Reinforced material for concrete building repairing ,repairing and reinforcing technology for concrete building

A technology for concrete construction and reinforcement materials, applied in the processing of building materials, building maintenance, construction, etc., can solve the problems of tension damage, efficiency reduction, interface separation, etc., achieve high tensile strength and fatigue strength, and reduce the number of bolt holes , sticky and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The technical constitution of the present invention will be described below with reference to the accompanying drawings according to examples.

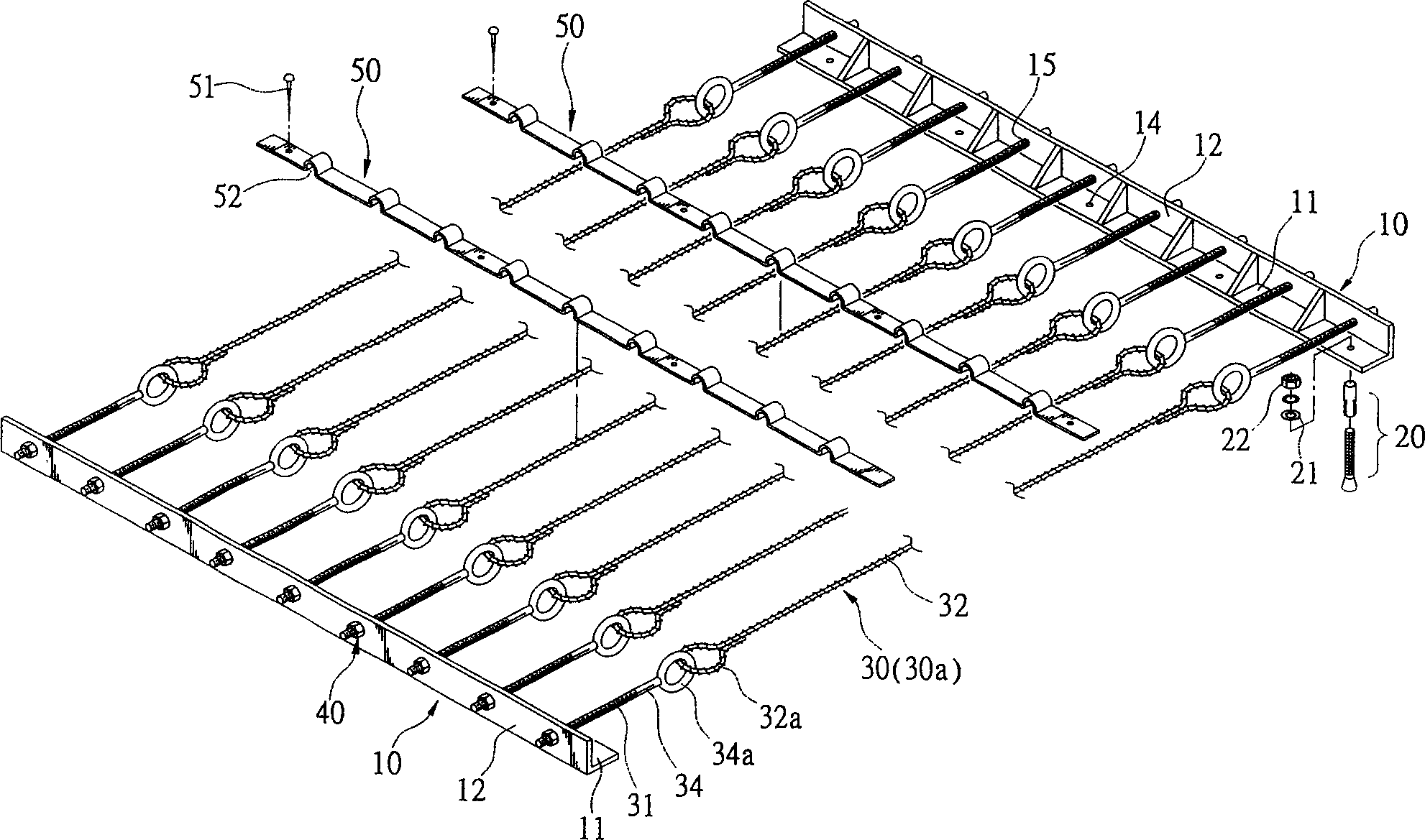

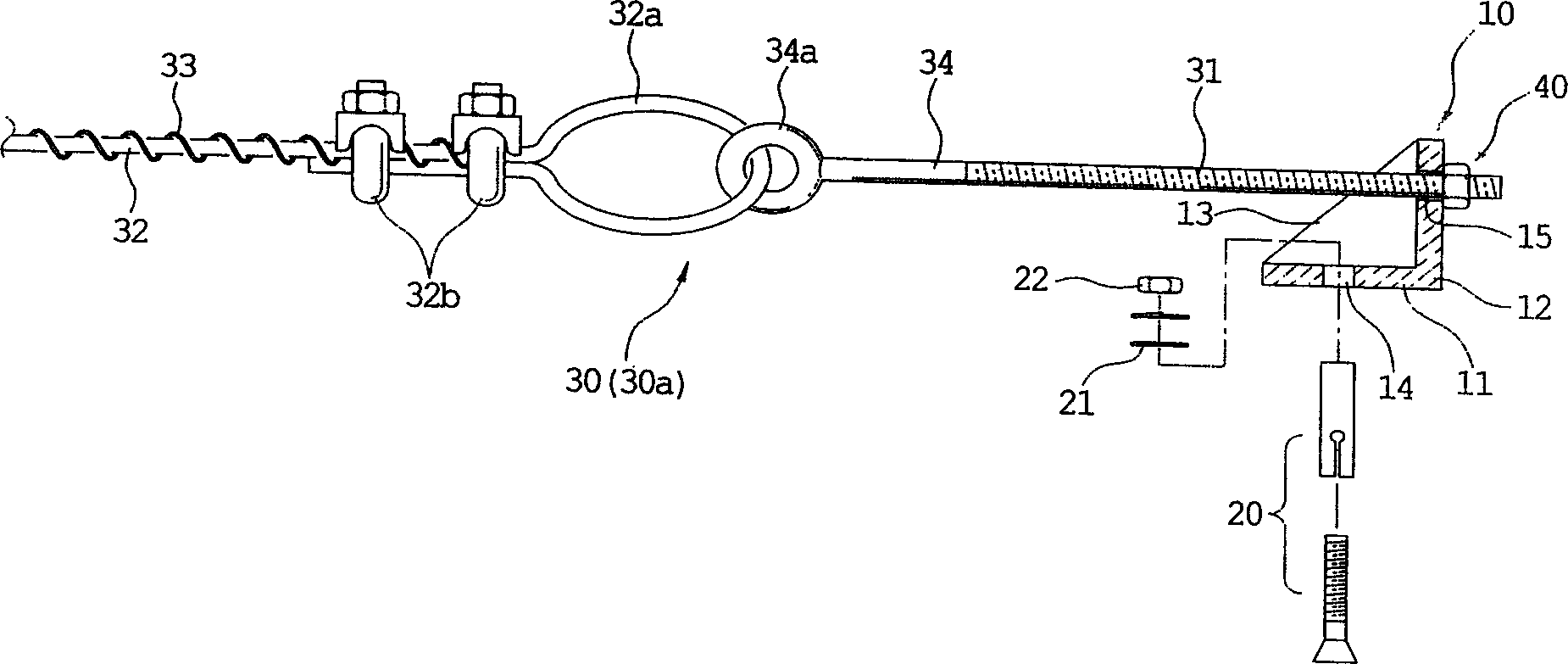

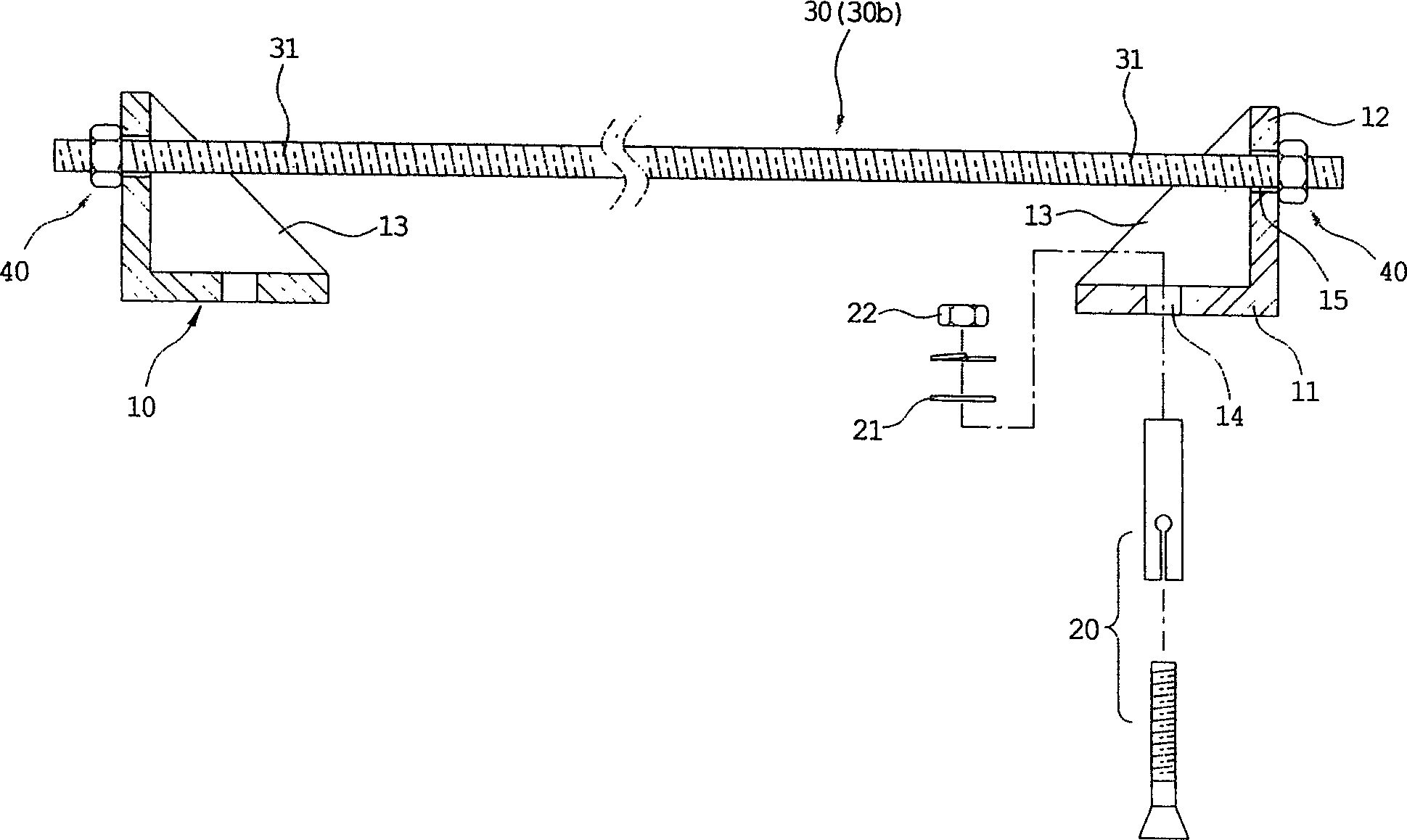

[0070] figure 1 , figure 2 Representing the reinforcement material for repairing concrete buildings and the material for fixing in Example 1 of the present invention, image 3 Reinforcing material for repairing concrete buildings of Example 2 is shown.

[0071] As shown in the figure, the reinforcing material of the present invention includes: a pair of right-angled support strips 10 opposite to each other at a predetermined distance; bolts 20 that are connected to the right-angled support strips to fix it on the surface of a concrete building; At the two ends of above-mentioned 1 pair of right-angled support belts 10, make it maintain the linear tension material 30 of balance; Be located at the outside of above-mentioned 1 pair of right-angled support belts, cooperate with the screw rod of linear tension material, the linea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com