Interlayer connection structure and its building method

A technology of interlayer connection and conductive connection, which is applied in the direction of electrical connection formation of printed components, multi-layer circuit manufacturing, electrical components, etc. It can solve the problems of difficult uniform contact, inability to conduct conductive connection, and reinforcing fiber hindering contact, etc., to achieve uniform thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

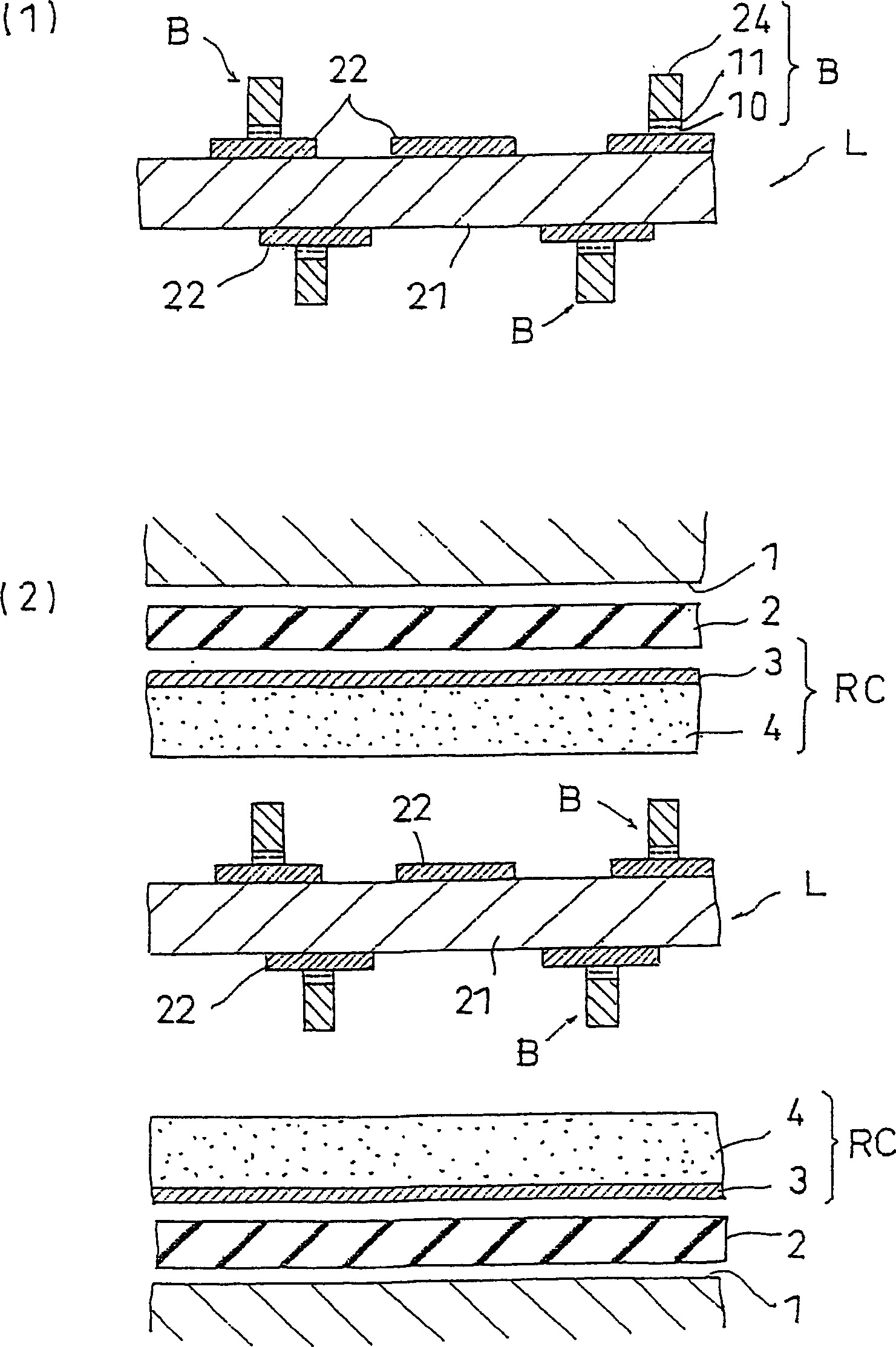

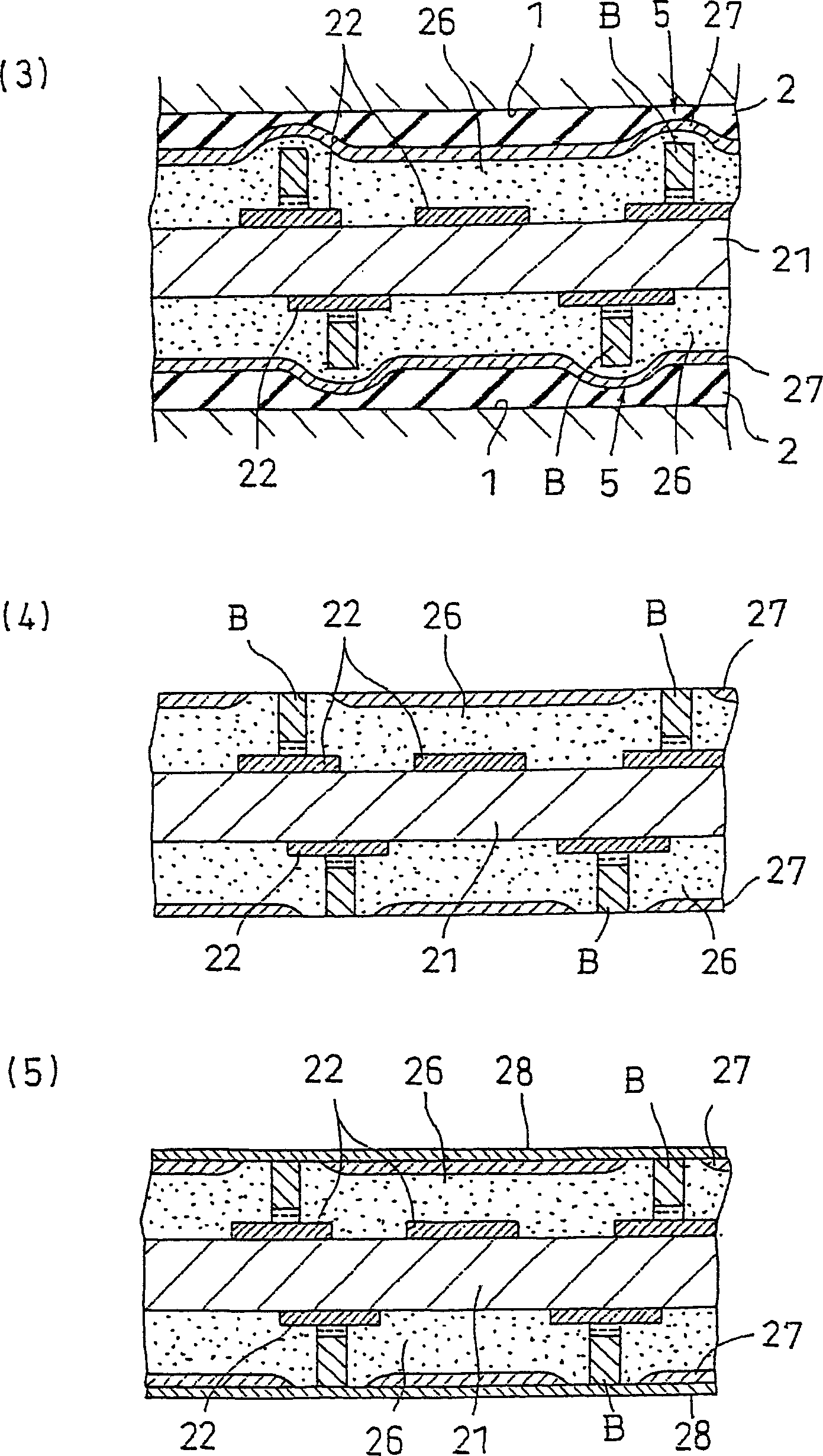

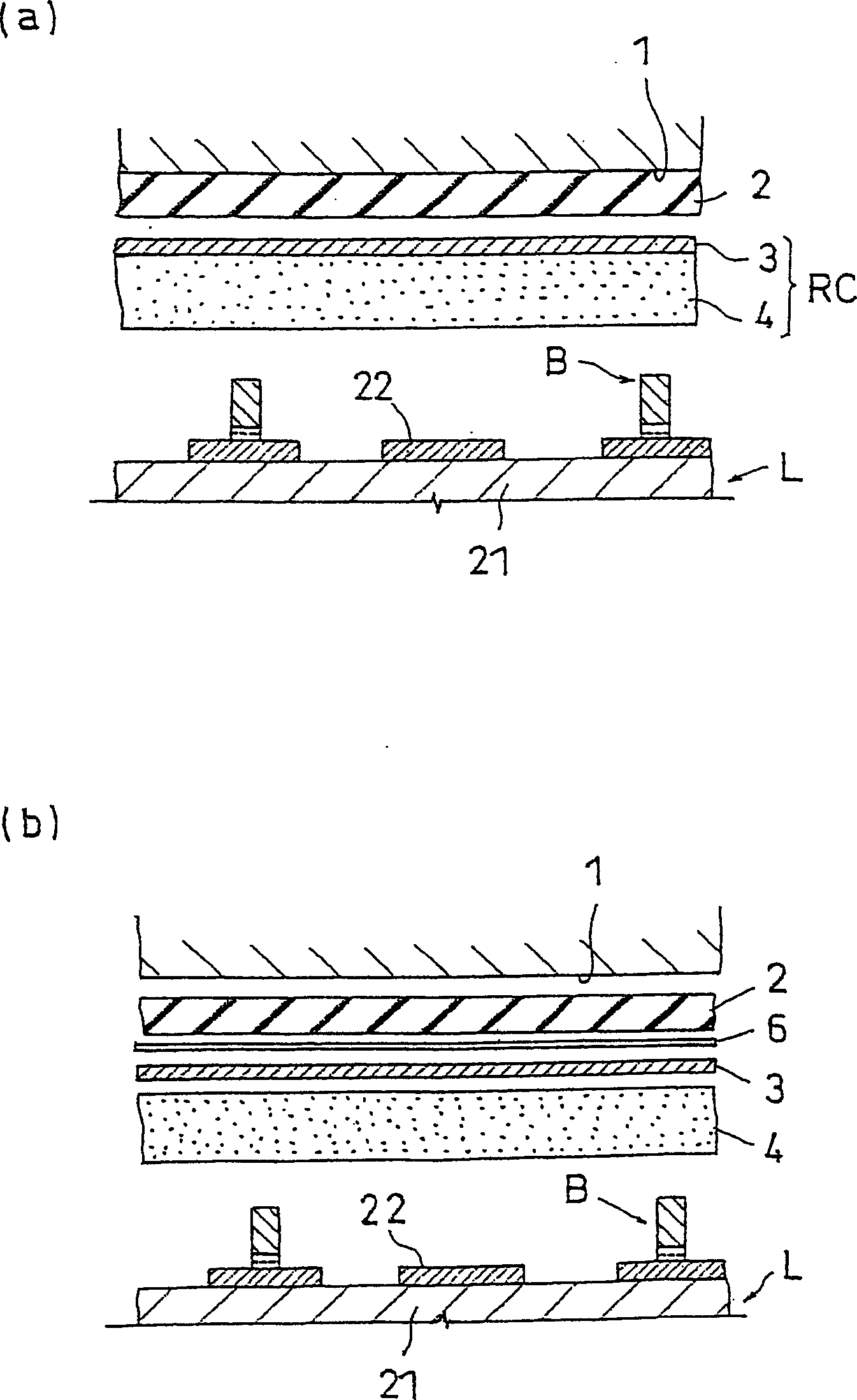

[0025] (The first method of forming an interlayer connection structure invented)

[0026] In this embodiment, it is described that the wiring layer 22 formed on both sides of the central substrate and the metal layer 27 formed on the upper layer via the insulating layer 26 are connected between layers through the interlayer connection protrusion B to form an interlayer connection structure. example of.

[0027] First, if figure 1 As shown in (1), a laminated body L is prepared in which the pattern of the wiring layer 22 is formed on both surfaces of the base material 21 and the interlayer connection protrusions B are formed on the wiring layer 22 . At this time, any method can be used for patterning the wiring layer 22, for example, a method using an etching resist, a method using a resist for pattern plating, or the like can be used. As the metal constituting the wiring layer 22, copper, nickel, tin, etc. are generally used, and copper is preferably used. As the base mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com