Optical-thermal coupling air purifier having honeycomb arrangement

A technology of air purifier and honeycomb structure, which is applied in the direction of air quality improvement, heating methods, household appliances, etc., which can solve the problems of insufficient purification efficiency and mineralization rate, which affect the application and promotion of photocatalytic air purifiers, and achieve mineralization High efficiency, small size, and improved purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

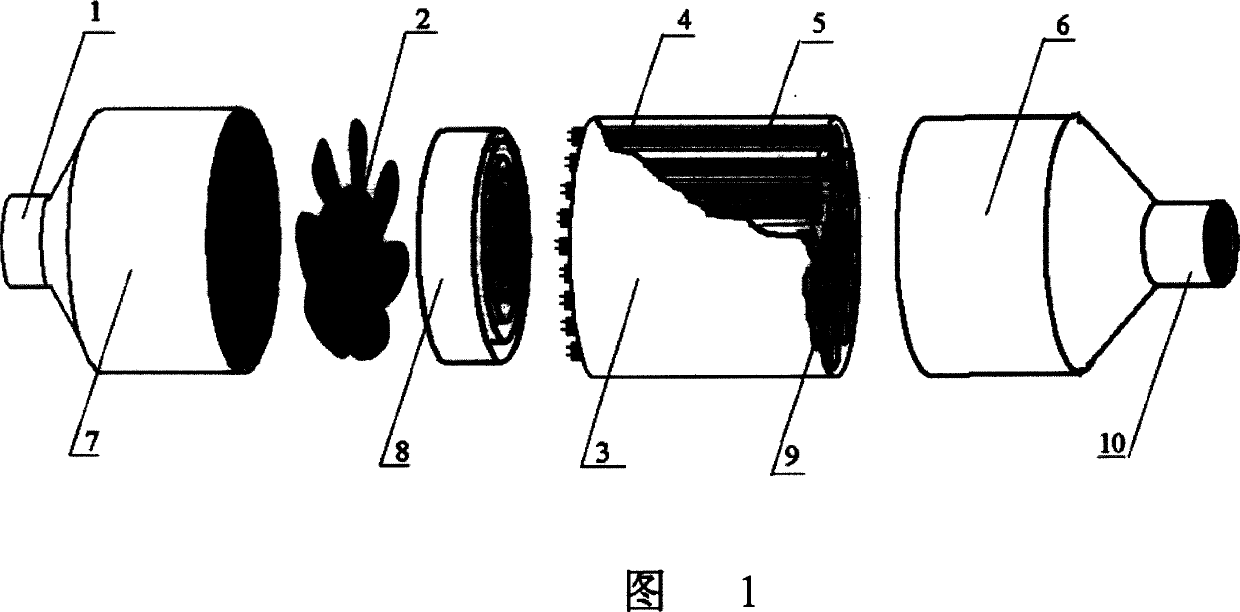

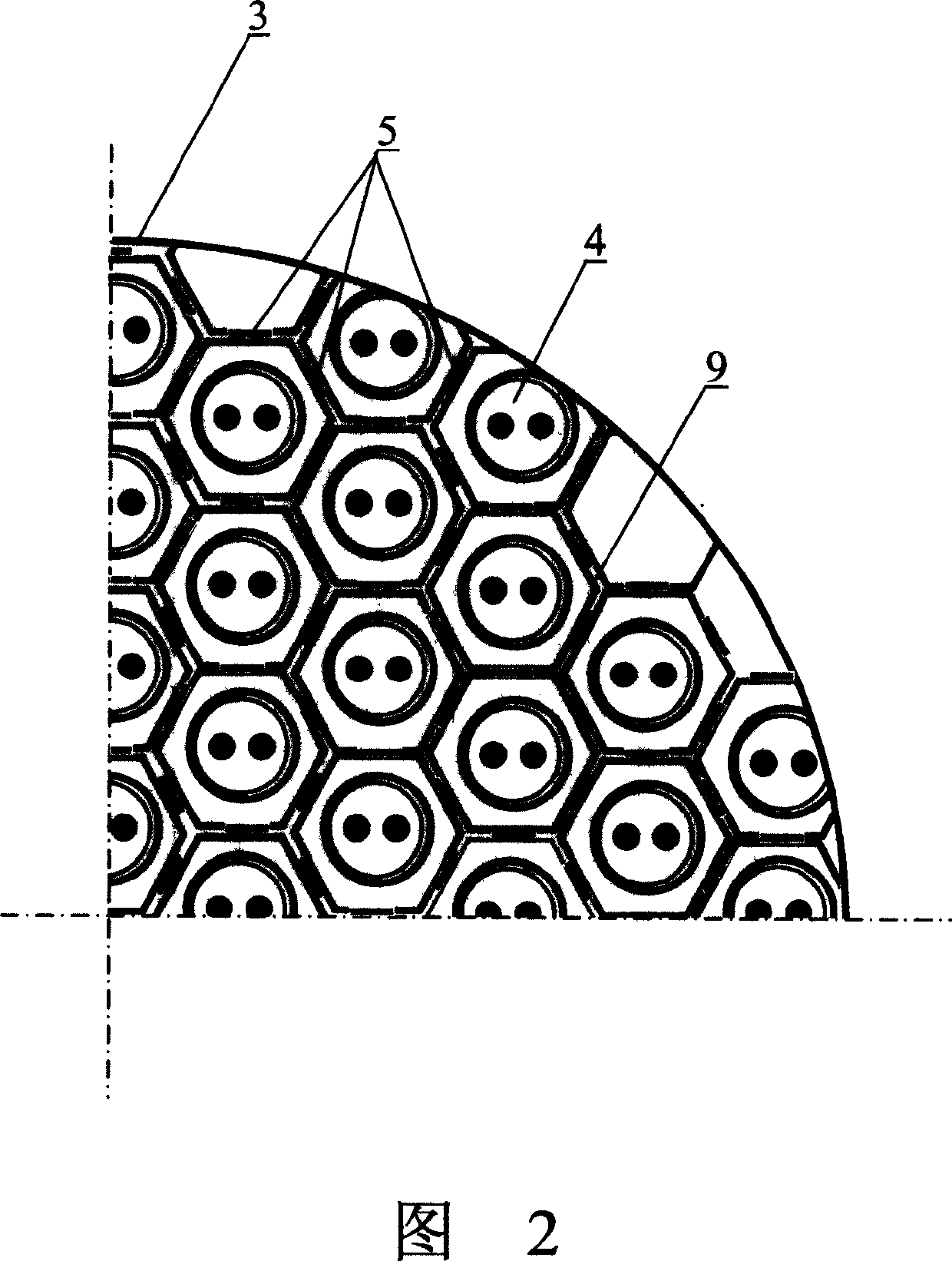

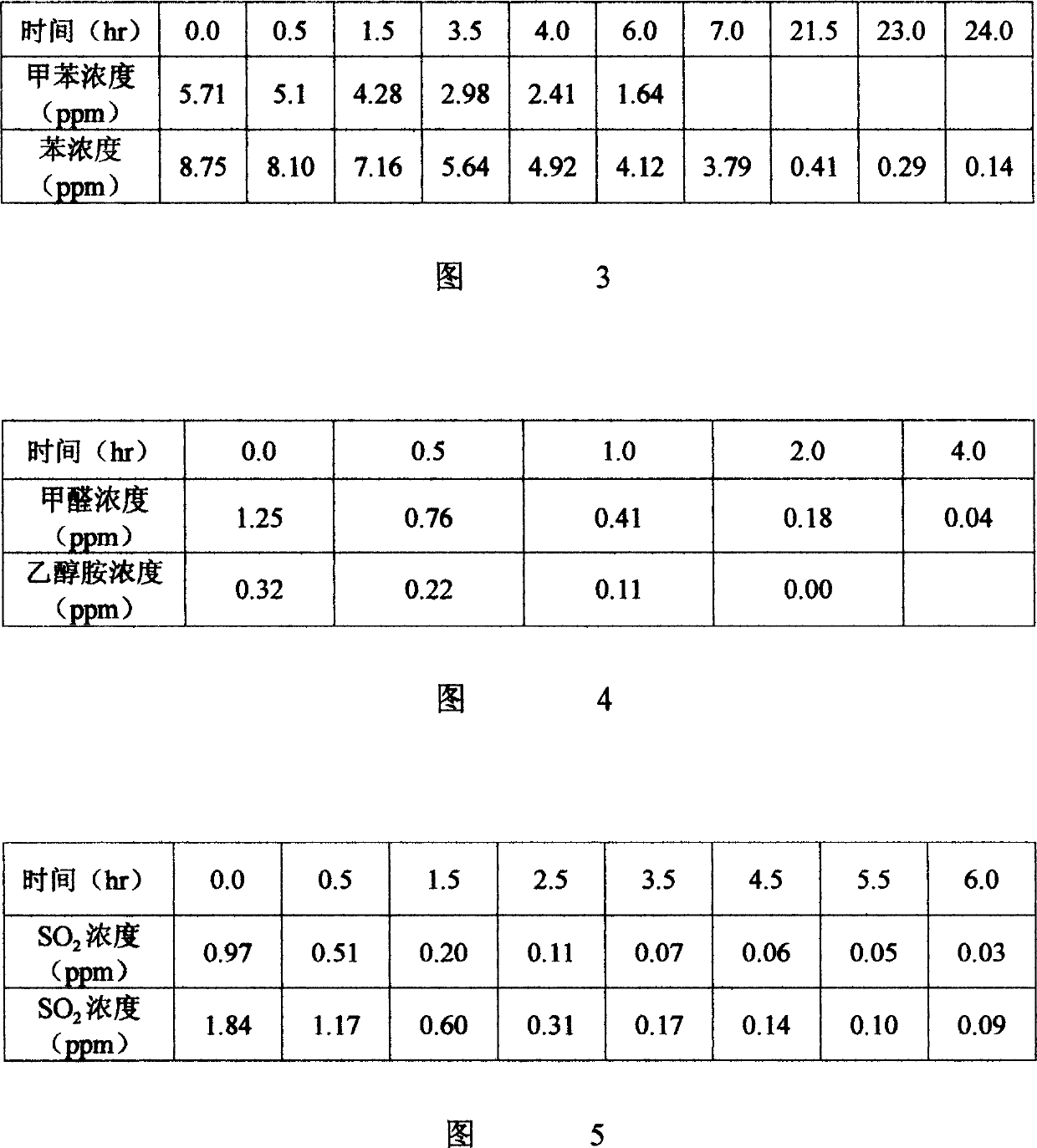

[0016] Please refer to Figure 1 and Figure 2, the honeycomb-shaped carrier material is metal aluminum, and the aluminum is made into a honeycomb with hexagonal holes. The surface is treated according to the method indicated in our previously applied patent 03102878, and coated with the photocatalyst specified in our previously applied patent 98115808, and the coating method is in accordance with the method provided in our previously applied patent 03102878. One end of the purifier is a front cover (7), the end of the front cover (7) is an air inlet (1), and the center of the front cover (7) is equipped with a fan (2) and a flow regulating plate (8) , the other end of the front cover is connected to the casing; a honeycomb photocatalytic reactor (9) is installed in the casing (3), a compact heating device (5) is installed between the honeycomb walls, and a honeycomb center is installed UV lamp (4); the other end of the casing (3) is connected with a back cover (6), and the othe...

Embodiment 2

[0018] Please refer to Figure 1. The honeycomb-shaped carrier material is stainless steel, and the electric heating device uses thin electric heating wires, and the heating power is 500W. Organic pollutants selected formaldehyde and ethanolamine. A stainless steel sheet is made into a honeycomb with pentagonal holes. One end of the purifier is a front cover (7), the end of the front cover (7) is an air inlet (1), and the center of the front cover (7) is equipped with a fan (2) and a flow regulating plate (8) , the other end of the front cover is connected to the casing; a honeycomb photocatalytic reactor (9) is installed in the casing (3), a compact heating device (5) is installed between the honeycomb walls, and a honeycomb center is installed UV lamp (4); the other end of the casing (3) is connected with a back cover (6), and the other end of the back cover (6) is an air outlet (10). The details of the degradation process are shown in Figure 4.

Embodiment 3

[0020] Please refer to Figure 1. The honeycomb carrier material is non-woven fabric, and the catalyst is directly heated by a UV lamp that generates heat during work. Select different initial concentrations of SO for inorganic pollutants 2 gas. The aluminum sheet is made into a honeycomb purifier with circular holes. One end of the purifier is the front cover (7), the end of the front cover (7) is the air inlet (1), and the center of the front cover (7) is A fan (2) and a flow regulating plate (8) are installed, and the other end of the front cover is connected to the casing; a honeycomb photocatalytic reactor (9) is installed in the casing (3), and a honeycomb photocatalytic reactor (9) is installed between the honeycomb walls. There is a compact heating device (5), and an ultraviolet lamp (4) is installed in the center of the honeycomb; the other end of the casing (3) is connected with a rear cover (6), and the other end of the rear cover (6) is an air outlet (10 ). The d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Hole length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com