Soft investigating method for overflow grain index of ore grinding system based on case inference

A soft measurement, case-based technology, applied in measurement devices, particle size analysis, particle and sedimentation analysis, etc., can solve problems such as lack of guidance, large human factors, and long measurement time intervals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

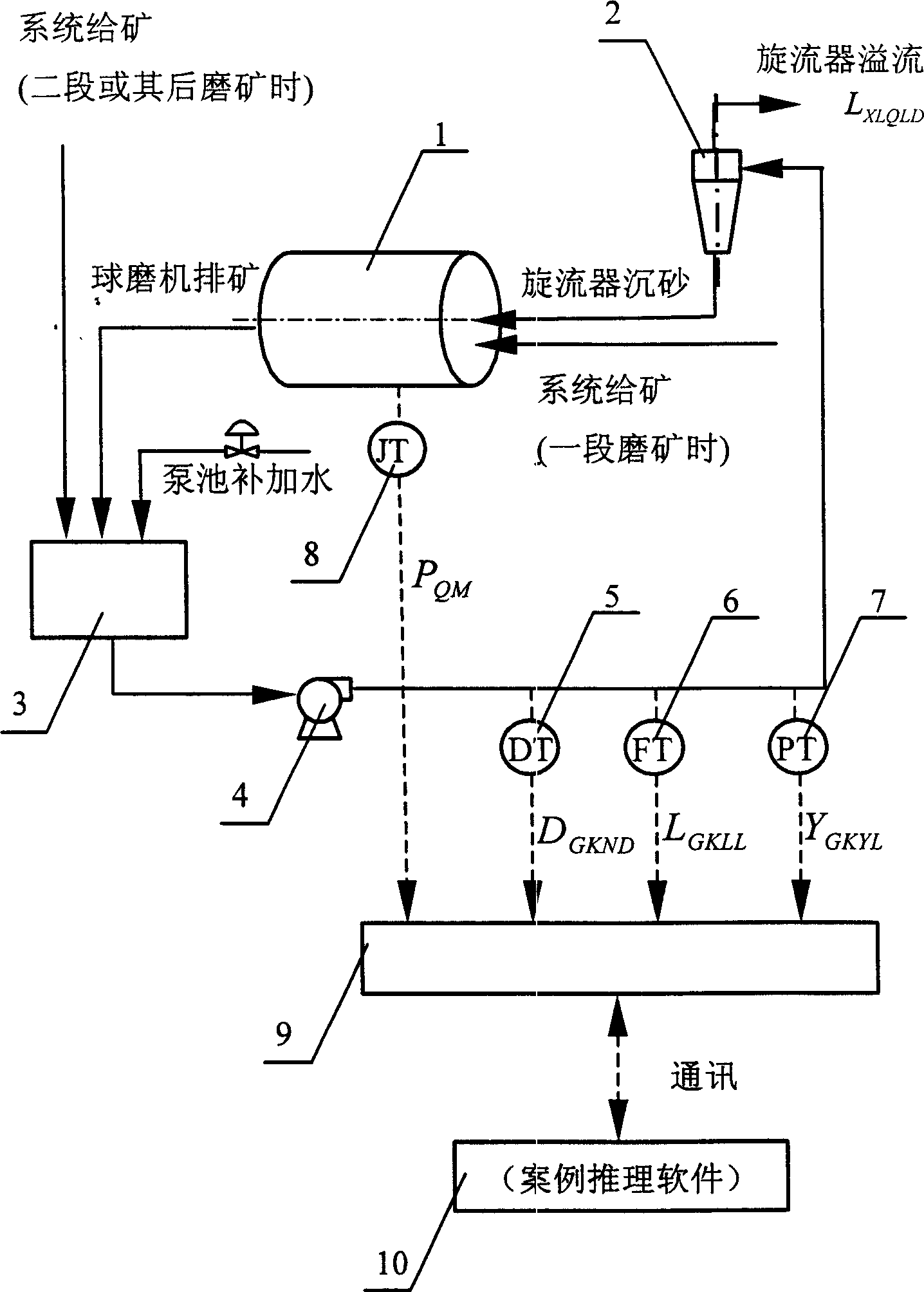

[0109] Taking the strong magnetic grinding and grading section of a large iron ore dressing plant as an example, the main iron ore of the dressing plant is pyrite and limonite, and the gangue is mainly barite, quartz, jasper and iron dolomite , the actual iron content of the ore is 33%. The strong magnetic separation system separates powder ore below 0-15mm, and adopts two stages of continuous grinding process. The lattice type ball mill forms a closed circuit with the hydrocyclone.

[0110] The schematic diagram of the two-stage grinding system is as follows: figure 1 As shown: the first-stage grinding product overflows from the classifier into the pump pool, and then is pumped into the cyclone by the rubber pump, and the grit part of the cyclone enters the second-stage ball mill for regrinding. Adding water flows into the pump pool by itself, forming a closed circuit. The cyclone overflow enters the subsequent sorting process.

[0111] The model of the ball mill is φ3200×...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com