Cushion body and foam resin particles for filling cushion body

A foamed resin and buffer technology, applied in the field of buffers, can solve the problems of being woken up, unpleasant, noise, etc., and achieve the effect of increasing the allowable range and improving the touch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

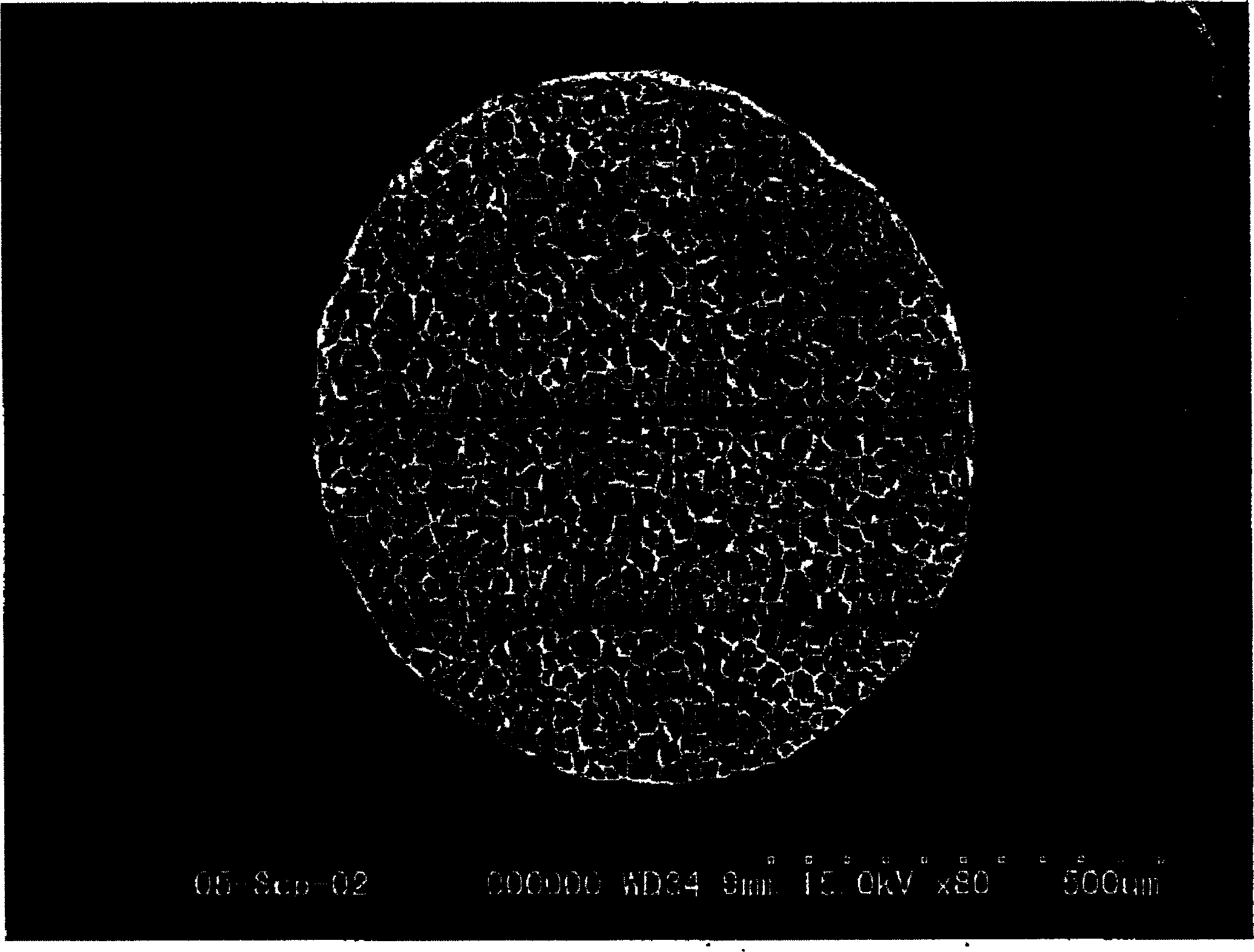

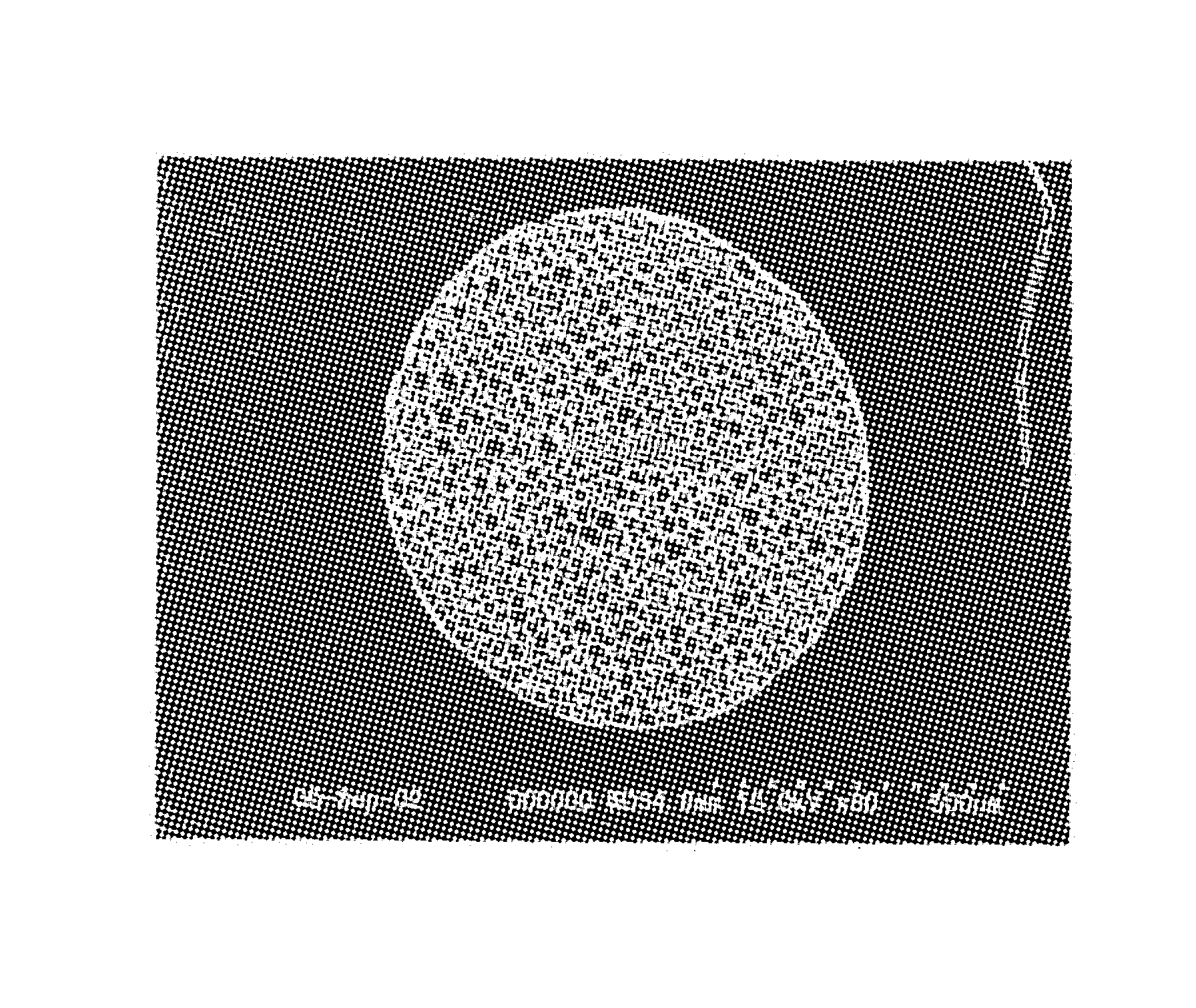

Image

Examples

Embodiment 1

[0125] In the autoclave of 100L, add 120g tricalcium phosphate (product of Taiping Chemical Company, trade name is tricalcium phosphate), 0.24g sodium bisulfite and 0.24g potassium persulfate, then add 133g benzyl peroxide in this mixed solution Acyl (75% purity, product of NOF Corporation, trade name Niper BW), 28g tert-hexyl peroxyisopropyl monocarbonate (90% purity, product of NOF Corporation, trade name Perhexyl I), 40kg deionized water and 40kg of styrene monomer were dissolved and suspended by stirring to prepare a suspension.

[0126] Then, the styrene monomer was polymerized at 87° C. for 8 hours at a stirring speed of 200 rpm, and then polymerized at 125° C. for 2.5 hours. After the reaction is completed, the reaction mixture is cooled, taken out from the autoclave, centrifuged and dried to obtain styrene resin particles. The resulting styrene resin particles were sieved into particles of 0.25 to 0.355 mm.

[0127] In addition, 2000 g of water, 12 g of magnesium pyr...

Embodiment 2

[0131] Expanded resin particles were manufactured in the same manner as in Example 1, except that zinc stearate was added in an amount of 8.50 g (1.0 parts by weight). The average particle diameter, flow promoter content, local compressive load, apparent specific gravity, number of bubbles, and residual styrene monomer amount of the obtained foamed resin particles were measured, and a noise test and a touch test were performed. The foamed resin particles do not contain particles with a diameter larger than 2 mm. The results are listed in Table 1.

Embodiment 3

[0133] Expanded resin particles were manufactured in the same manner as in Example 1, except that zinc stearate was added in an amount of 15.3 g (1.8 parts by weight). The average particle diameter, flow promoter content, local compressive load, apparent specific gravity, number of bubbles, and residual styrene monomer amount of the obtained foamed resin particles were measured, and a noise test and a touch test were performed. The foamed resin particles do not contain particles with a diameter larger than 2 mm. The results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com