Optical calibrating apparatus and method of laser ranging system

A laser ranging and calibration device technology, which is applied in the direction of measuring devices, radio wave measuring systems, electromagnetic wave re-radiation, etc., can solve the problem of not being able to quantitatively give the coincidence degree of the transmitting and receiving fields of view, and the accuracy of optical calibration is limited, etc. problem, to achieve the effect of protection safety, high work efficiency and high calibration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

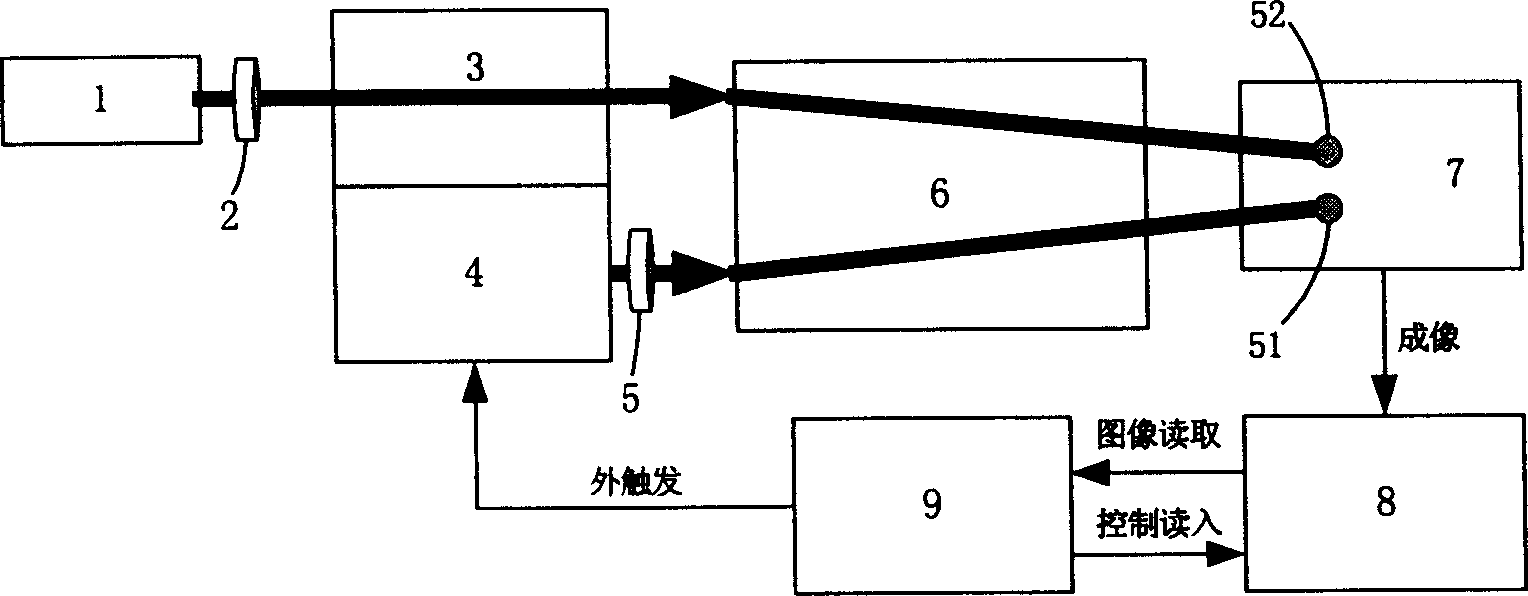

[0030] see first figure 1 , figure 1 It is a structural schematic diagram of the optical calibration device of the laser ranging system of the present invention. It can be seen that the optical calibration device of the laser ranging system of the present invention

[0031] An optical calibration device for a laser ranging system, comprising a receiving optical system 3 and a laser 4, characterized in that the receiving optical system 3 is preceded by a receiving field of view simulation laser 1, and after the receiving optical system 3 and the laser 4 is a collimator 6 After the collimator 6, an image screen 7 is set perpendicular to its main axis, behind the image screen 7 is an area array CCD8, and the area array CCD8 is connected with a computer 9, and the RS322 serial port of the output port of the computer 9 is connected with the laser 4 and the receiving field of view The external trigger source of analog laser 1 is connected. The working process of the device of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com