Method for fabricating clay brick by using sludge

A technology of clay bricks and silt, which is applied in the field of clay brick production using silt, to alleviate the contradiction between supply and demand of clay, eliminate social conflicts, and reduce the land waste area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

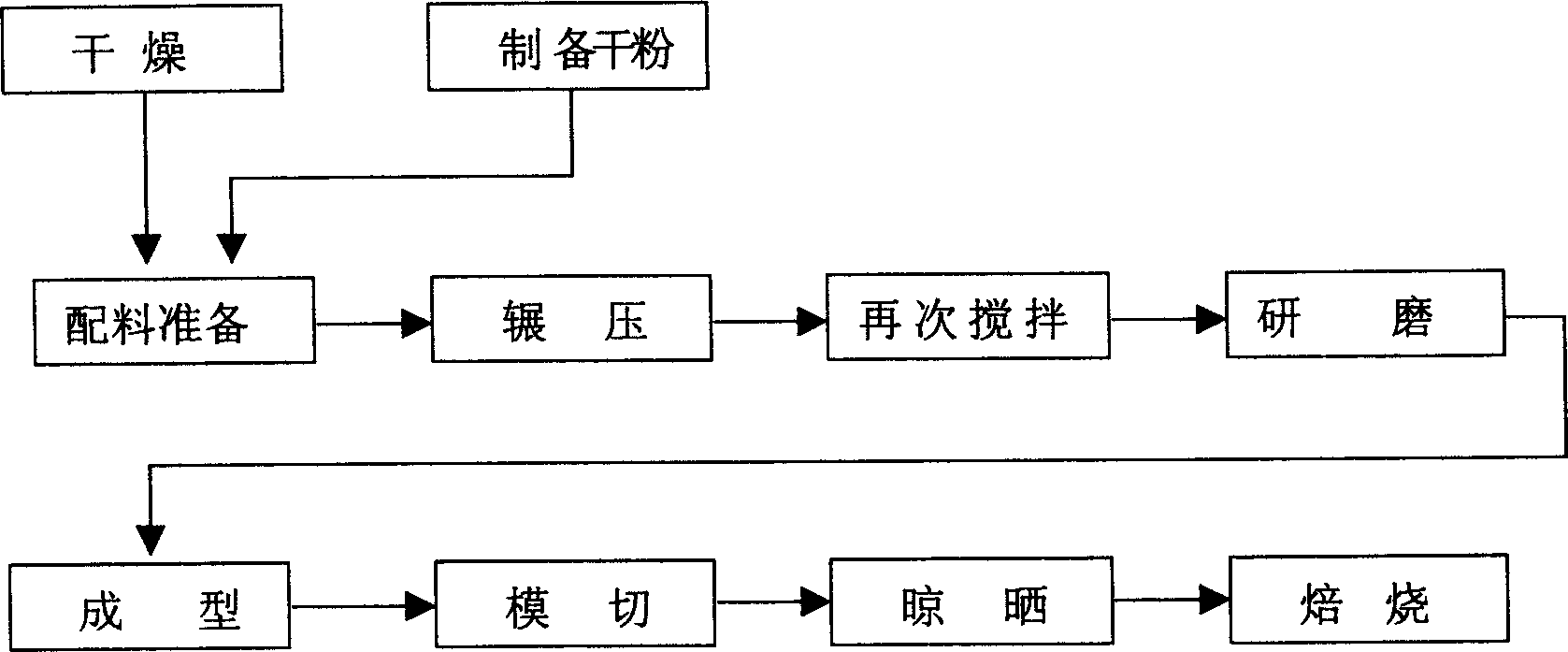

Image

Examples

Embodiment Construction

[0016] 1. Drying: Send the sludge to the conveyor belt in the drying room. The temperature of the drying room is 70-120°C to dry the material so that the moisture content of the material is less than 30%. This process is mainly used to treat some sludge with relatively high water content. When the water content of the sludge is lower than 30%, it can be directly mixed with other raw materials without drying. When drying, the evenly spread silt is transported to the conveyor belt in the drying room. The conveyor belt passes through a channel composed of 8 heating units equipped with air heating and circulation systems. Each channel has two dehumidification systems, and the sludge slowly When passing through, the hot air passes through from top to bottom or from bottom to top, and the moisture is discharged from the moisture outlet, which can greatly reduce the moisture content of the sludge after drying. The heat source used can be coal-fired or electric hot air stove, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com