SiO2 potassium silicate atomic oxygen resistant paint and its preparation method

A technology of protective coating and potassium silicate, which is applied in the direction of coating, etc., can solve the problems of poor adaptability to the volume change of the substrate, achieve strong anti-ultraviolet radiation ability, significant anti-atomic oxygen effect, and improve compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

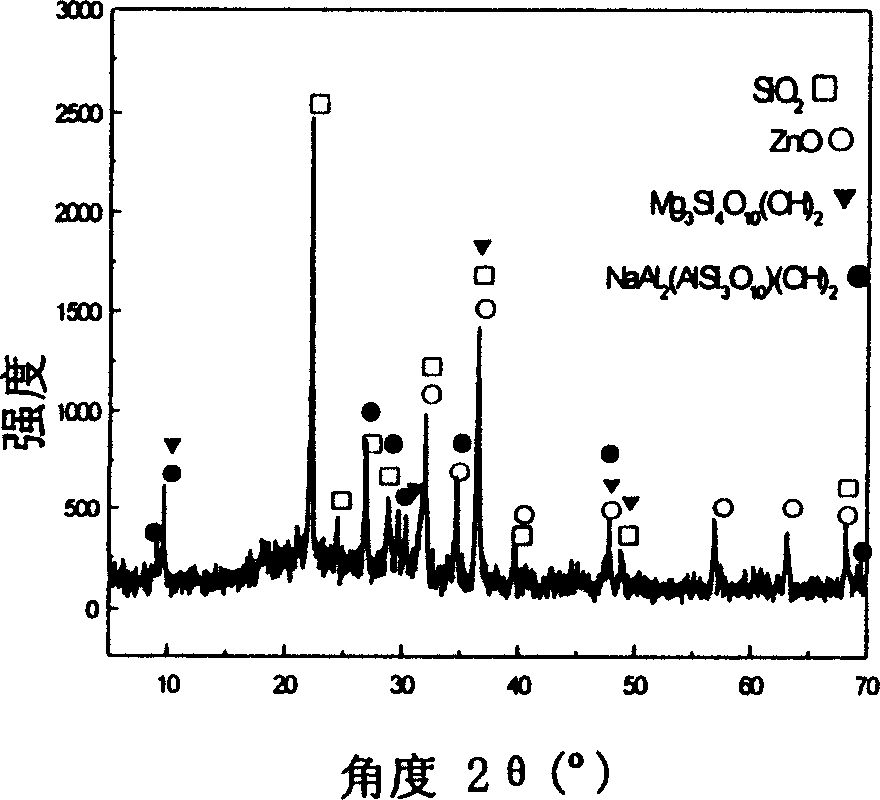

[0026] Put 80g of potassium silicate and 200g of water into the stirring tank, start the mixer and stir evenly, then add 2g of stabilizer diethanolamine and stir evenly, dilute the industrial sulfuric acid into 10% (volume concentration) dilute sulfuric acid, and slowly add it to the stirring tank In the method, the pH value is controlled in the range of 11-13, and the addition amount is 2 g to obtain the acid-modified water glass base material. Sodium hexametaphosphate 1.5g is dissolved into 10% aqueous solution and is dropped in the stirring tank, then drops into antifoaming agent polyether modified methyl polysiloxane 1.5g (produced from German Bayer company, product model is VP3468) and 2 g of ND type dispersant (a phosphate / amine compound, manufactured by Bayer, Germany) was stirred evenly. Put 15g of light calcium carbonate, 40g of heavy calcium carbonate, 15g of talcum powder, 15g of mica, 28g of zinc oxide and 150g of silicon oxide into a mixing tank for dispersion, an...

Embodiment 2

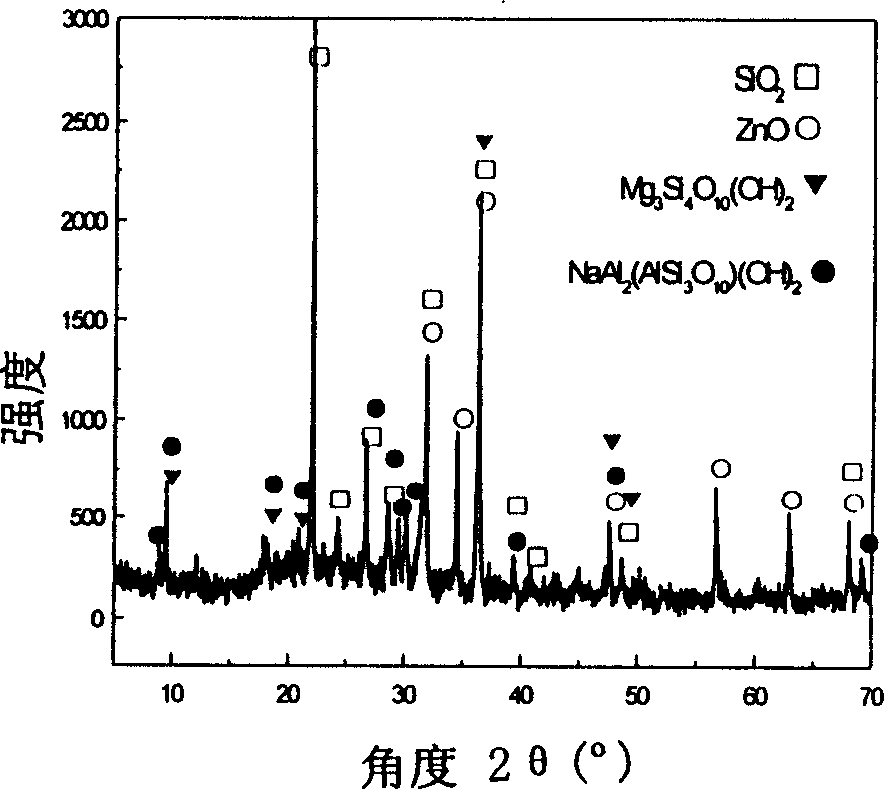

[0028] Put 86g of potassium silicate and 180g of water into the mixing tank, start the mixer and stir evenly, then add 1.7g of stabilizer diethanolamine and stir evenly, dilute the industrial sulfuric acid into 10% (volume concentration) dilute sulfuric acid, slowly add to the stirring tank In the tank, the pH value is controlled in the range of 11 to 13, and the addition amount is 2.5 g to obtain the acid-modified water glass base material. Sodium hexametaphosphate 1g was dissolved into a 10% aqueous solution and dropped into a stirring tank, and then 1g of antifoaming agent polyether modified methylpolysiloxane (produced by Bayer Company in Germany, product model VP3468) and ND type 2 g of dispersant (phosphate / amine compound, manufactured by Bayer Company in Germany, ie) was stirred evenly. Put 25g of light calcium carbonate, 45g of heavy calcium carbonate, 25g of talcum powder, 25g of mica, 28g of zinc oxide and 140g of silicon oxide into a mixing tank for dispersion, and ...

Embodiment 3

[0030] Put 105g of potassium silicate and 200g of water into the mixing tank, start the mixer and stir evenly, then add 1.6g of stabilizer diethanolamine and stir evenly, dilute the industrial sulfuric acid into 10% (volume concentration) dilute sulfuric acid, slowly add to the stirring tank In the tank, the pH value is controlled in the range of 11 to 13, and the addition amount is 3g to obtain the acid-modified water glass base material. Sodium hexametaphosphate 1g is dissolved into 10% aqueous solution and dropped in the stirring tank, then drops into antifoaming agent polyether modified methyl polysiloxane 1.2g (produced in German Bayer company, product model is VP3468) and ND Type dispersant 2g (phosphate / amine compound, manufactured by Bayer Company in Germany) was stirred evenly. Put 20g of light calcium carbonate, 40g of heavy calcium carbonate, 20g of talcum powder, 20g of mica, 28g of zinc oxide and 180g of silicon oxide into a mixing tank for dispersion, and grind w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com