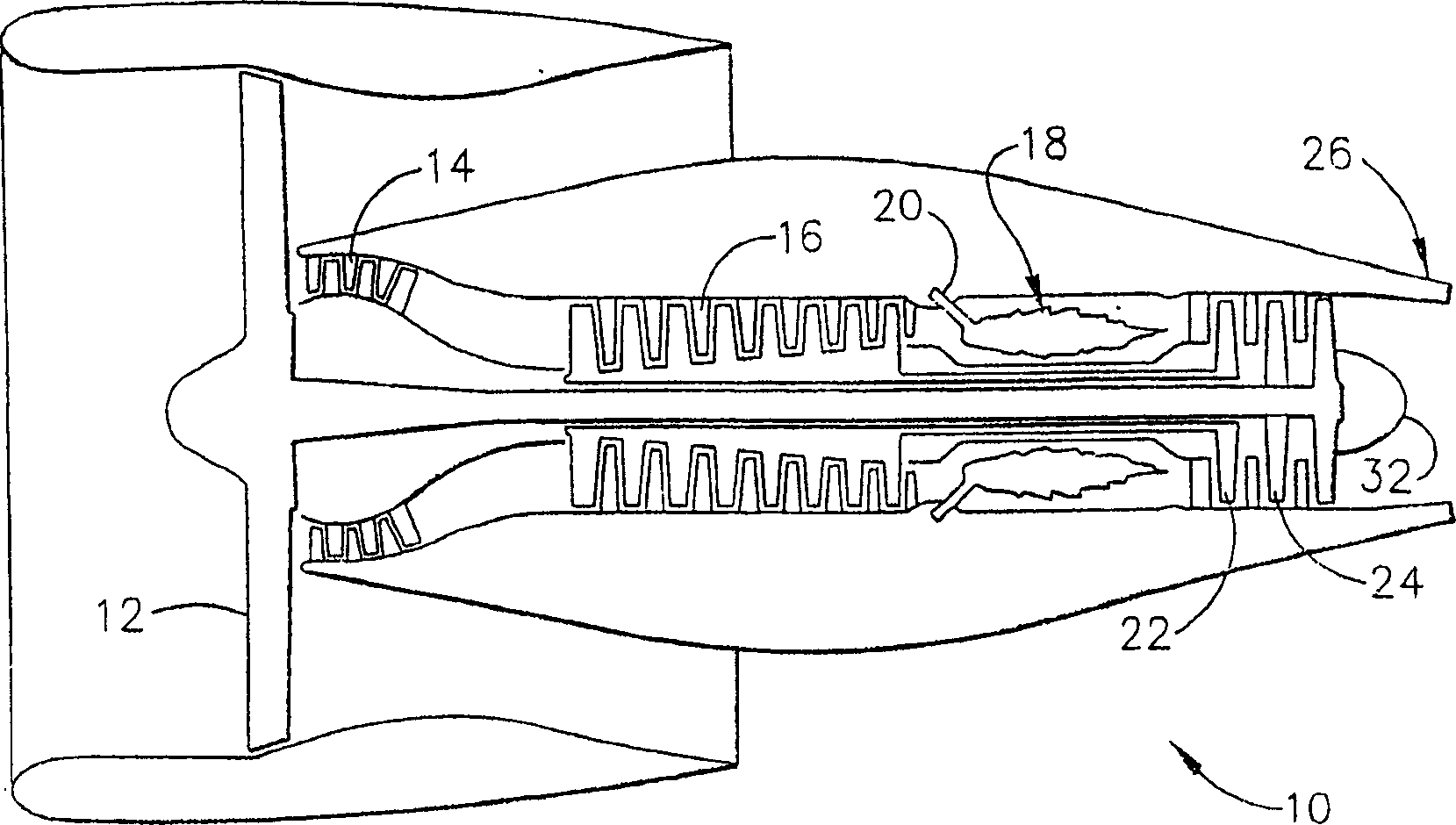

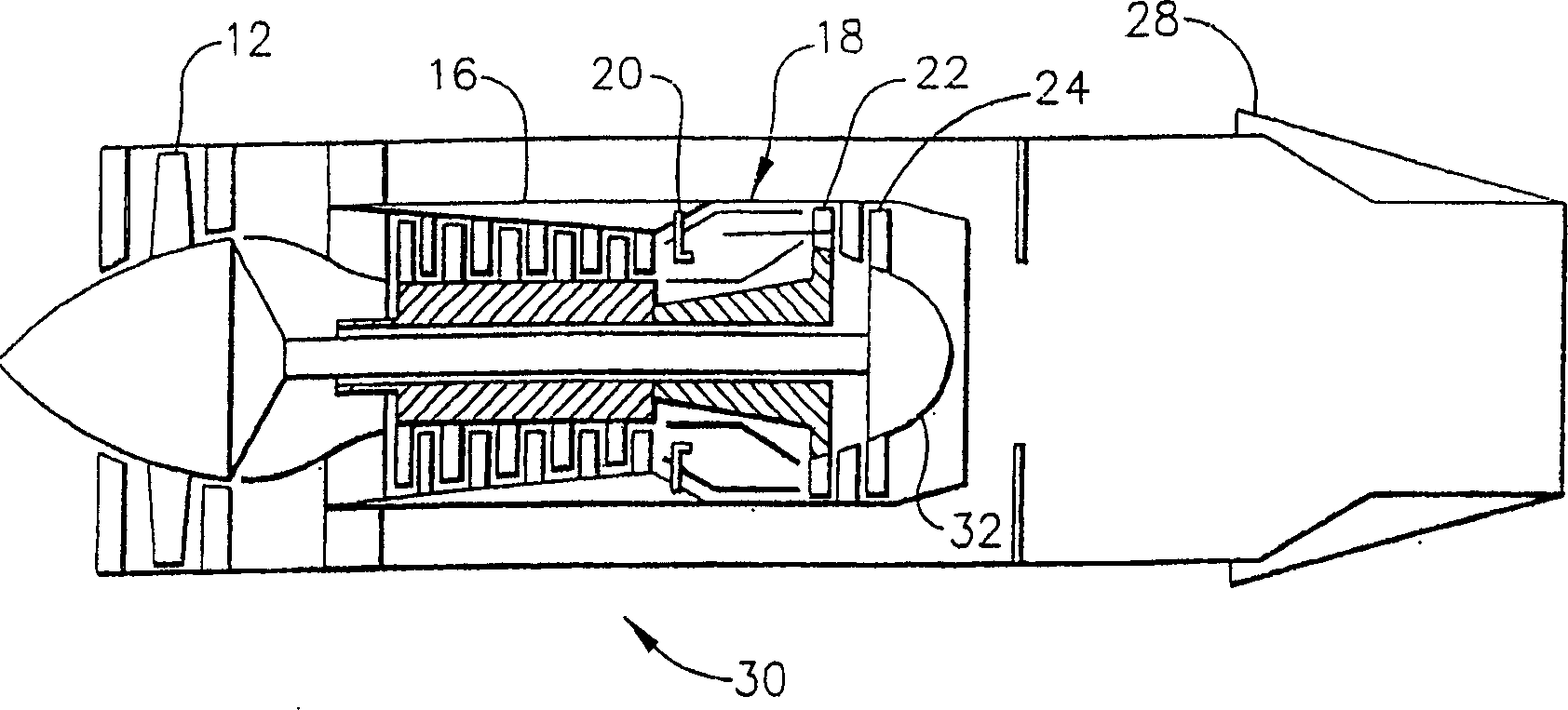

[0020] figure 1 is a schematic diagram of a high bypass ratio aircraft gas turbine 10 . During operation, air is forced through the fan 12 . A portion of the air bypasses the center of the engine and creates the thrust that propels the engine. A portion of the air is compressed to 10-25 times atmospheric pressure in the engine's supercharger 14 and compressor 16 sections, and is adiabatically heated to 800-1250°F (430-680°C) in the process. This heated and compressed air enters the combustion chamber portion 18 of the engine and mixes with fuel supplied via a fuel nozzle system 20 ....

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com