Method for producing L-ornithine hydrochloride

A technology of ornithine hydrochloride and arginine hydrochloride, which is applied in the field of preparation of L-ornithine hydrochloride, can solve the problems of unseen production patents and related reports, amino acid racemization, etc., and achieve The effect of shortening the production cycle, reducing the amount of resin, and improving the yield of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

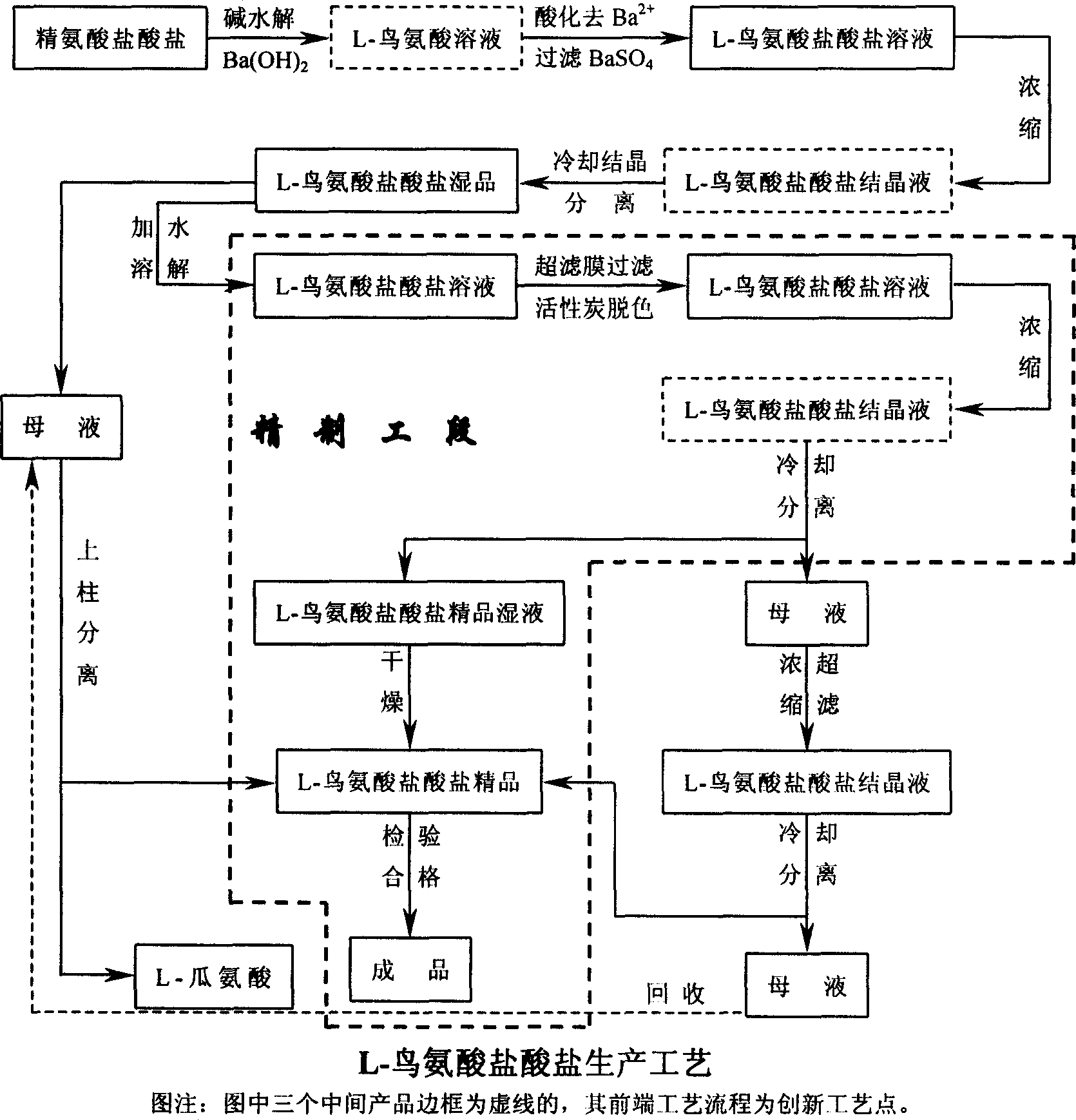

Image

Examples

Embodiment Construction

[0010] Because amino acids are more likely to undergo racemization reactions in alkaline media, we control the reaction conditions so that the resulting products do not undergo racemization; the properties of amino acids are very close, and it is difficult to separate and purify by general methods. We use ion exchange resins Chromatography solves the recovery and purification of L-ornithine hydrochloride in the mother liquor. For this reason, we screen the optimum temperature, the most appropriate weak base substance and arginine hydrochloride and OH - Concentration, including appropriate hydrolysis reaction time, so that racemization does not occur:

[0011] At 100~110℃, 0.4~0.5M weak lye Ba(OH) 2 Hydrolyze L-arginine hydrochloride in medium for 2-3 hours, neutralize with dilute sulfuric acid to remove Ba 2+ , Concentrated and crystallized to obtain L-ornithine hydrochloride crystal crude product, the crude product was recrystallized in pure water to obtain pure product, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com