Correcting method for solar water heater capacitance water level sensor measuring value

A solar water heater and water level sensor technology, which is applied to solar thermal power generation, solar thermal devices, liquid level indicators for physical variable measurement, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

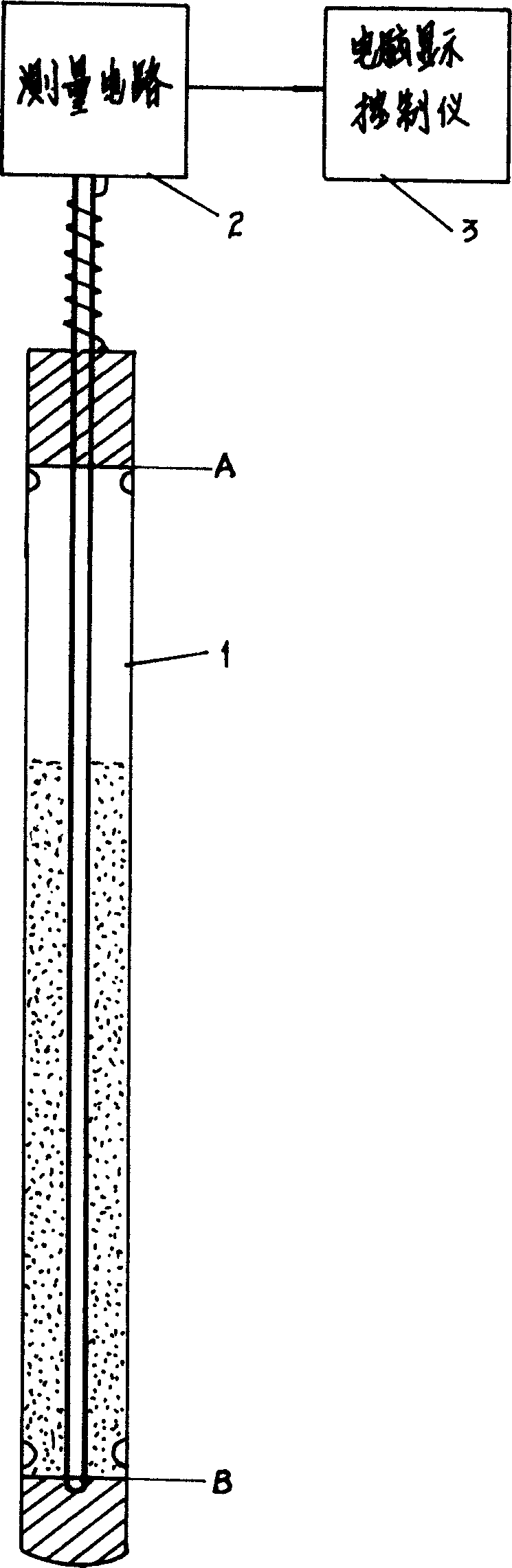

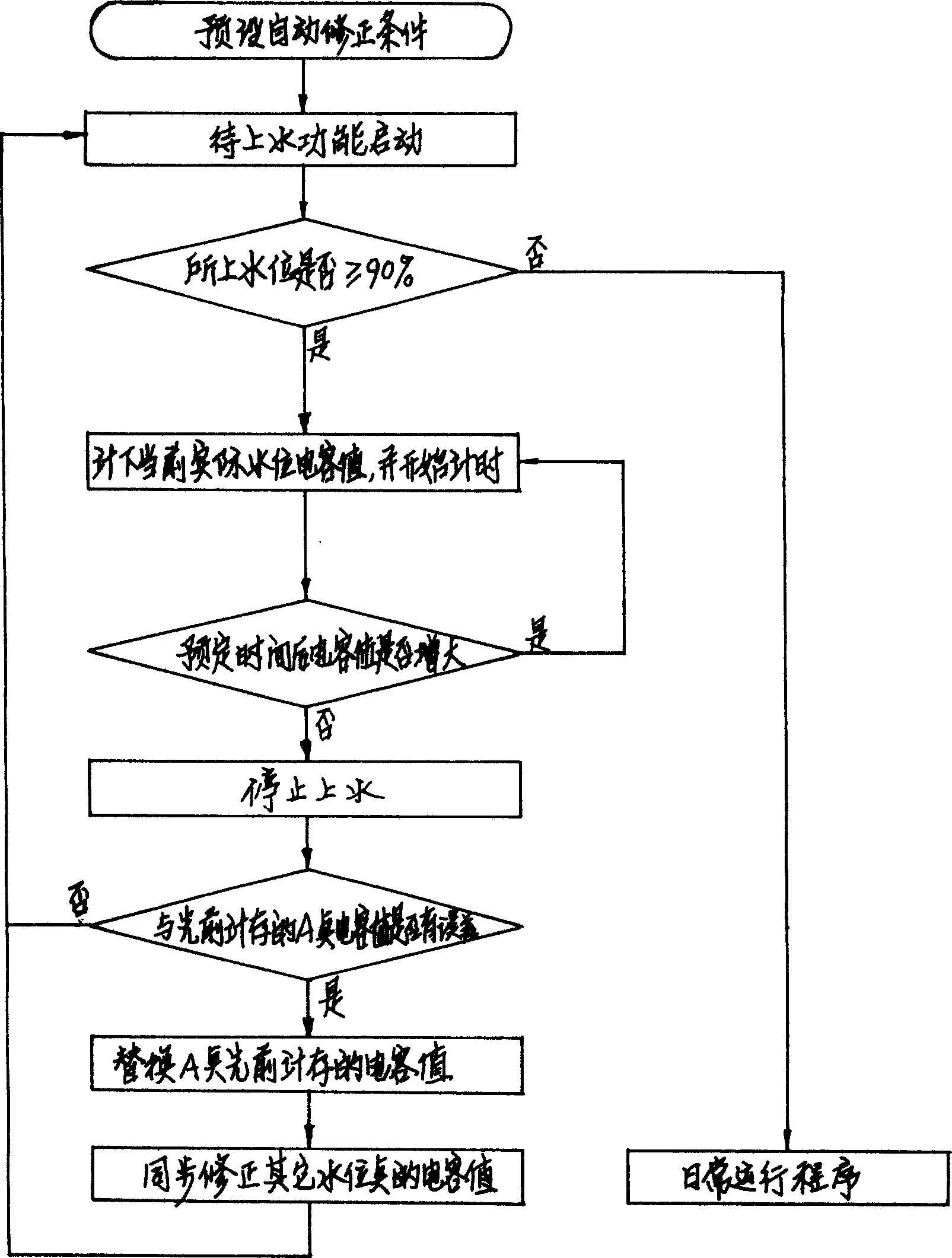

[0017] Figure 1 to Figure 2 As shown, it is a specific embodiment of the method for correcting the measured value of a solar water heater capacitive water level sensor according to the present invention. The capacitive water level sensor includes a capacitive probe 1 and a measuring circuit 2, and is installed on the water storage tank of the solar water heater. The measuring circuit The output end of 2 is connected with computer display controller 3, and described computer display controller 3 carries out real-time monitoring and automatic correction to the measured water storage tank water level by capacitive water level sensor, and its control flow is carried out as follows:

[0018] A. Preset correction conditions;

[0019] The first step is to set the water level detection point and the corresponding capacitance value. Point B is the zero water level point, and point A is the full water level point. The water level detection point set according to the detection accuracy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com