Modified method for producing acetic acid through carbonylation, and equipment

A technology of carbonylation and acetic acid, applied in carbon monoxide reaction to prepare carboxylic acid, organic chemistry, etc., can solve the problems of decanter liquid phase stratification, no improvement method for carbonylation reaction system, and reduction of gas phase content in flasher, etc.

Inactive Publication Date: 2005-01-12

SHANGHAI WUJING CHEM

View PDF2 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This patent still uses the method of flashing the product to take away the heat. This method of taking away the heat of the flashing product ignores that when the moisture in the catalyst system is reduced to a certain extent when the patent adds a large amount of inorganic iodide, after the product is flashed Unfavorable effects produced in: (1) inorganic iodide is a kind of non-volatile substance, in the process of cyclic flash cooling, this reflects that a kind of heat carrier heats the reaction solution; (2) because the latent heat of evaporation of water is About 5 times that of methyl acetate, acetic acid, and methyl iodide, that is to say, for every 1 part of water that evaporates, 5 parts of other organic matter will be evaporated. When the reaction liquid enters the flash evaporator, the heat absorption decreases when each unit of flash steam is produced by flash evaporation.

The result of this adverse effect is that when the water content of the catalyst system is reduced, to remove the heat generated by the reaction in the reactor and maintain stable reaction conditions, the flasher needs to flash out the gas phase substance mass than the reaction system when the water content is high. The amount of gas phase material produced by flash distillation is greatly increased, which causes a bottleneck in the rectification area and makes the liquid phase separation in the decanter more difficult

In the subsequent patents, no improved method for the carbonylation reaction system was proposed.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0022] Referring to Table 1 and Table 2, experiments 2 to 5 are four examples of the present invention.

[0023] experiment

[0024] experiment

[0025] *STY unit: mol / s.m 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

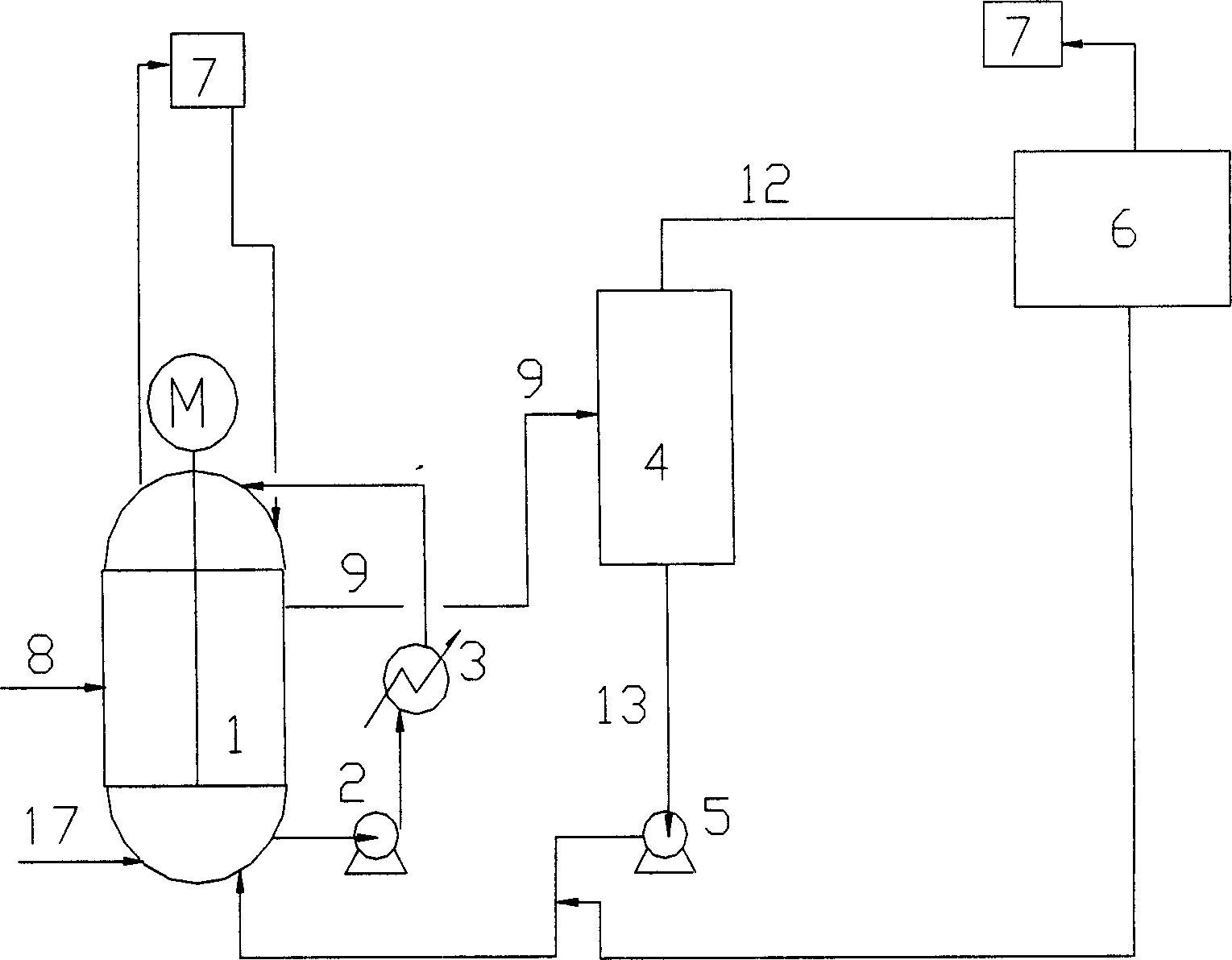

This invention relates to carbonylation prodn. of acetic acid with an additional forced cooling reactor between reactor and flash column, under pressure of 20-40 bar and temp. of 170 deg.C to 220 deg.C, and controlling feeding ratio of flash liquid to methanol=7-20. So, now the prodn. needes no removing heat by flash column. And rectifying still is not the neck of said prodn, and it can keep stable rhodium catalyst.

Description

1. Technical field: [0001] The present invention relates to a kind of production method of acetic acid and its device, in particular to an improved method for producing acetic acid by carbonylation of methanol and carbon monoxide, and a device using the method. 2. Background technology: [0002] In the 1970s, Pricker proposed a carbonylation method with carbon monoxide and methanol in US Patent No. 3,769,329. Use rhodium catalyst to add methyl iodide, methyl acetate, water and use acetic acid as a solvent to form a reaction solution. Carbon monoxide and methanol are carbonylated in the reaction solution to generate acetic acid. The crude acetic acid of the component is obtained by the rectification method well known in the chemical industry to obtain the pure product acetic acid, and this method is finally industrialized all over the world. In the 1980s, Celanese Brad L. Smith and others improved the Pricker method. Propose in patent CN85101460, add inorganic iodine salt i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07C51/12C07C53/08

Inventor 陈大胜刘艳曹智龙吴文晶姚长根

Owner SHANGHAI WUJING CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com