Nano level light calcium carbonate producing process and apparatus

A light calcium carbonate, production equipment technology, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of unstable product batch quality, excessive particle diameter, uneven particle size, etc., achieve small footprint and improve absorption Rate and utilization, effect of small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

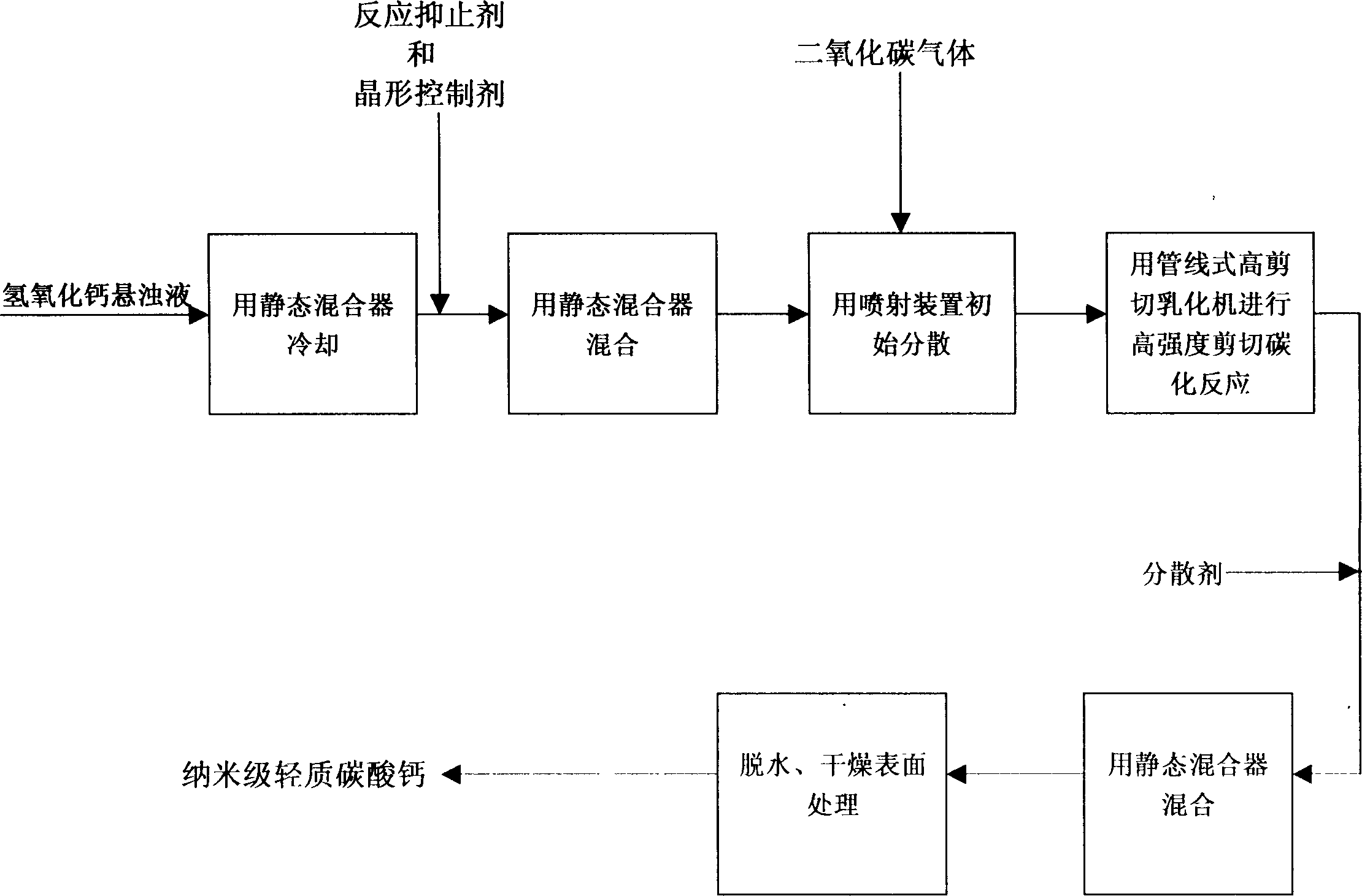

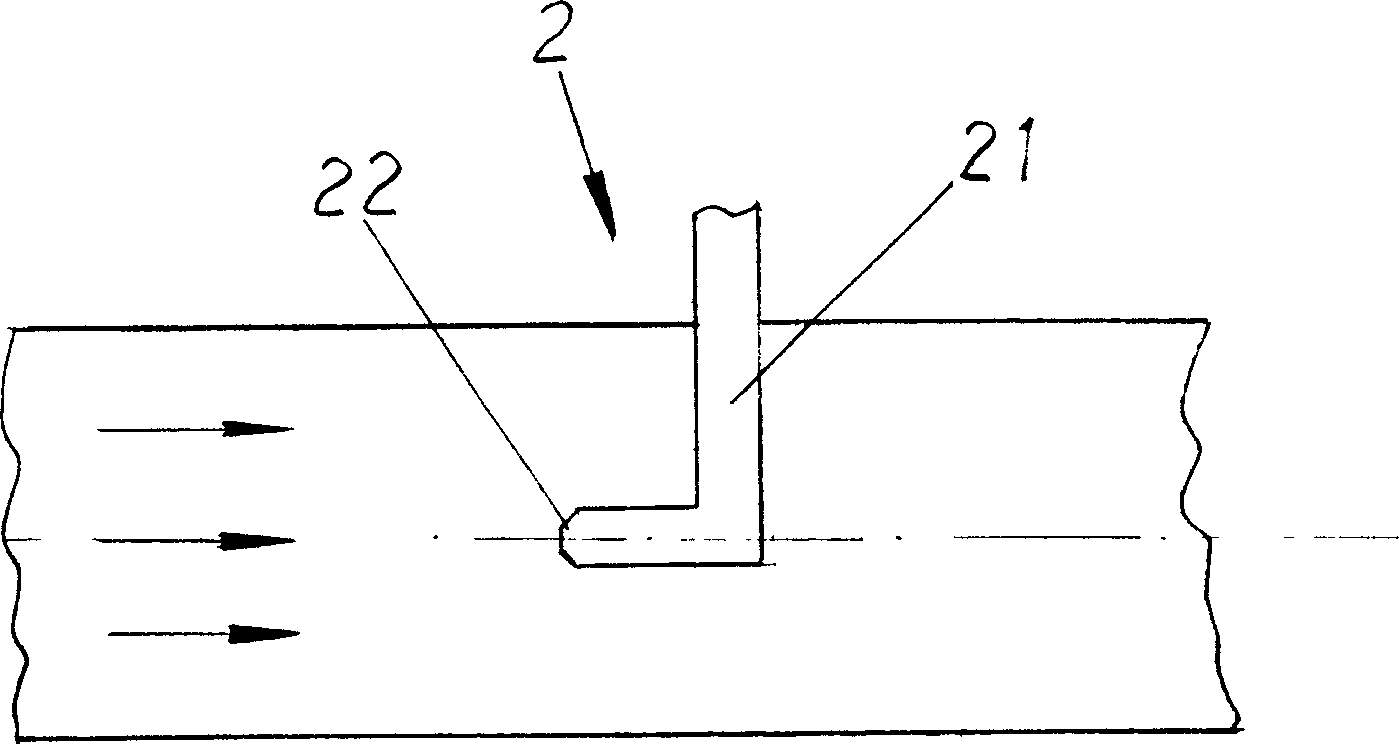

[0018] see figure 1 As shown, the present invention first utilizes a static mixer with good heat transfer effect to cool the calcium hydroxide suspension from the digestion process, and lower its temperature from 50 to 80°C to about 30°C. When the cooled calcium hydroxide suspension flows into the next static mixer, an appropriate amount of crystal form control agent and reaction inhibitor are added, and uniformly mixed in the static mixer. Import carbon dioxide gas after the above-mentioned mixed calcium hydroxide suspension flows out of the static mixer; in order to make carbon dioxide gas can be dispersed in the calcium hydroxide suspension mixed with crystal form control agent and reaction inhibition, can be provided with Air pipe 21 and spraying device 2 of spray head 22 groups (referring to image 3 ) for initial dispersion. The air delivery pipe 21 of this injection device 2 is inserted into the infusion pipeline and bent forward 90°, so that the injection head 22 wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com