Catalytic alcohol acid esterizing method

A technology for catalyzing alkyd esters and catalysts, which is applied in chemical instruments and methods, preparation of carboxylic acid esters, catalysts for physical/chemical processes, etc., and can solve the problems of environmental friendliness, large usage of ionic liquids, poor stability of ionic liquids, etc. problem, to achieve the effect of stable properties, simple synthesis method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

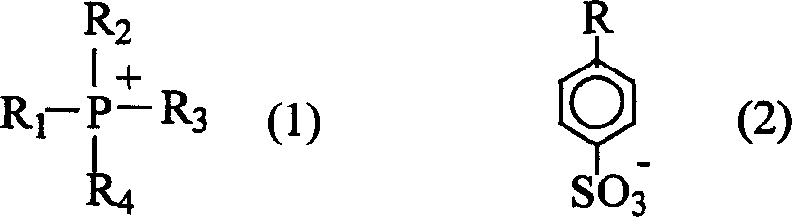

[0014] Embodiment one: 0.02 mole ionic liquid [P 666,14 LABS] and 0.25 mole of acetic acid and 0.25 mole of n-butanol are put into a reaction flask, stirred, heated, and controlled at a temperature of 100-130° C. for 2 hours, the reaction is left standing, and the esterification product n-butyl acetate is separated by liquid separation. The conversion was 94% and the selectivity was 99%. The ionic liquid in the lower layer is simply distilled to remove water and then recycled. [P 666,14 LABS] name is: trihexyl (tetradecyl) phosphonium dodecylbenzenesulfonates molecular formula is:

[0015]

Embodiment 2

[0016] Embodiment two: 0.04 mole ionic liquid [P 666,14 LABS] and 0.25 mole of acetic acid and 0.25 mole of n-butanol are put into a reaction flask, stirred, heated, and controlled at a temperature of 100-130° C. for 2 hours, the reaction is left standing, and the esterification product n-butyl acetate is separated by liquid separation. The conversion was 97% and the selectivity was 99%. The ionic liquid in the lower layer is simply distilled to remove water and then recycled. [P 666,14 LABS] name is: trihexyl (tetradecyl) phosphonium dodecylbenzenesulfonates molecular formula is:

[0017]

Embodiment 3

[0018] Example 3: Put 0.04 moles of ionic liquid [BmimCl], 0.25 moles of acetic acid and 0.25 moles of n-butanol into a reaction flask, stir and heat, and control the temperature at 100-130°C for 2 hours, let the reaction stand, and pass liquid separation Separate the esterification product n-butyl acetate, the conversion rate is 96%, and the selectivity is 99%. The ionic liquid in the lower layer is simply distilled to remove water and then recycled. [BmimCl] molecular formula is:

[0019]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com