Array method for drill spindles of printed circuit board drilling machine or forming machine

A printed circuit board, drilling machine technology, applied in the direction of printed circuit, printed circuit manufacturing, drilling/drilling equipment, etc., can solve the problems of increased investment cost, long, sometimes more than 12 hours, low efficiency, etc. To achieve the effect of reducing cost and time and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

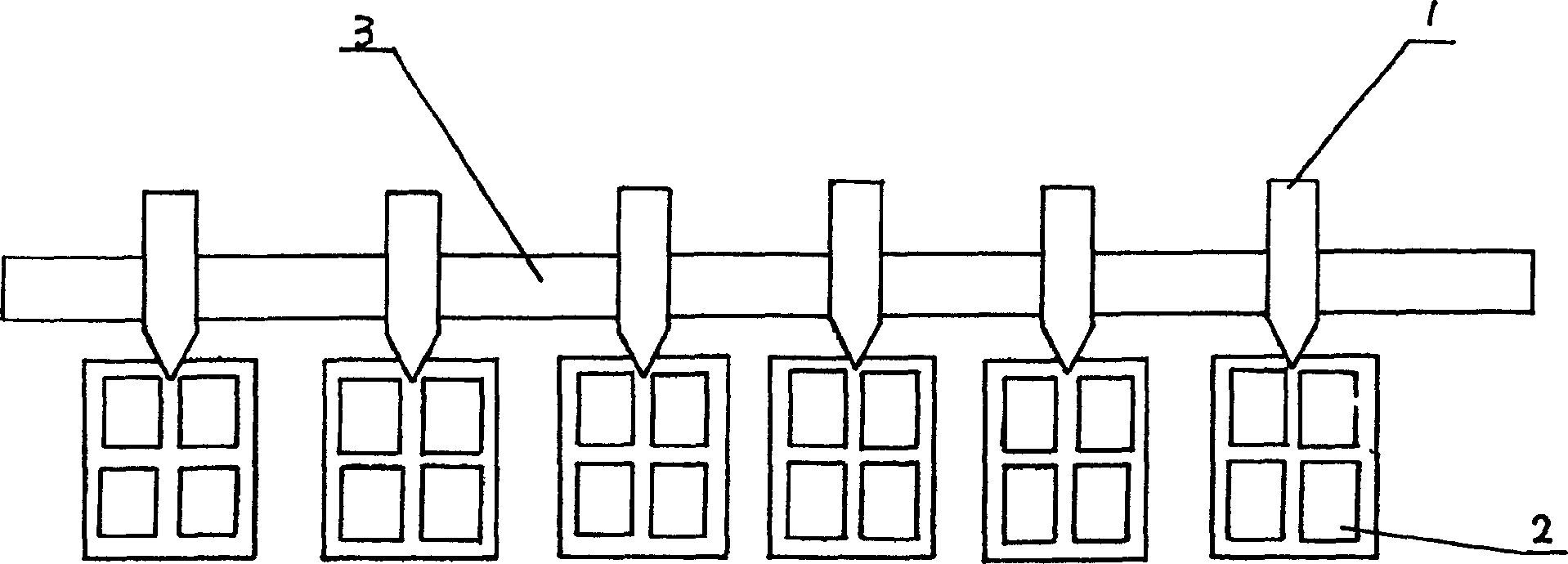

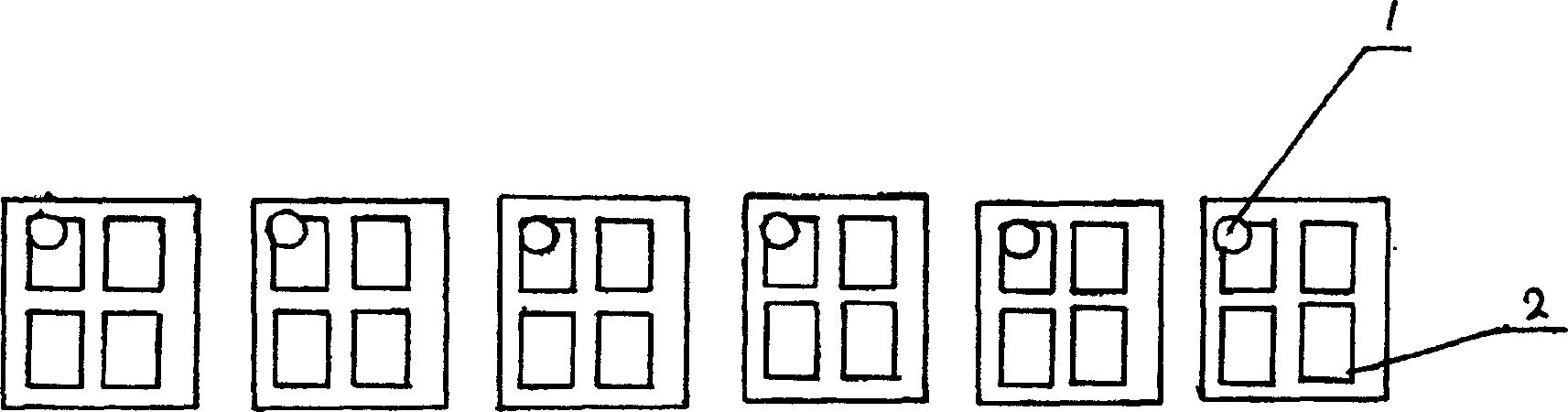

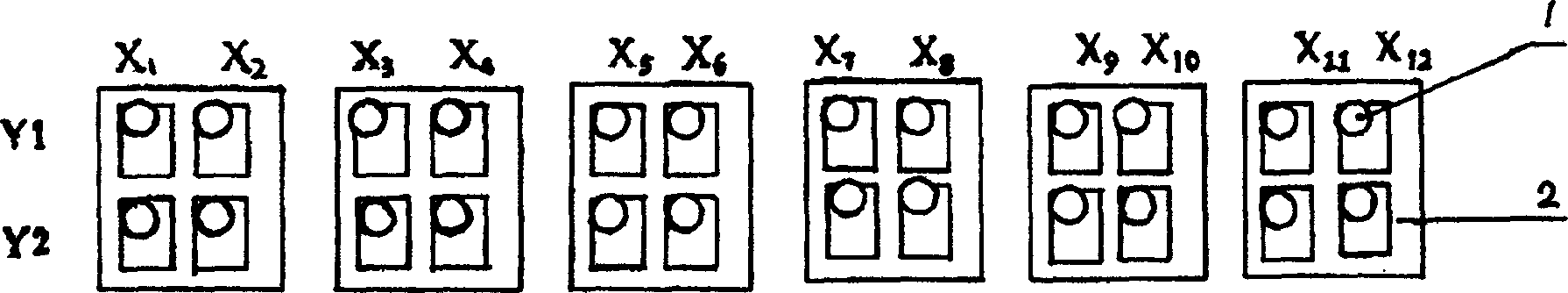

[0014] Such as image 3 , On the drilling machine or molding machine above the printed circuit board 2, the present invention arranges the drilling shafts 1 in a matrix, such as two rows Y1, Y2, and twelve columns X1, X2, -X12. Before drilling, move and adjust the drilling axis according to the layout spacing (drilling spacing). For example, the Y1 row is fixed, and the Y2 row moves as a whole column according to the layout spacing. Columns X4, X6, X8, X10, and X12 are moved as a whole according to the typesetting spacing; of course, all of them can be adjusted. After each axis is set, the drilling operation can be started. In this way, the same drilling machine or molding machine only needs to increase the number of drilling shafts, and the drilling time can be shortened by matrix arrangement. The time spent in this embodiment is 1 / 4 of the original, that is, the efficiency is 4 times of the original. In the future, with the increase of the number of layouts in the board a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com