Tablet type large size precision diamond wire electrode cutter

A diamond wire, large-size technology, applied in the field of precision diamond wire cutting machines, can solve the problems of complex structure, inconvenient operation and adjustment, high price, etc., and achieve the effects of convenient tension adjustment, high running accuracy and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

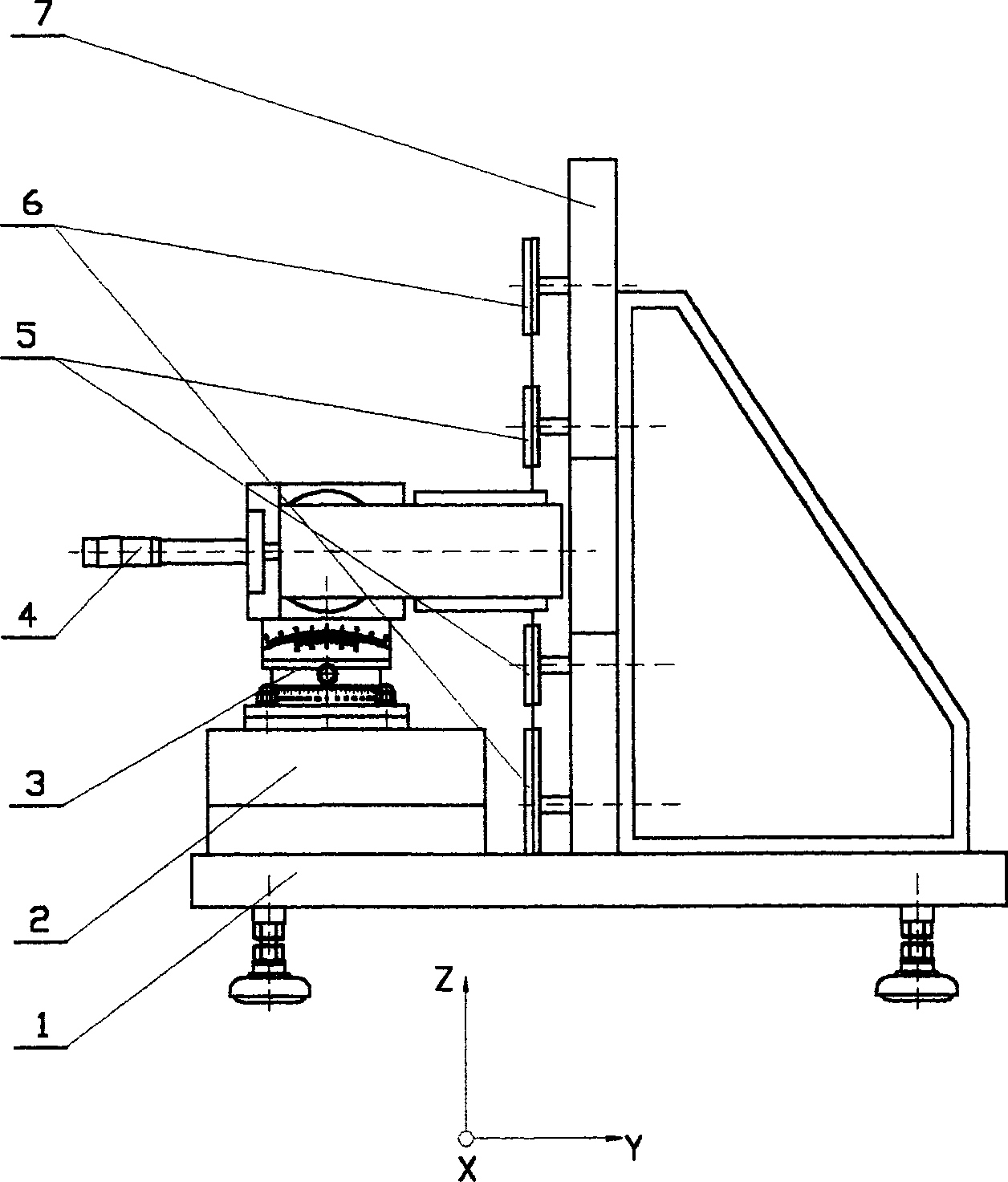

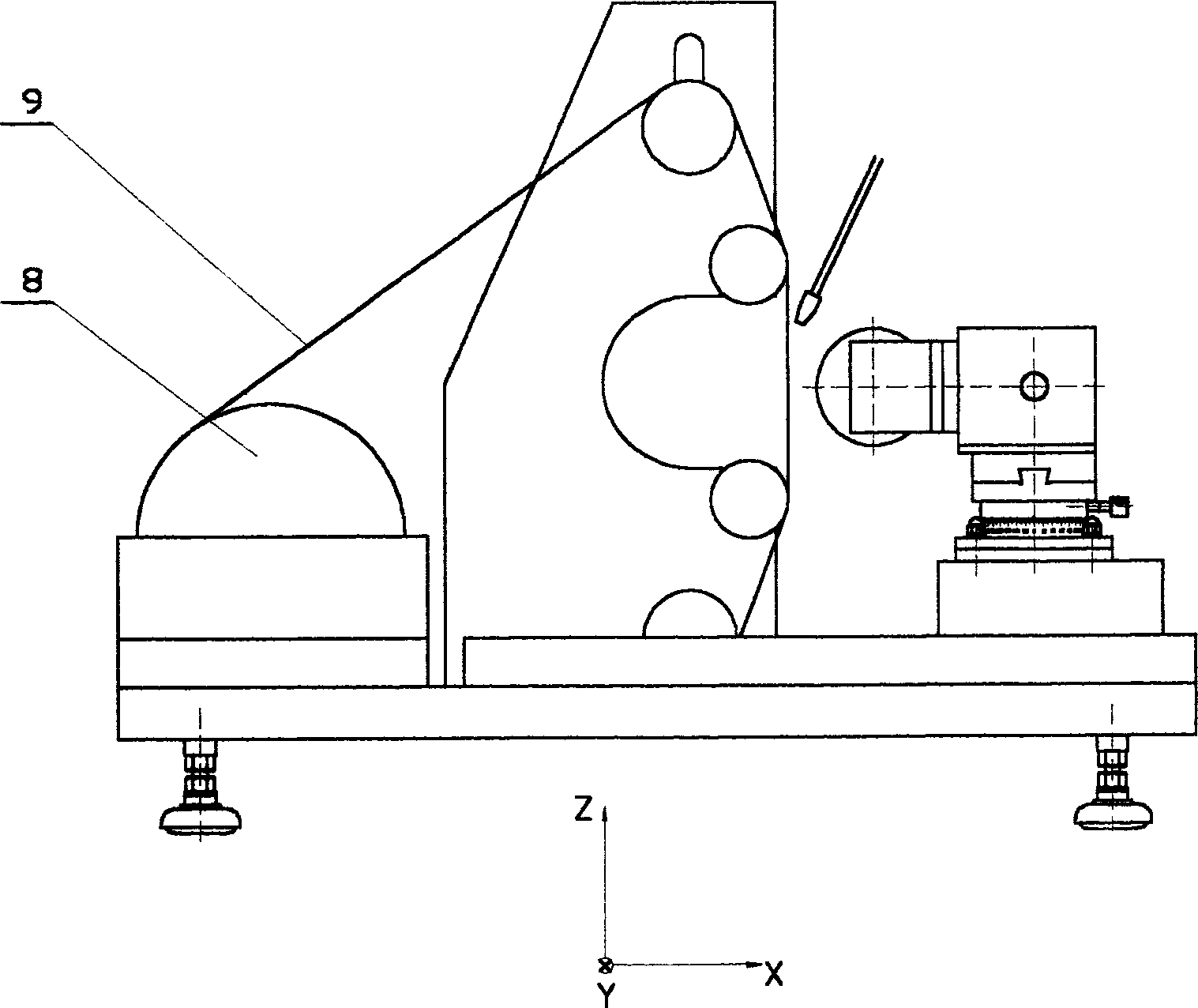

[0020] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in further detail:

[0021] A composite workbench (2) capable of precise linear motion is installed on the machine base (1), and an adjustable work roll and a vertical plate (7) of a tensioner are housed. The compound workbench is composed of the main workbench which can be finely adjusted in the Y-axis direction at the lower part and the work slide table installed on it. The work slide table can stand on the main workbench along the X-axis direction and perform precise linear feed under the main force drive. sports. The working slide table is equipped with a 2-dimensional fixture, a differential scale mechanism or a special cross fixture, and the universal fixture (3) composed of the sample to be cut can be clamped on it, and can be precisely adjusted and clamped on the XOY plane YOZ plane , the slide plate holding the sample can be accurately and quantitati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com