Open-mouthed bait for raising aquatic fry and its production process

A technology of opening bait and production method, which is applied in the field of feed, can solve problems such as indigestion, affecting health, and high hatching rate, and achieve the effect of low cost and enhancing immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

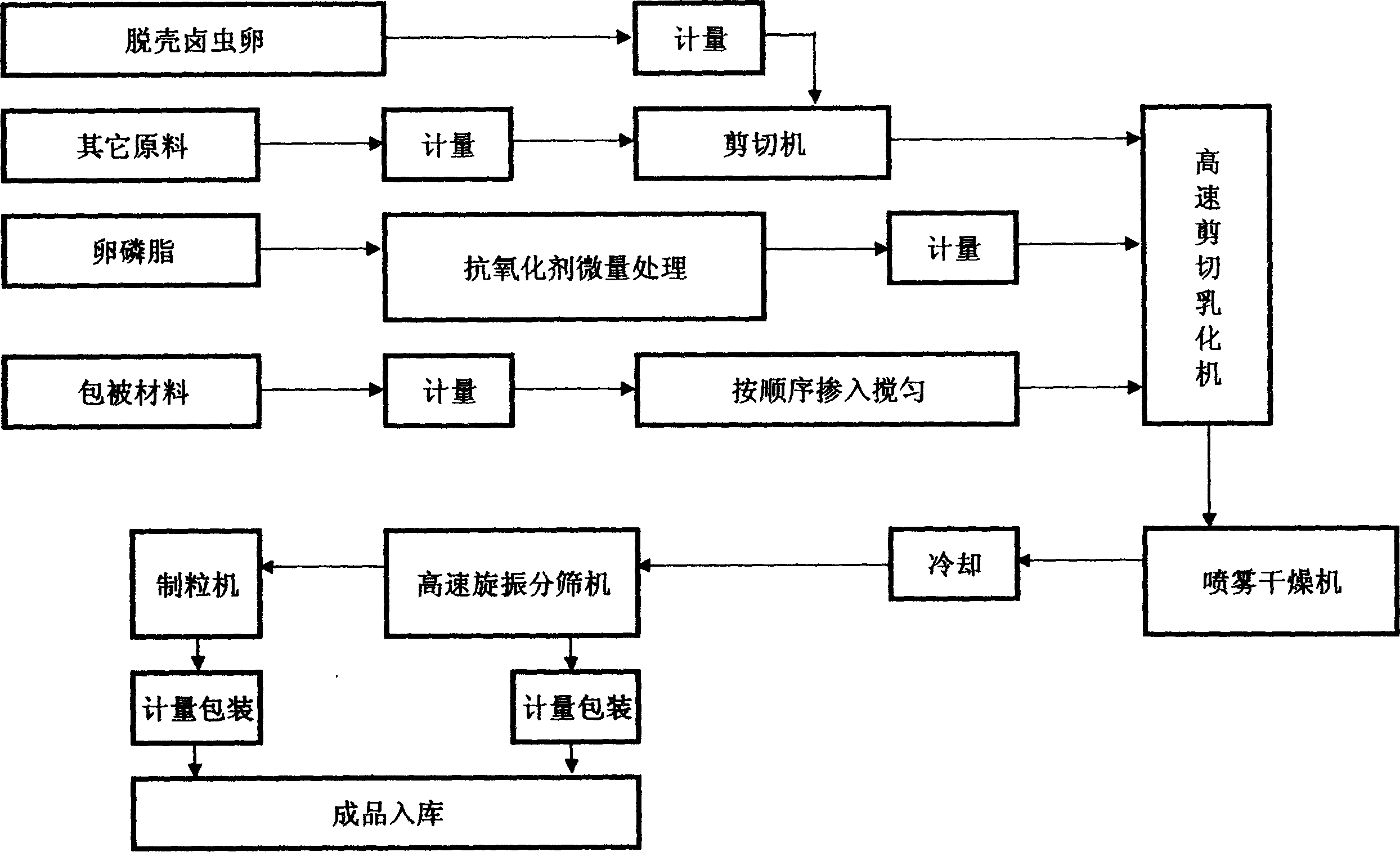

Method used

Image

Examples

Embodiment 1

[0030] a. After sterilizing and rinsing 65kg of shelled artemia eggs, they are cut by a high-speed shear and crushed to a particle size of about 50 μm for later use;

[0031] b. Grind 8kg of fishmeal and 5kg of plant protease to 50μm respectively, and set aside;

[0032] c. After 5kg of seaweed colloid is measured, it is dissolved in 20kg of 40°C hot water and stirred evenly for later use;

[0033] d. After measuring 3kg of gelatin, dissolve it in 10kg of 50°C hot water and stir well for later use;

[0034] e. After measuring 3kg of donkey-hide gelatin, dissolve it in 10kg of 50℃ hot water and stir well for later use;

[0035] f. 6kg of lecithin is used for later use, and 5kg of highly unsaturated fatty acid is measured and added with 10g of antioxidant for later use;

[0036] g. After mixing the spare materials in the above-mentioned steps a, b, c, d, e, and f, they are sheared and emulsified into a homogeneous liquid state by a high-speed shear emulsifier, and then pumped ...

Embodiment 2

[0039] a. After sterilizing and rinsing 70kg of shelled artemia eggs, they are cut by a high-speed shear and crushed to a particle size of about 50 μm for later use;

[0040] b. Grind 5kg of fish meal and 5kg of plant protease to 80μm respectively, and set aside;

[0041] c. After 5kg of seaweed colloid is measured, it is dissolved in 20kg of hot water at 38°C and stirred evenly for later use;

[0042] d. After measuring 3kg of gelatin, dissolve it in 10kg of hot water at 45°C and stir evenly for later use;

[0043] e. After measuring 2kg of donkey-hide gelatin, dissolve it in 10kg of hot water at 50°C and stir evenly for later use;

[0044] f. Measure 3kg of lecithin for standby, 5kg of premix for standby, 2kg of highly unsaturated fatty acid and add 6g of antioxidant treatment for standby;

[0045] g. After mixing the spare materials in the above-mentioned steps a, b, c, d, e, and f, they are sheared and emulsified into a homogeneous liquid state by a high-speed shear emul...

Embodiment 3

[0048] a. After sterilizing and rinsing 75kg of shelled Artemia eggs, cut them with a high-speed shear and crush them to a particle size of about 50 μm for later use;

[0049] b. Grind 5kg of fishmeal and 5kg of plant protease to 50μm respectively, and set aside;

[0050] c. After 5kg of seaweed colloid is measured, it is dissolved in 20kg of hot water at 35°C and stirred evenly for later use;

[0051] d. After measuring 2kg of gelatin, dissolve it in 10kg of hot water at 48°C and stir evenly for later use;

[0052] e. After measuring 3kg donkey-hide gelatin, dissolve it in 10kg hot water at 45°C and stir well for later use;

[0053] f. Measure 3kg of lecithin for standby, 2kg of highly unsaturated fatty acid and add 10g of antioxidant treatment for standby;

[0054]g. After mixing the spare materials in the above-mentioned steps a, b, c, d, e, and f, they are sheared and emulsified into a homogeneous liquid state by a high-speed shear emulsifier, and then pumped into a spra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com