Breakdown test method for medium relative to time in high temperature constant electric field

A dielectric breakdown and testing method technology, applied in the direction of electronic circuit testing, testing dielectric strength, etc., can solve the problems of high cost, short required time, poor error control, etc., and achieve low consumption cost, high testing accuracy, The effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

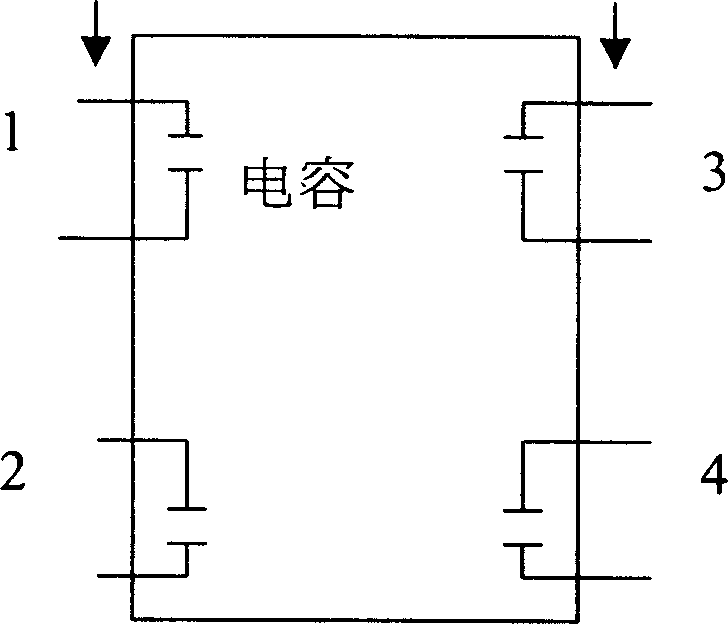

[0017] The time-related dielectric breakdown reliability test method of the present invention also belongs to the package-level test method, and adopts high-temperature constant voltage stress to perform TDDB reliability test on integrated circuit gate oxide layer and dielectric layer test structure. In this embodiment, the test structure uses a thin gate oxide MOS capacitor as the test sample. For the package diagram of the test structure, please refer to figure 1 shown. The test method is carried out as follows:

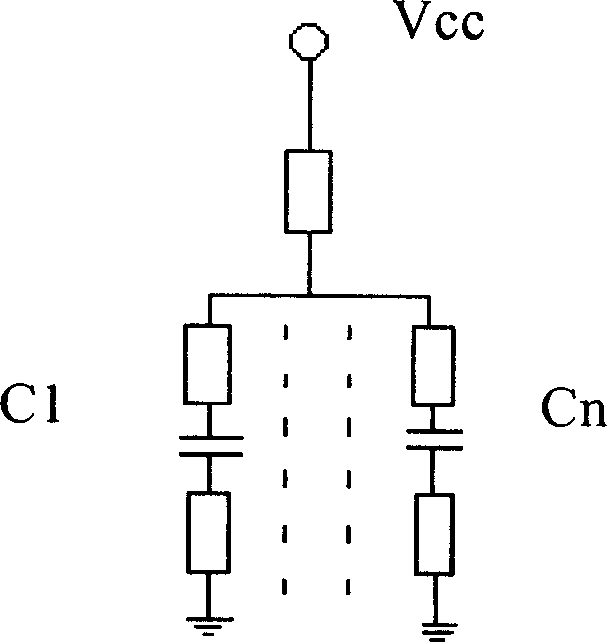

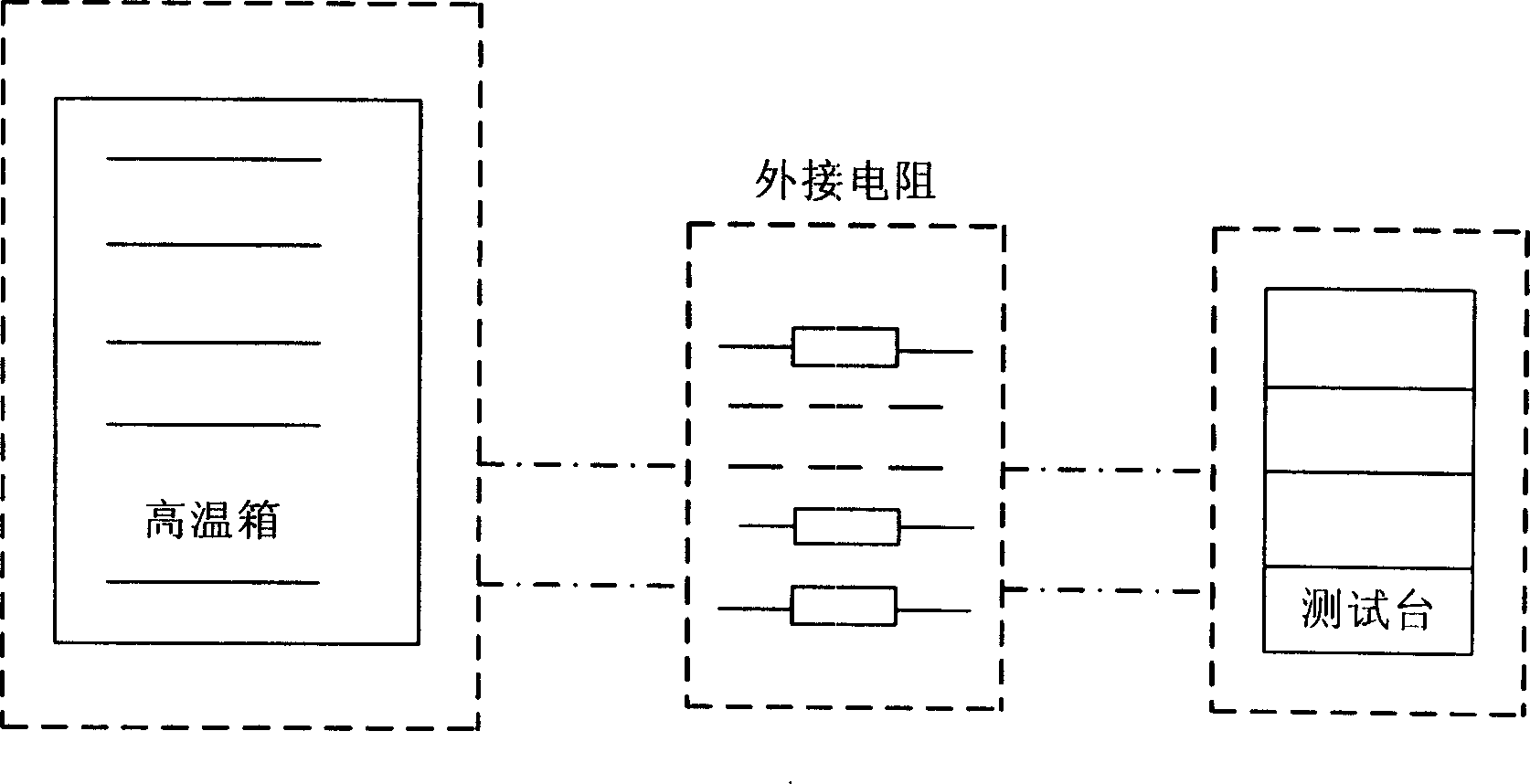

[0018] Step A: To build a test system, first connect the test structure in parallel, then place the test sample in a high-temperature box, then connect the external resistor in series, and finally connect the external resistor to the test bench, see Figure 2 to Figure 3 As shown, first connect the capacitors in parallel, and resistors are connected in series on both sides of the capacitors in the parallel circuit to limit the current, then put the test sample in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com