Chemical fiber printing alkali reducing quantity waste water resources pretreatment method

A technology of alkali reduction wastewater and resource utilization, which is applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the difficulty of chemical fiber printing and dyeing alkali reduction wastewater treatment, and the investment and cost Deal with problems such as high cost and inability to meet the discharge standards stably, and achieve the effects of small footprint, reduced treatment costs, and low waste water treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

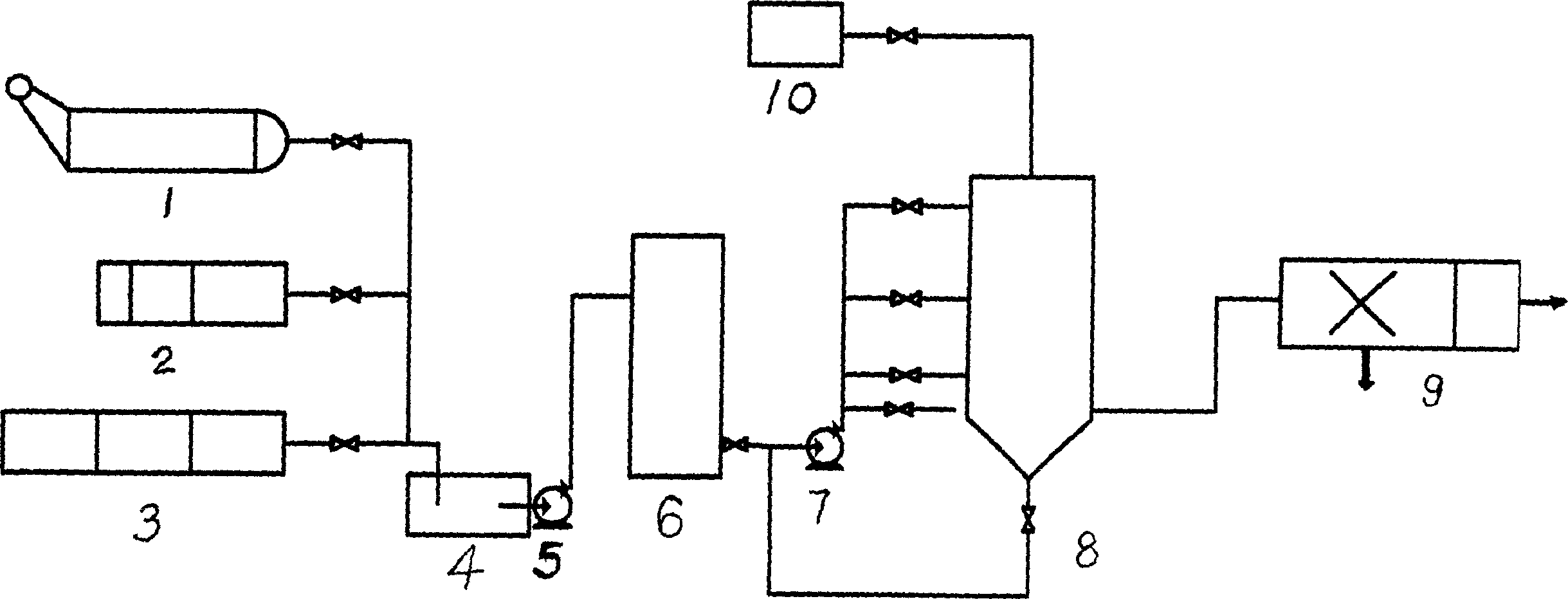

[0017] Example 1: Alkali reduction wastewater treatment of a chemical fiber printing and dyeing enterprise, the wastewater treatment scale is 1500t / d, and the process flow is as follows figure 2 As shown, the alkali reduction wastewater produced by the dyeing vat 1, the intermittent alkali weight reduction machine 2, and the continuous alkali weight reduction machine 3 are firstly collected into the middle tank 4, and the volume of the middle tank 4 is 2 to 20m 3 , the number can be set multiple according to the size of the enterprise and the convenience of fragmented collection. This embodiment has not been connected to the alkali reduction waste water in the dyeing vat. The waste water is transported to the pretreatment storage tank 6 through the pump 5. The CODcr concentration in the waste water is 23660mg / l, and the pH value is 12.5. Because this part of the waste water is alkaline, an alkali-resistant pump and pipeline must be selected. A tee is established between the ...

Embodiment 2

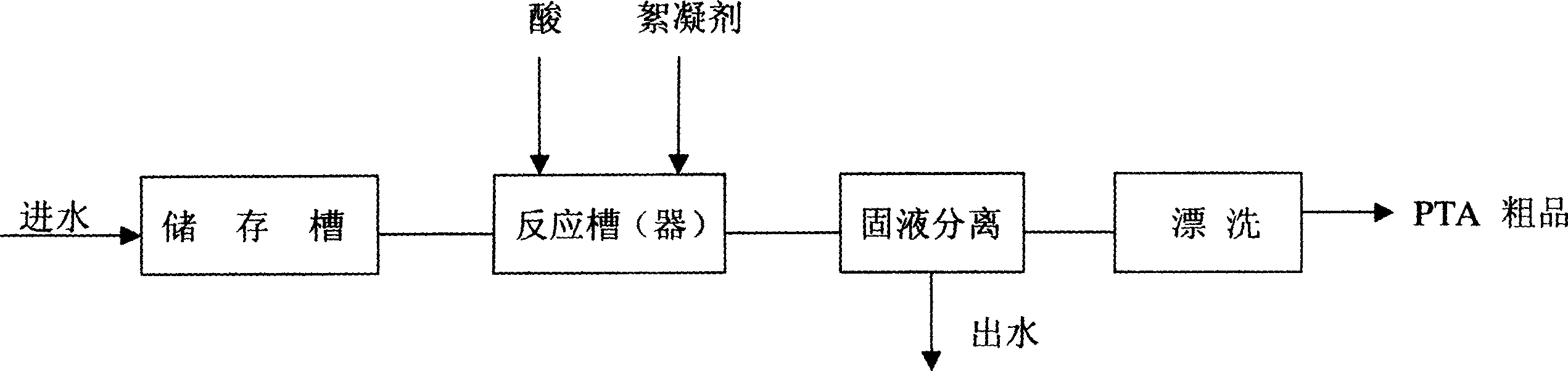

[0019] Example 2: A chemical fiber fabric printing and dyeing company is mainly engaged in the printing and dyeing of chemical fiber fabrics, with an annual processing capacity of 120 million meters. There are 12 intermittent alkali weight reduction machines and 1 continuous alkali weight reduction machine. The daily discharge of high-concentration alkali weight reduction Wastewater about 1000m 3 . Reaction tank volume 25m 3 ×4 units, equipped with 60m 2 2 sets of polypropylene plate and frame filter presses, the storage tank is a concrete high level pool of 400m 3 (Using the original wastewater pool), the daily processing capacity of alkali reduction wastewater is 1000m 3 . Using the chemical fiber printing and dyeing alkali weight reduction wastewater resource pretreatment process flow of the present invention (such as figure 1 shown), use 30% sulfuric acid to adjust the pH value of the wastewater to 2.5-5.0, (if the pH value> 5.0, the precipitation is not complete), th...

Embodiment 3

[0022] Example 3: A group company engaged in printing and dyeing of chemical fiber and cotton cloth has 40 intermittent alkali weight reduction machines and one continuous alkali weight reduction machine, and discharges 1,500-2,000 tons of alkali weight reduction waste water per day. Processing device is located 500m 3 One storage tank, 25m 3 There are 6 reaction tanks and 2 plate and frame filter presses, with a daily processing capacity of 1500t / d. Adopt technological process described in the present invention (as figure 1 shown). Use 25% sulfuric acid to adjust the pH value of the wastewater to 2.5-5, add the flocculant to 3-50ppm, and keep stirring for 15-45min. The comparison of water quality analysis results before and after pretreatment of alkali reduction wastewater is shown in Table 3.

[0023] indicators

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com