Full automatic negative pressure fermentation and deodorization device for organic fertilizer and production process

A technology of organic fertilizer and production process, which is applied in the field of deodorization device, automatic fermentation of organic fertilizer, production and manufacturing of organic fertilizer, and can solve the problems of sewage and odor discharge, large floor area, and long maturity time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

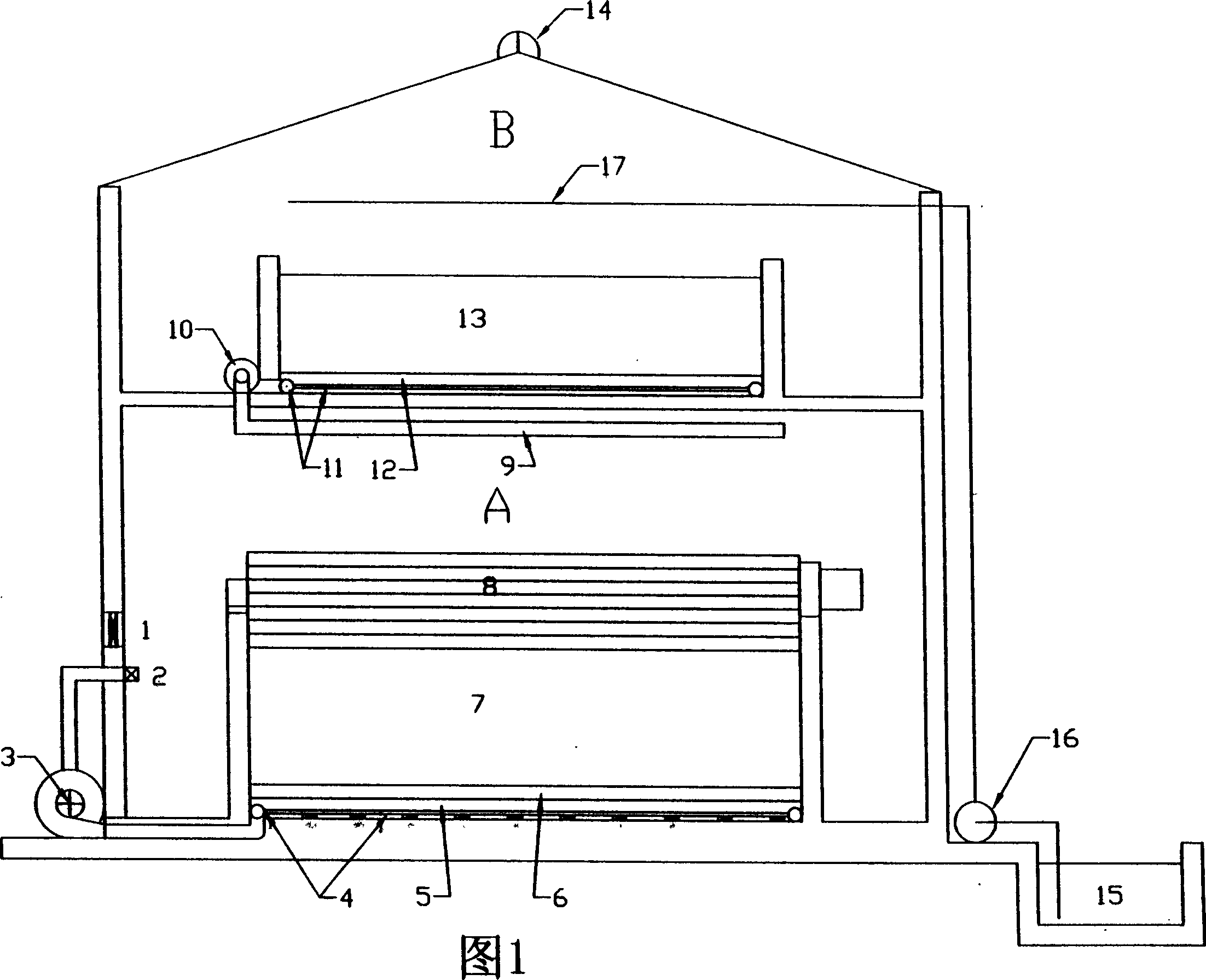

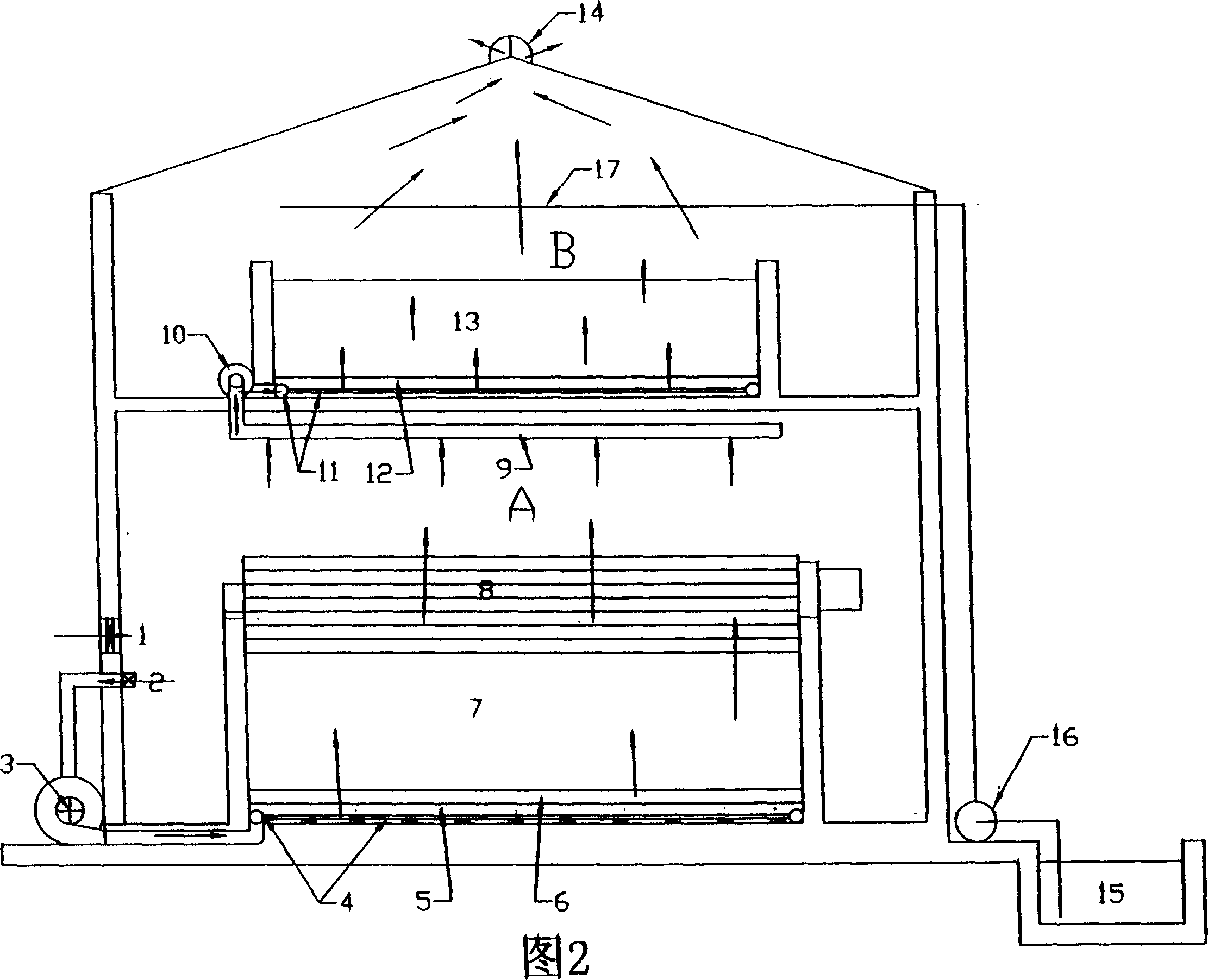

[0009] Device and technique of the present invention are further described with organic fertilizer raw material fermentation below:

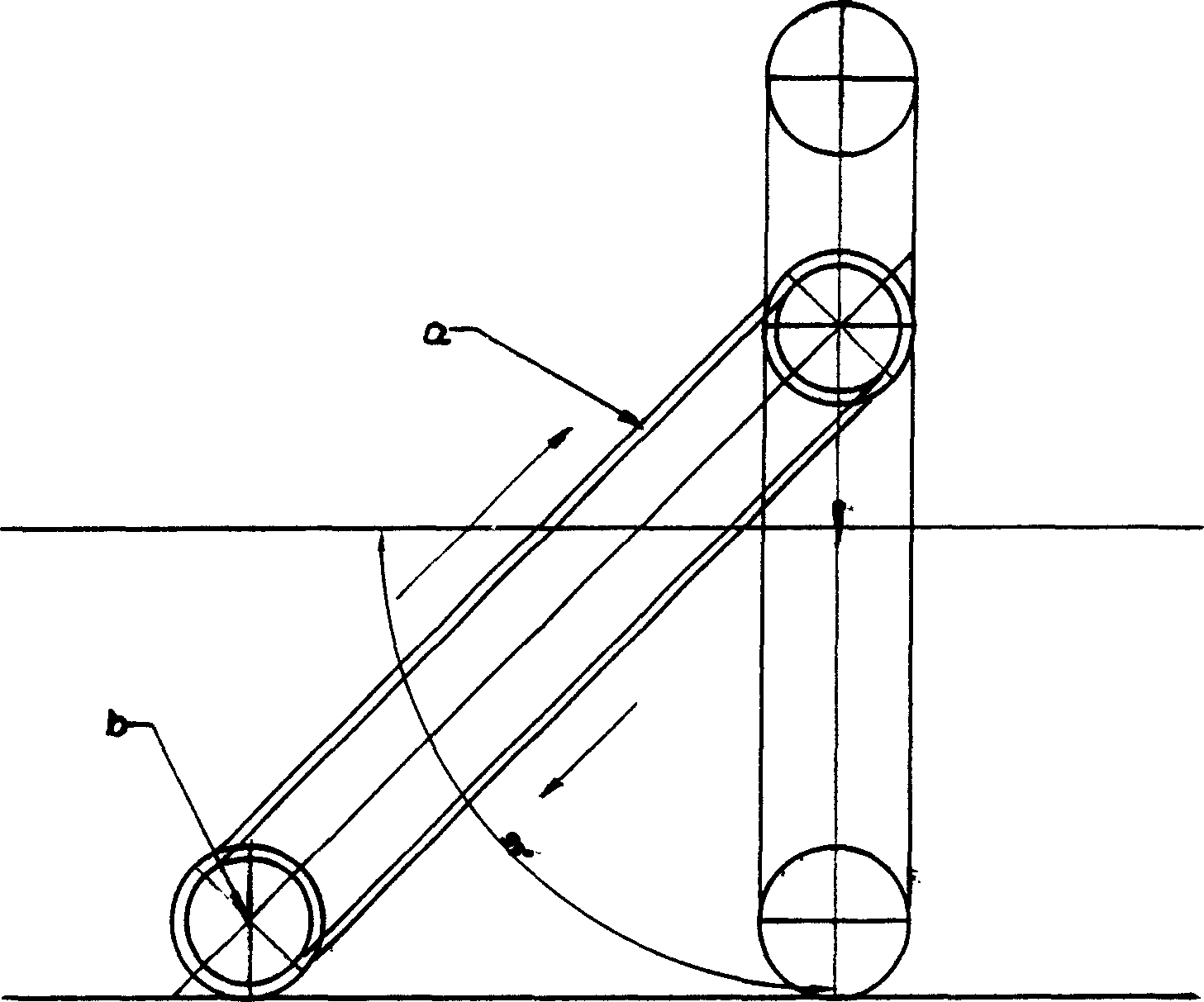

[0010] See accompanying drawing 1,2,3, adopt the compost fermentation tank (7) to be provided with on the ground in the factory building of airtight mode, the bottom layer in the compost fermentation tank (7) establishes pebble layer (5), arranges in the pebble layer (5) The air supply pipe (4), the pebble layer (5) is provided with a rice husk layer (6), the organic fertilizer raw material (7-1) is piled up on the rice husk layer (6), and the top of the compost fermentation tank (7) is provided with a turner. Stacker (8); the upper end of the plant is designed with a suction pipe (9) to connect with the exhaust fan unit (10) of the microbial filter bed deodorization chamber (B) of the peripheral equipment, and the exhaust fan unit (10) is connected with the microbial deodorization tank (13) An air supply pipe (11) is arranged in the pebble laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com