Structure ordered product, method of producing the same and applications of the same

An orderly and structured technology, applied in chemical instruments and methods, layered products, nanotechnology for materials and surface science, etc., can solve problems such as expensive temperature, sensitivity, and changing component properties of liquid crystal materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

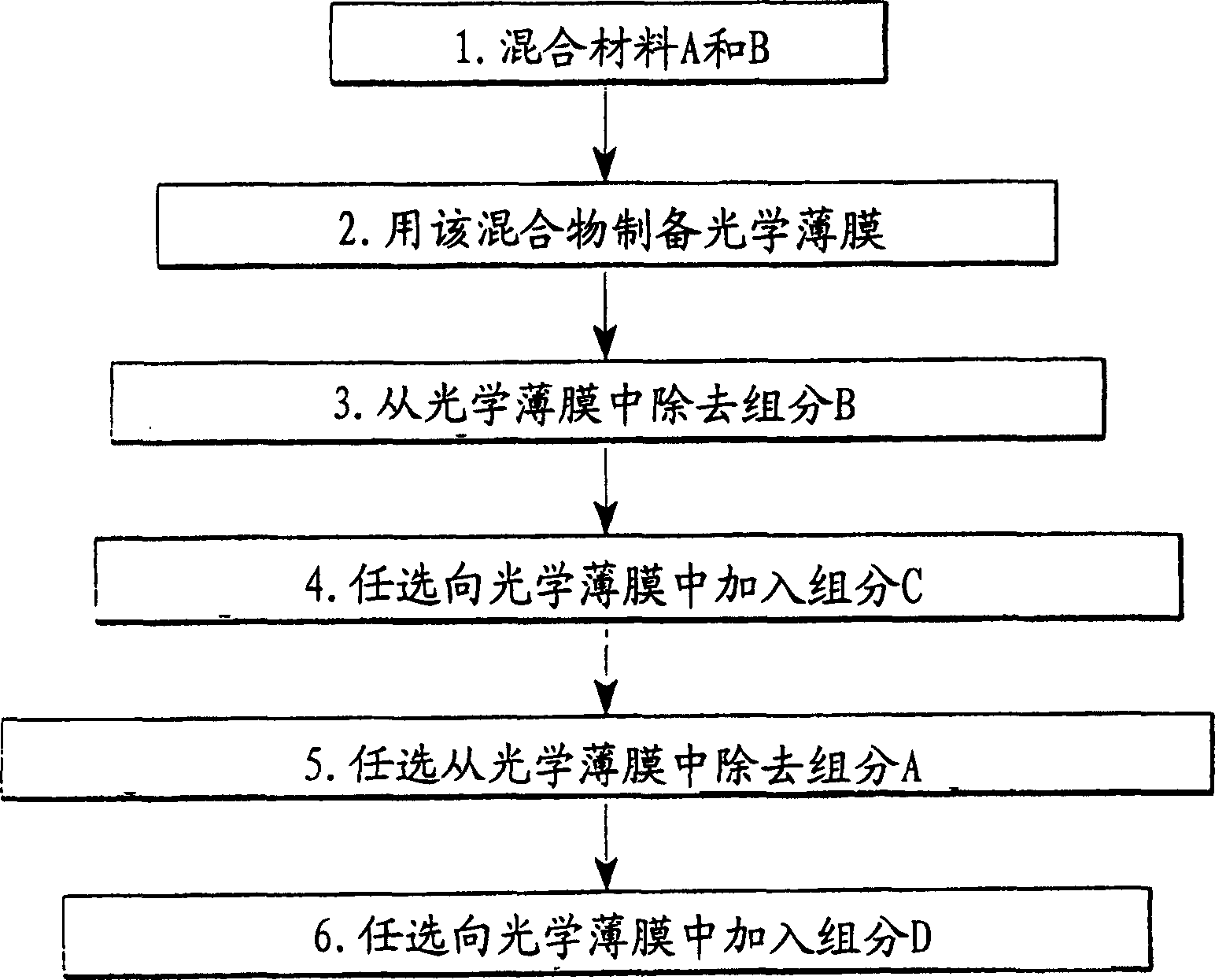

Method used

Image

Examples

Embodiment 1

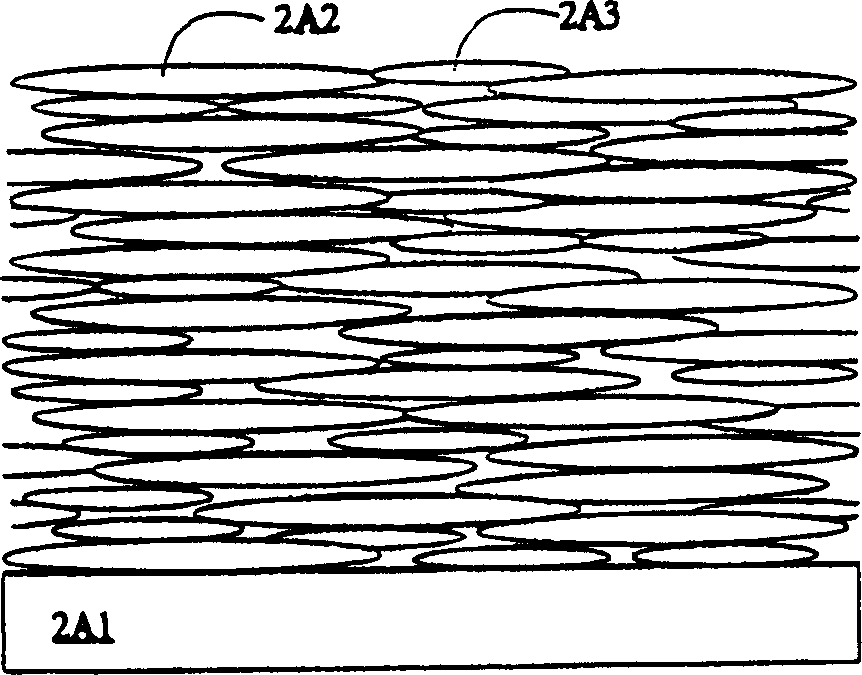

[0062] Figure 4A Experimental reflectance spectra of film samples prepared according to the method of the present invention are shown. Curve 4A1 is the reflection of a planar CLC film of a blend of BASF Acrylate CLC Polymer #181 (45 wt%), chiral nematic (53 wt%), and a small amount of Ciba-Geigy photoinitiator Irgacure 184 (2 wt%) spectrum. The chiral nematic itself consists of Merck low molecular weight nematic liquid crystal E44 and a chiral dopant R1011 (0.7 wt% based on chiral nematic). The films were 20 μm thick and were produced in the conventional manner, ie first spin-coating a mechanically rubbed positioning layer of polyimide on two glass substrates. Glass beads having a diameter of 20 μm were then dispersed between the two glass substrates so that the coated sides faced each other. The CLC blend is then introduced between the substrates by capillary action. After mechanical shearing (small lateral movement of the substrate forces the LC molecules to align), the...

Embodiment II

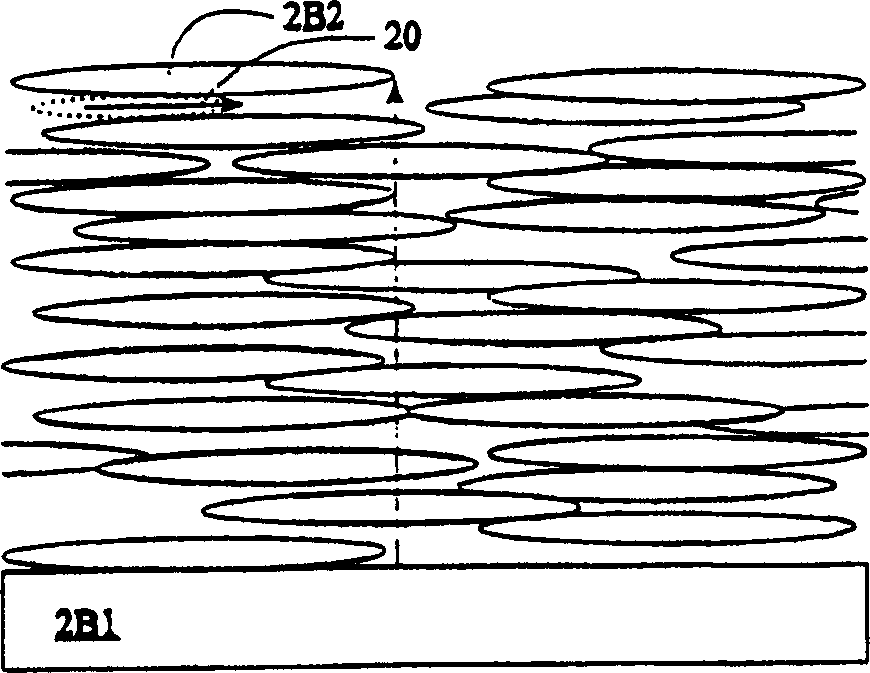

[0064] Figure 4BExperimental reflectance spectra of film samples prepared according to the method of the present invention are shown. Curve 4B1 is the spectrum of a planar CLC film of a blend of BASF acrylate CLC polymer #181 (26 wt%), chiral nematic (69 wt%) and a small amount of Ciba-Geigy photoinitiator Irgacure 184 (5 wt%) . The chiral nematic itself consists of Merck low molecular weight nematic liquid crystal E44 and chiral dopant CB15 (24.4% by weight based on chiral nematic). The film was 20 μm thick and was prepared in a similar manner to Example 1 above. After photopolymerizing the film samples with a UV lamp and removing one of the substrates, the reflective layer 4A1 was removed from the "bare" film side. In the context of the above discussion, A is BASF 181 polymer and B is a low molecular weight chiral nematic. Films containing the blend (A+B) were prepared. Subsequent removal of component B (low molecular weight chiral nematic) by dissolution with acetone ...

Embodiment III

[0066] Figure 4C Experimental reflectance spectra of film samples prepared according to the method of the present invention are shown. Curve 4C1 is the reflection of a planar CLC film of a blend of BASF acrylate CLC polymer #181 (45 wt%), chiral nematic (53 wt%), and a small amount of Ciba-Geigy photoinitiator Irgacure 184 (2 wt%) spectrum. The chiral nematic itself consists of Merck low molecular weight nematic liquid crystal E44 and a chiral dopant R1011 (0.7 wt% based on chiral nematic). The film was 20 μm thick and was prepared in a similar manner to that described above. After photopolymerizing the film samples with a UV lamp and removing one of the substrates, the reflective layer 4A1 was removed from the "bare" film side. In the context of the above discussion, A is BASF 181 polymer and B is a low molecular weight chiral nematic. Films containing the blend (A+B) were prepared. Subsequently, component B (low molecular weight chiral nematic) was removed by dissolvin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com