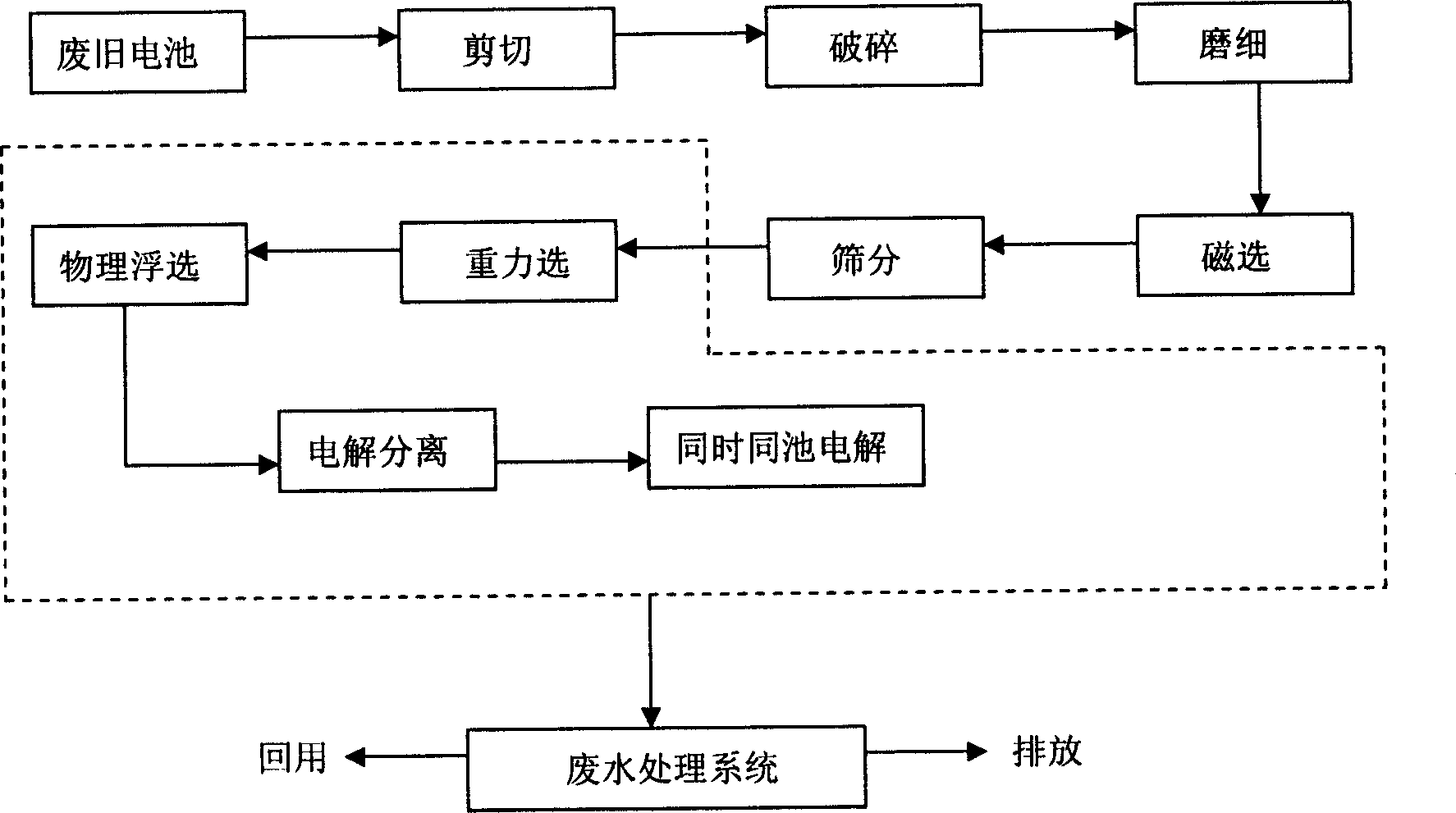

Process for separating and purifying ziuc and manganese dioxide in comprehensiv treating waste battery

A manganese dioxide, waste battery technology, applied in the direction of electrolysis process, electrolysis components, improvement of process efficiency, etc., can solve the problems of intensified harmful effects of impurities, difficulty in meeting technical requirements, product quality of zinc sintered plates, etc., and improve working conditions. and working environment, high purity, rich raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0047] Using 50kg of waste batteries, after the crushing process, 7.1kg of zinc skin was obtained; 6.5kg of mixed materials such as plastics, copper caps, and iron sheets, and a total of 30kg of mixed materials containing zinc powder and manganese dioxide powder were obtained by direct electrolytic separation. 1.2 kilograms of manganese were electrolyzed in the same cell at the same time to obtain 3.3 kilograms of electrolytic zinc and 8.1 kilograms of manganese dioxide.

[0048] Chemical composition analysis during separation and purification process:

[0049] Zn

[0050] Zn

[0051] The above mixture is electrolytically separated in sulfuric acid medium, the current density is: 120A / cm 2 , the cell voltage was 3.0V, and 5kg of manganese dioxide powder was obtained.

[0052] MnO 2

[0053] Electrolyze the remaining solution that has been preliminarily separated in the same cell at the same time, and the current density is: 10A / cm 2 , the effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com