Drier

一种烘干机、压缩机的技术,应用在烘干机领域,能够解决阻碍冷却线圈或加热线圈温度控制、难烘干、能源成本高涨等问题,达到缩短烘干时间、提高烘干性能、均匀烘干的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

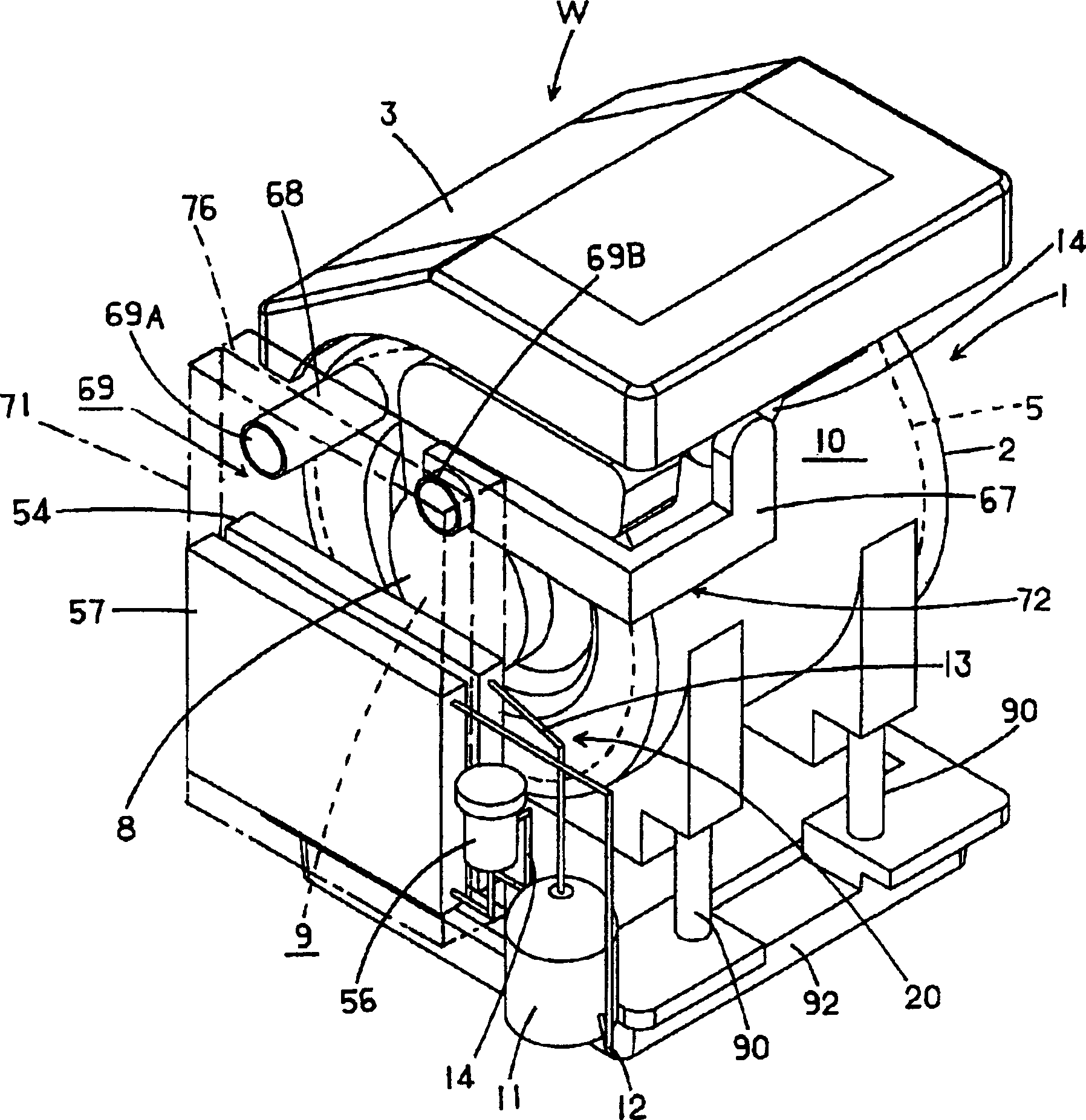

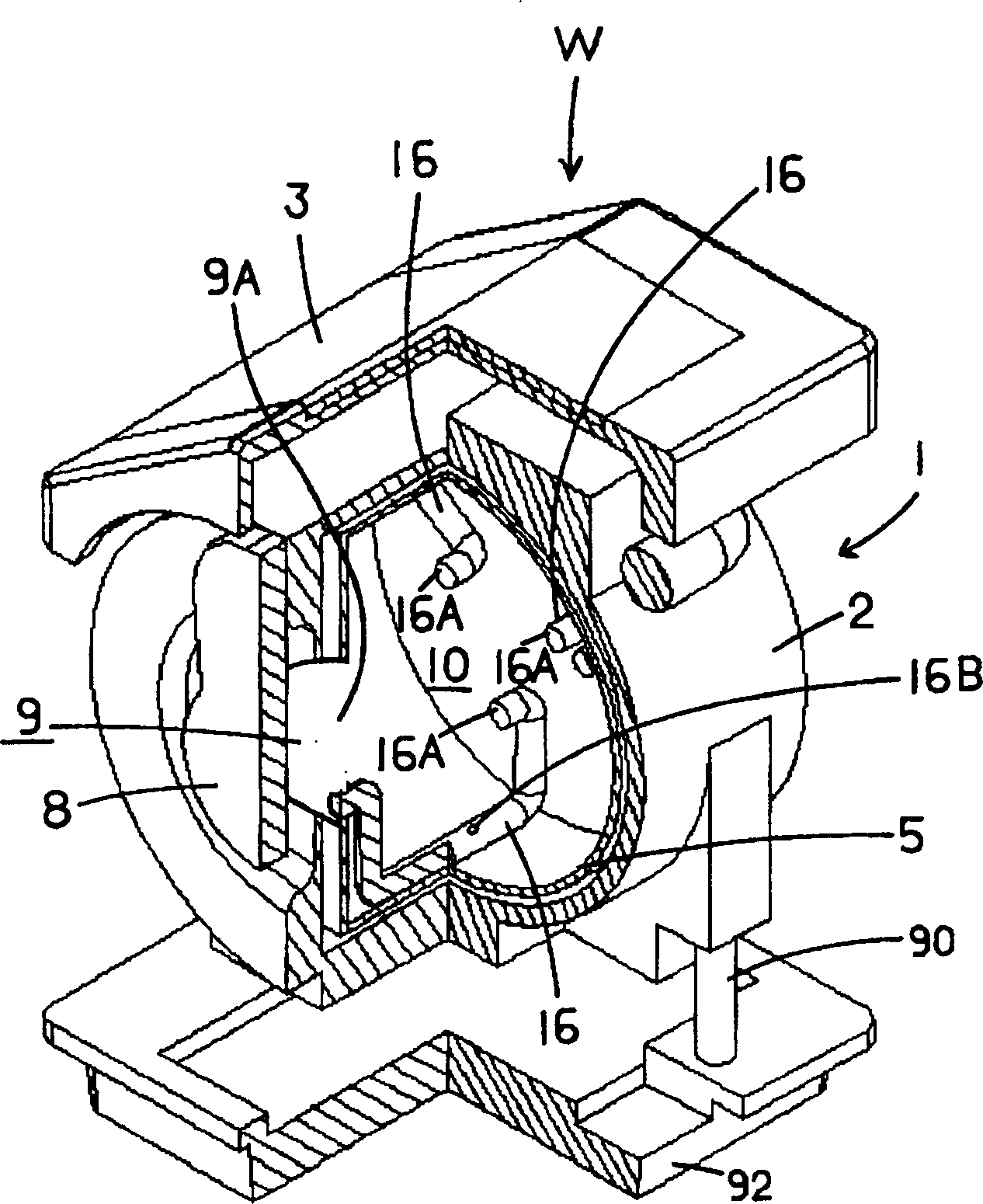

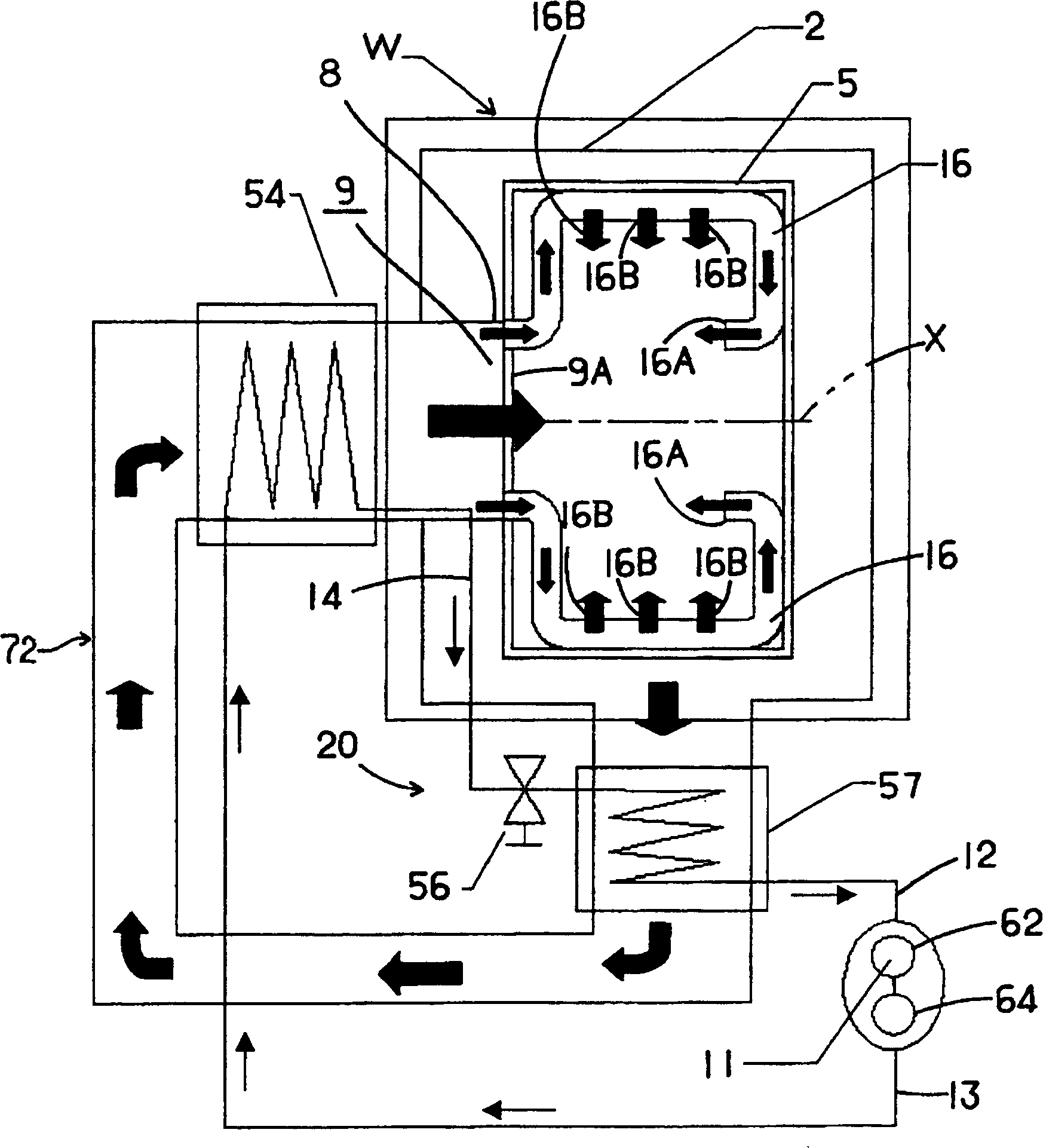

[0065] First, the first embodiment of the present invention will be described in detail with reference to the drawings. figure 1 It is a perspective view showing the internal structure of a washing and drying machine W that performs a washing operation and a drying operation after the completion of the washing operation, to which Embodiment 1 of the dryer of the present invention is applied, figure 2 Yes figure 1 Partially cut-away perspective view of image 3 It is a diagram showing the flow of the refrigerant and drying air in the washing and drying machine W. The washing and drying machine W of the first embodiment is an equipment for washing and drying laundry and other laundry (the laundry becomes the object to be dried during the drying operation). Shows the inside of the casing of the see-through main body 1) is mounted on the upper center part of the opening and closing door 3 for loading and unloading the laundry. On the side of the opening and closing door 3, the uppe...

Embodiment approach 2

[0105] The present embodiment provides a dryer that uses the dew of the evaporator to easily collect the lint floating in the drying air, and prevents clogging of the radiator or the evaporator caused by the lint beforehand. Hereinafter, the present embodiment will be described with reference to a washing and drying machine W that performs a washing operation and performs a drying operation after the completion of the washing operation. Figure 4 It is a diagram of the internal structure of the washing and drying machine W viewed diagonally from the front, Figure 5 It is a diagram of the internal structure of the washing and drying machine W viewed obliquely from behind, Figure 6 It is a circuit diagram showing the refrigerant circuit 26 and the air circulation path constituting the heat pump unit 39.

[0106] The washing and drying machine W is an equipment that washes and dries the laundry such as clothes (the laundry becomes the object to be dried during the drying operation)...

Embodiment approach 3

[0147] This embodiment provides a washing and drying machine capable of shortening the drying time of the laundry. Hereinafter, this embodiment will be described in detail with reference to the drawings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com