Single-stage balanced ammonia-water reabsorption heat pump cycle equipment and heat supply method

A heat pump circulation and balance technology, applied in lighting and heating equipment, heat pumps, heating methods, etc., can solve the problems of low heat collection temperature, low ambient temperature, instability, etc., to achieve compact system structure and simple production process. , the effect of a wide temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

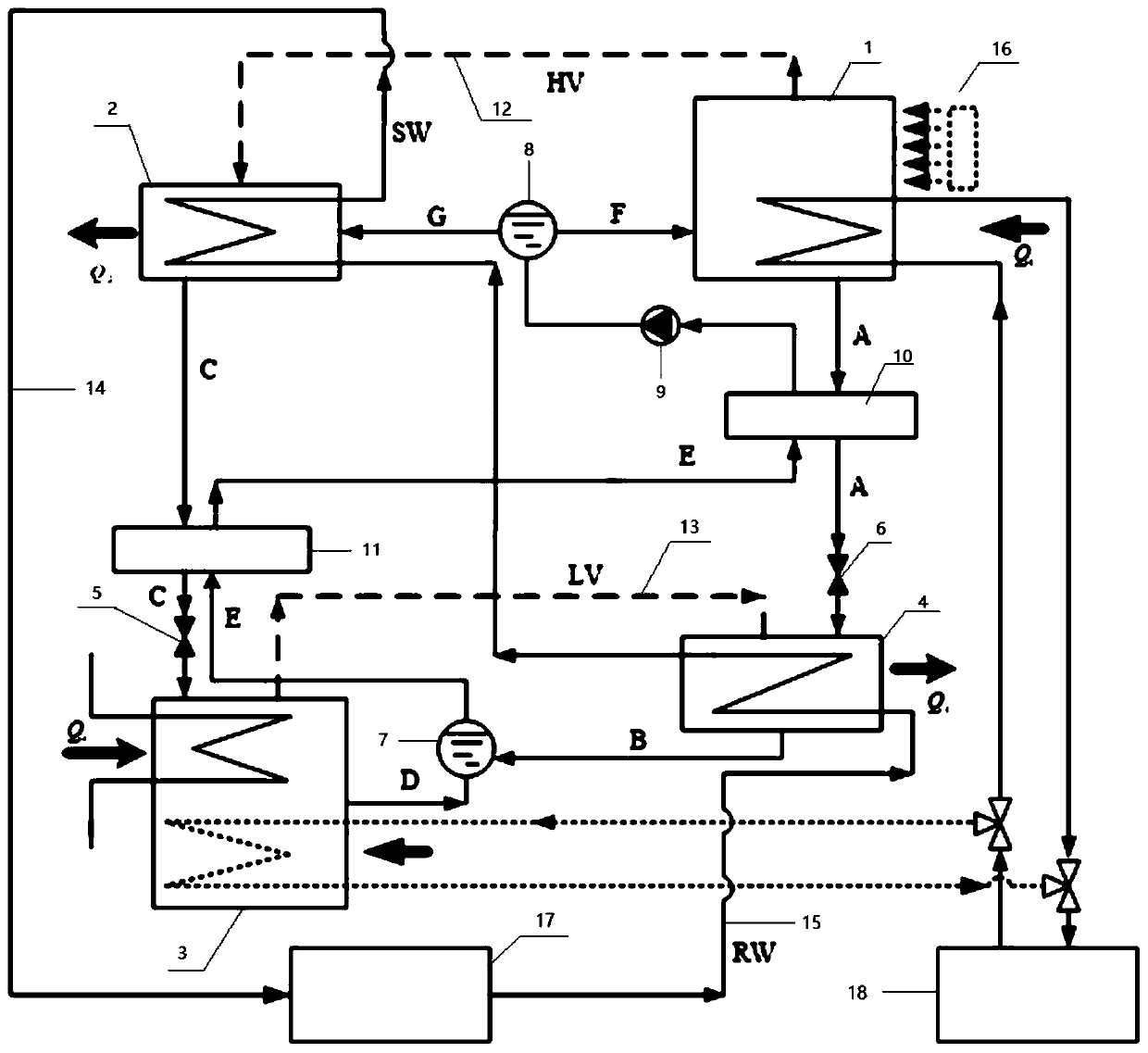

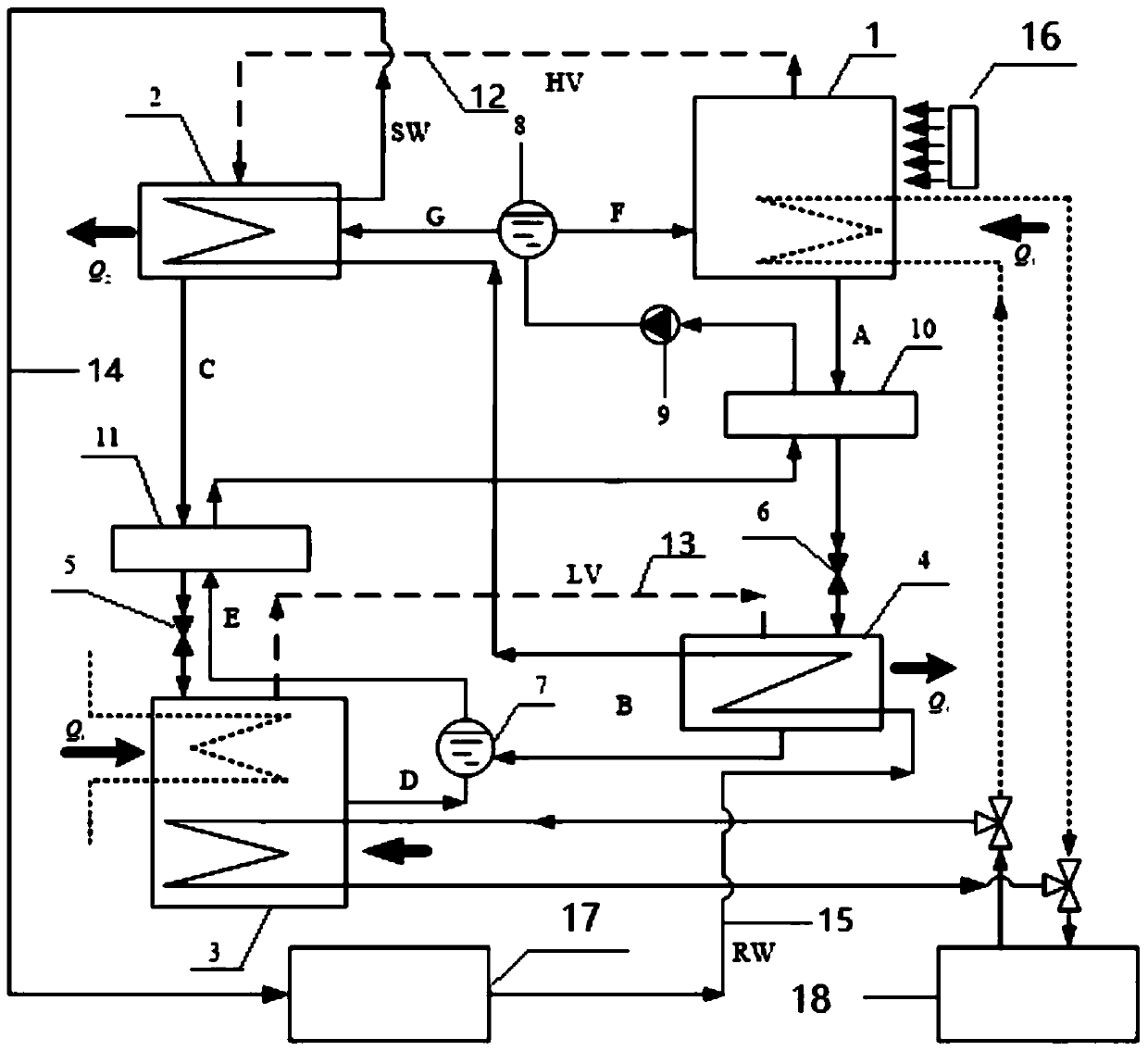

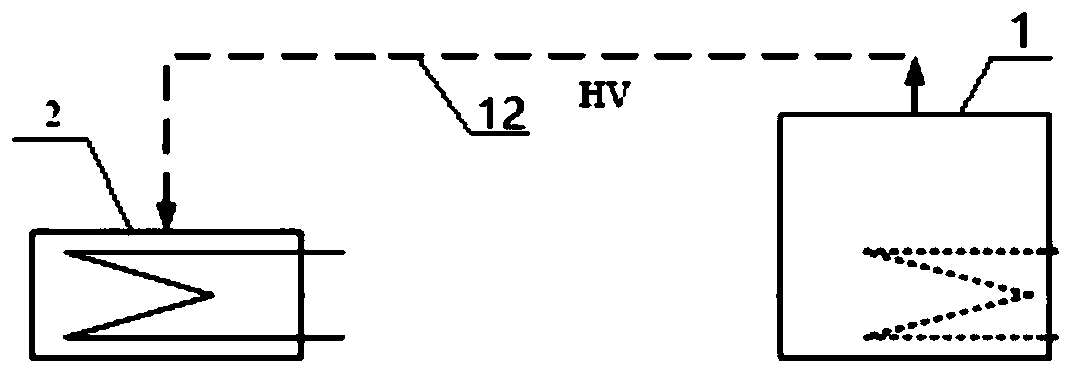

[0023] The structural diagram of the single-stage balanced ammonia-water reabsorption heat pump cycle equipment provided by the present invention is as follows: figure 1 or figure 2 As shown, it includes solution loop, refrigerant steam pipeline, water supply and return pipeline and driving heat source.

[0024] The working fluid in the solution loop of the single-stage balanced ammonia-water reabsorption heat pump circulation equipment is ammonia solution; the working fluid in the refrigerant steam pipeline is ammonia vapor; the working medium in the water supply and return pipeline is water. Specifically, the single-stage balanced ammonia-water reabsorption heat pump circulation equipment has 10 working fluids running at the same time, including 2 ammonia vapors, 7 ammonia solutions and 1 water (ie supply and return water). 2 streams of ammonia steam include high temperature and high pressure ammonia steam HV produced by high pressure generator and low temperature and low ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com