Vaporizing system vacuumizing method for urea production

An evaporation system and vacuum pumping technology, which is applied in the field of vacuum pumping of urea evaporation system, can solve the problems of poor effect, damage to the air quality of the factory area, and low vacuum degree, etc., and achieve outstanding environmental benefits, significant income increase effect, and working pressure difference small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

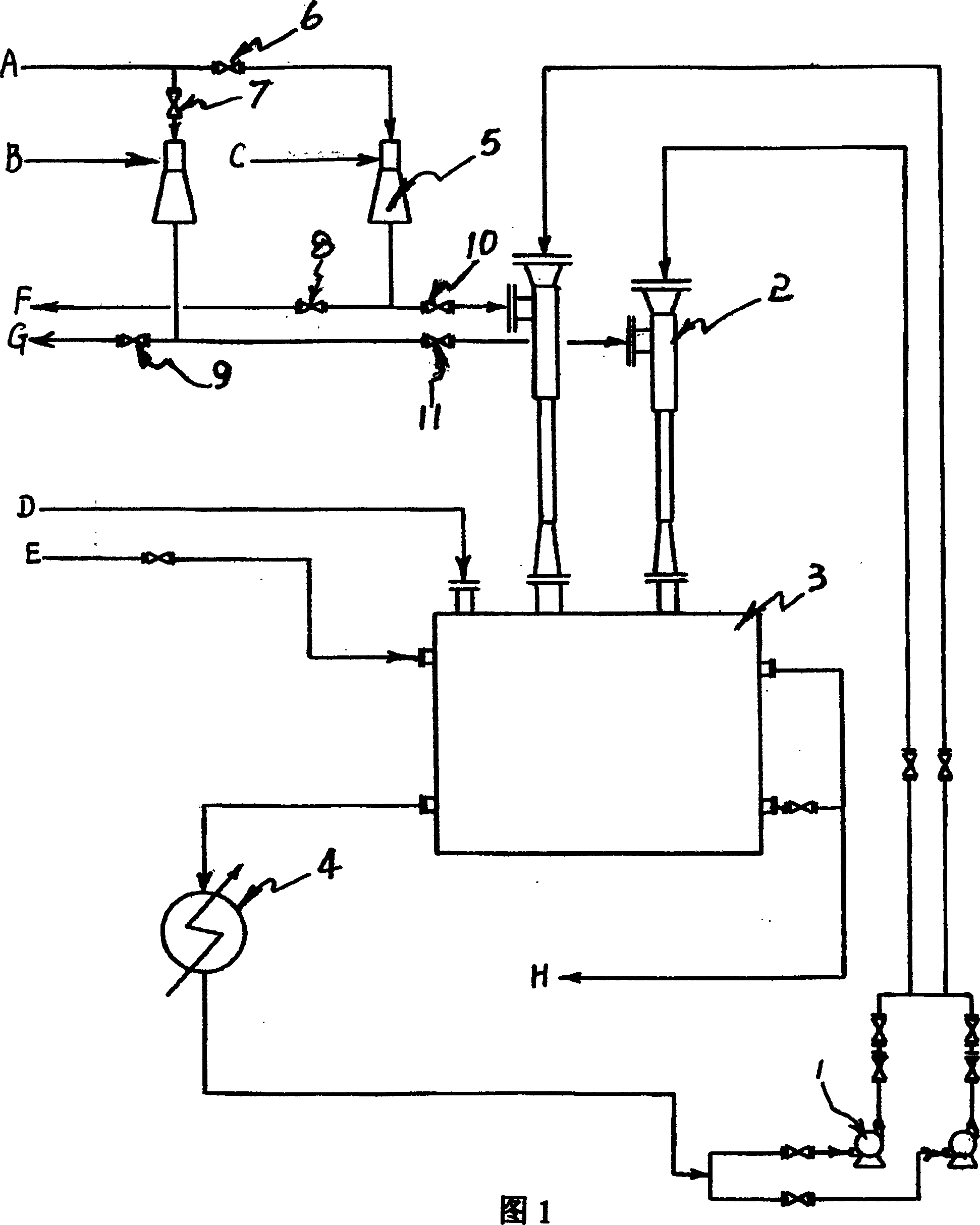

[0020] Referring to Fig. 1: implementing the method of the present invention, at first is to improve the vacuumizing device, make a closed-circuit circulation device connected by pipelines in order by pump 1, liquid-gas injector 2, circulation tank 3, replace steam vacuumizing The device is evacuated. The key part of the device is the injector 2, which is a specially designed and manufactured injector suitable for liquid media (disclosed in Chinese patent, publication number CN85102383A), and has the advantages of small operating pressure difference, high vacuum degree, and high efficiency. Implement the technical premise of the present invention.

[0021] Two liquid-gas ejectors 2 are connected in parallel, its medium inlet is connected with the outlet of pump 1, the outlet is connected with circulation tank 3, and the gas extraction port is respectively connected with the first-stage evaporative condenser and the intermediate condenser of the urea evaporation system. The pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com