High power LED

A light-emitting diode, high-power technology, applied in electrical components, electric solid-state devices, circuits, etc., can solve the problems of large thermal resistance, small metal base area, overheating of light-emitting diodes, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

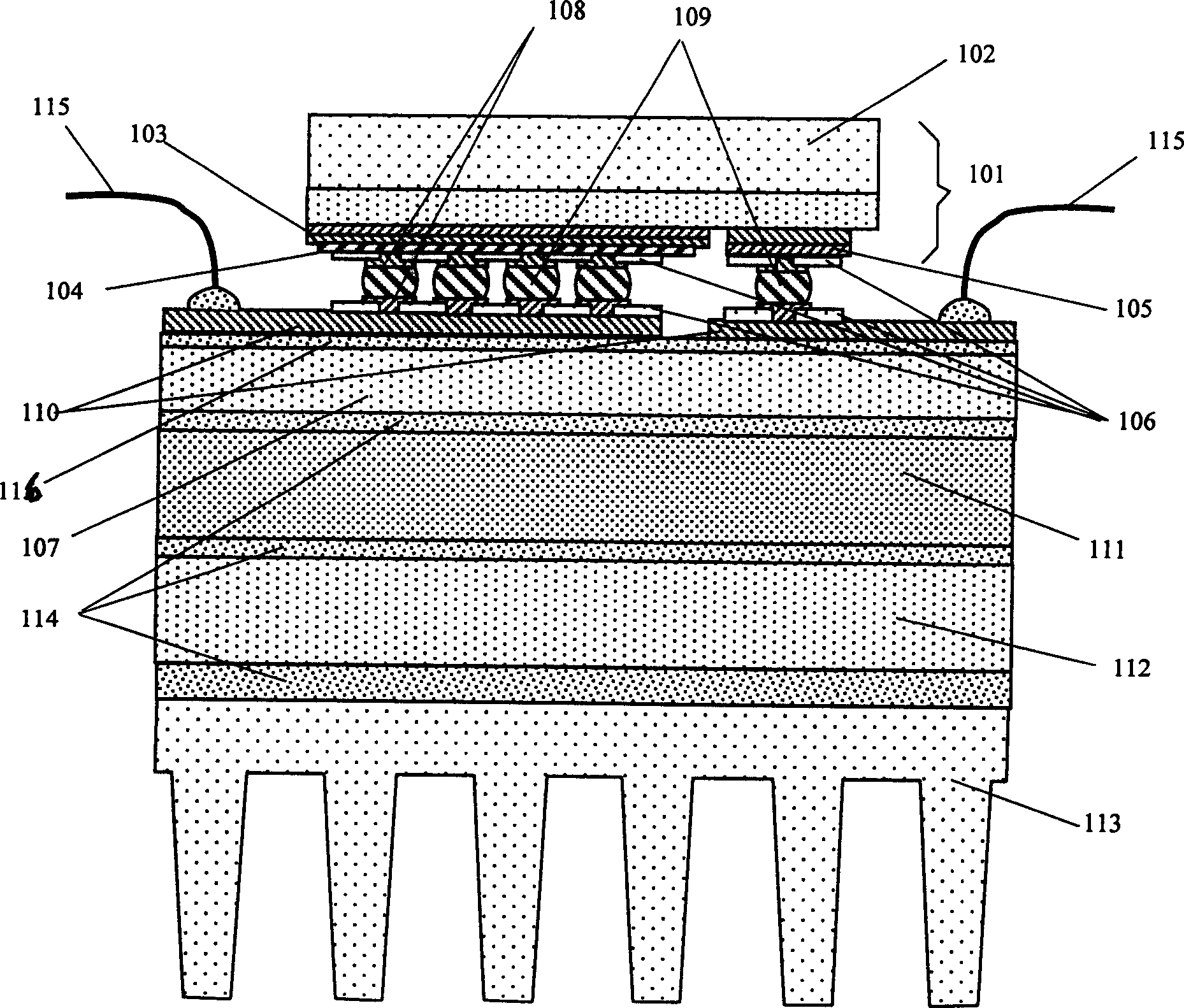

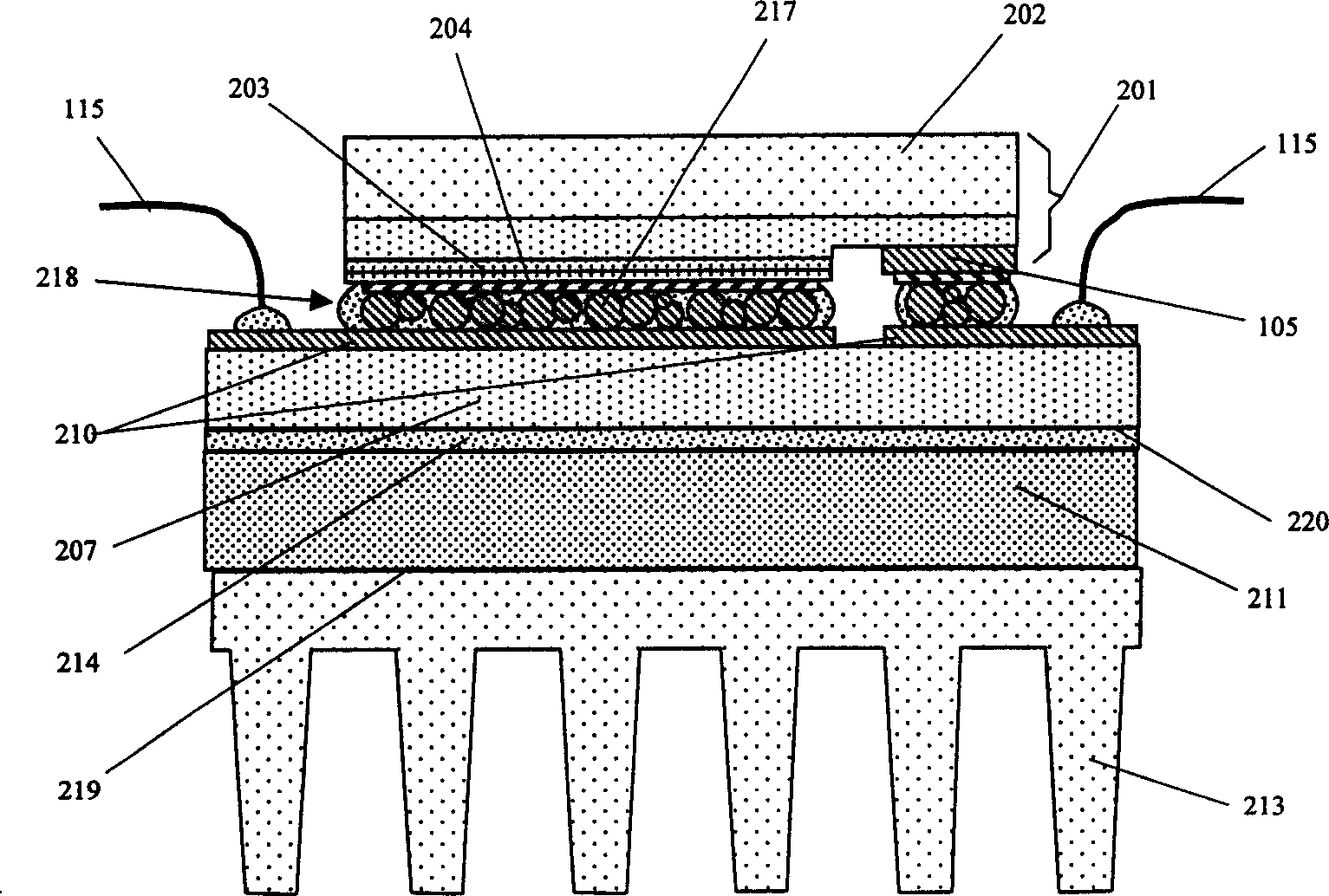

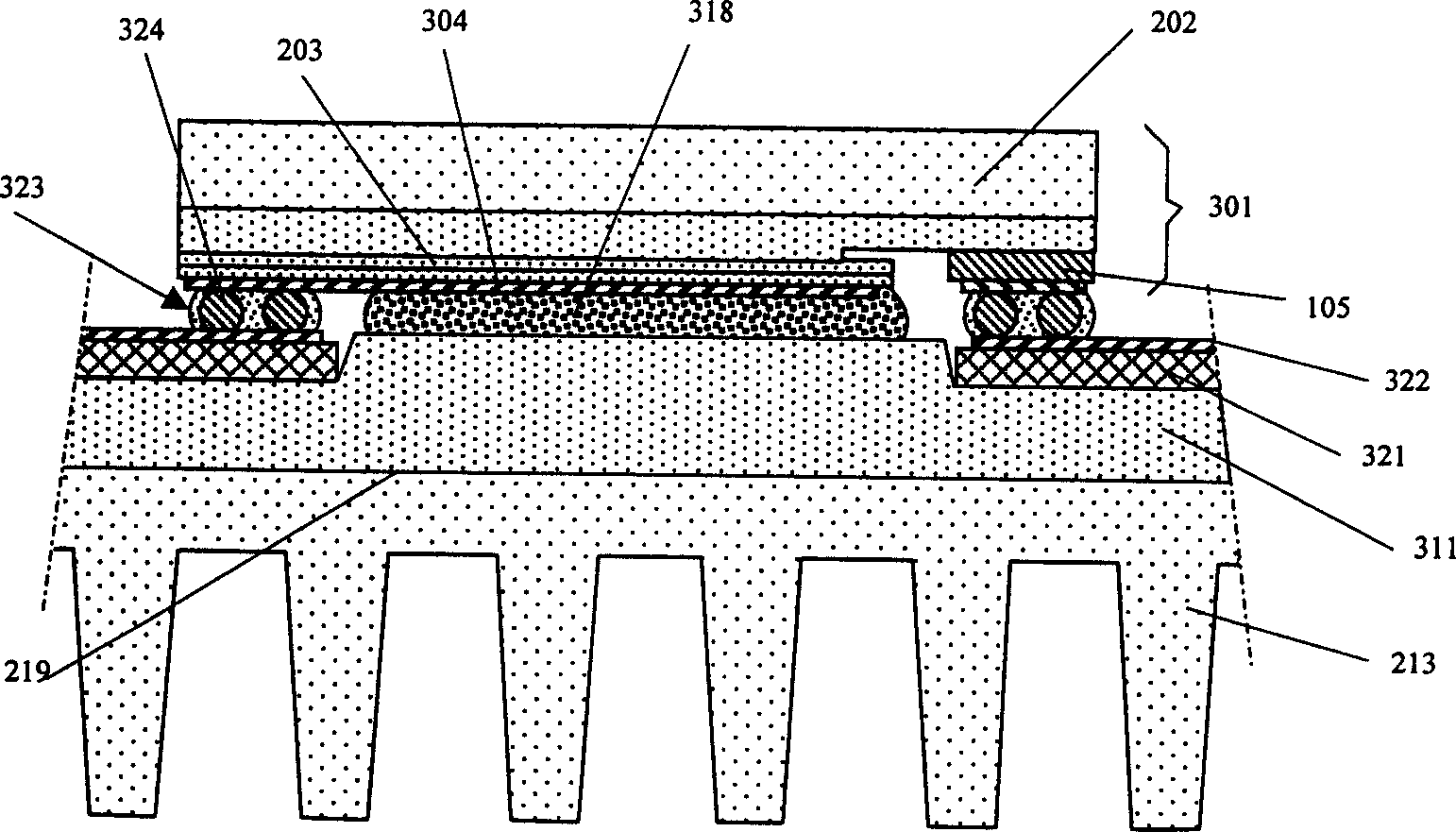

[0024] The present invention mainly includes at least one light-emitting diode chip, and the light-reflecting metal electrode on the outer surface of the p-n junction of the chip is pasted on a silicon substrate with a higher thermal conductivity than a silicon substrate through self-localized solder mixed with small silver beads or small gold beads. On the diamond substrate; the self-localized solder mixed with small silver beads or small gold beads is adsorbed by small silver beads or small gold beads when the solder melts and will not flow away to cause electrode short circuit, that is, it can be soldered without a dielectric layer Self-localized, while its thickness can be controlled by the diameter of small silver beads or small gold beads, its thickness can be very thin, such as less than 0.04mm, and the contact area with the chip can be very large, such as greater than 30% of the chip area; the diamond substrate The side facing the chip has a solderable circuit conductiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com