Laminated glass and its production method

A technology of laminated glass and glass, applied in chemical instruments and methods, glass/slag layered products, layered products, etc., which can solve the problems of anti-theft of laminated glass, unsatisfactory sun protection effect, unsatisfactory fire resistance, and reduced glass strength, etc. , to protect eyesight and skin, save power consumption, and prevent the spread of flames and smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

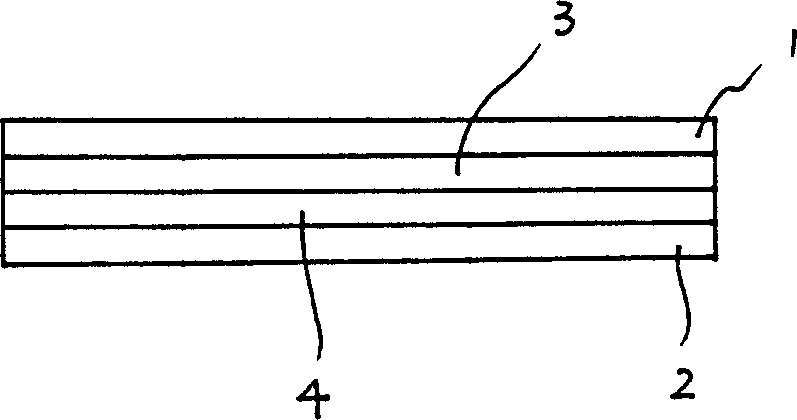

[0026] Such as figure 1 The structure shown is Embodiment 1 of the present invention, and it comprises inner and outer two layers of glass 1, 2 and interlayer film, and two layers of transparent interlayer films are sandwiched between inner and outer two layers of glass, wherein one layer of interlayer film is protective Film 3 is used to improve the performance of the laminated glass in an all-round way. The protective film is made of American Masterbao brand protective film. The performance of the laminated glass is superior, which can greatly improve the ability of the laminated glass to withstand the impact of external forces, and can even resist the shooting of a pistol, as if the glass is equipped with a layer of invisible armor, which can effectively prevent accidents and patronage from thieves, and also make the laminated glass have a Excellent fire prevention, heat insulation, heat preservation and anti-ultraviolet function; another layer of intermediate film is trans...

Embodiment 2

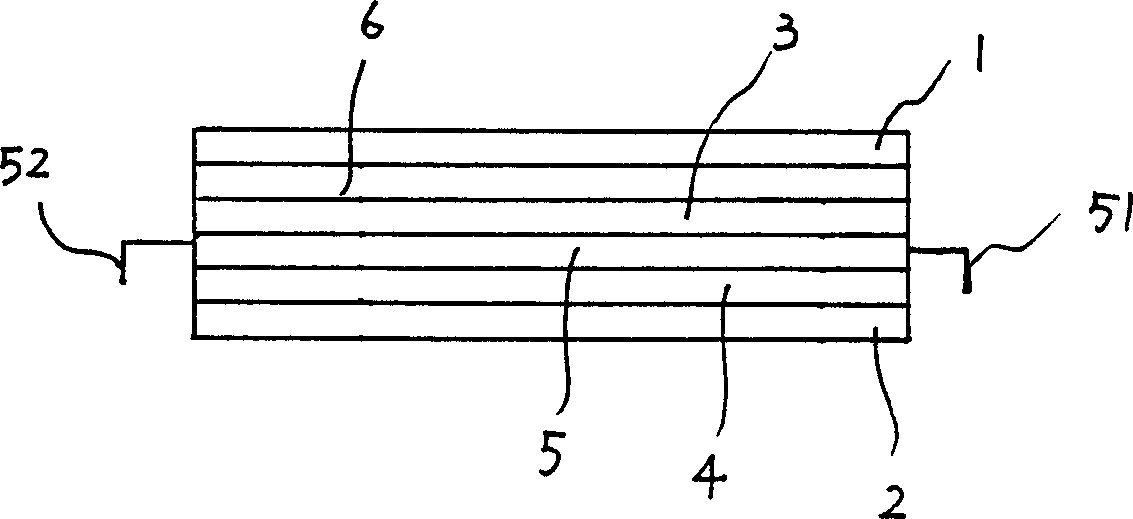

[0035] Such as figure 2 The structure shown is the second embodiment of the present invention, which is different from the first embodiment in that: there is also a light-adjusting layer 5 that can control the transparency of the glass between the interlayer films between the inner and outer layers of glass 1 and 2, The dimming layer is composed of a liquid crystal mixed with a dimming film and phosphor powder, it is located between the transparent film and the protective film, and two power cord ends 51, 52 that can form a loop are connected to the edge of the dimming layer . When the power is turned on, the light-adjusting layer 5 can become blurred within 1 second under the action of the voltage, making the laminated glass produce a frosted effect, thereby changing the perspective of the glass. After the power is cut off, the light-adjusting layer 5 returns to the transparent state. In addition, a layer of PVC transparent film 6 is added between the protective film 3 and...

Embodiment 3

[0046] The difference between this embodiment and the second embodiment is that the transparent film is PVB film, and its composition is polyvinyl butyral. Compared with PVC film, its impact resistance and UV protection effect are better.

[0047] The manufacture method of the laminated glass of the present embodiment is:

[0048] a. Clean the surface of the fireproof tempered glass with water or alcohol, and then air dry;

[0049] b. In the clean room, spread a layer of transparent PVB film on one side of the glass;

[0050] c. Spread a light-adjusting layer on the transparent PVC film;

[0051] d. Lay a layer of protective film on the dimming layer;

[0052] e. Spread a layer of PVB transparent film on the protective film;

[0053] f. Add a layer of fireproof tempered glass cleaned with water or alcohol on the PVB transparent film in step e;

[0054] g. Put the material that has completed the above steps into the lamination furnace and pressurize it, and continue heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com