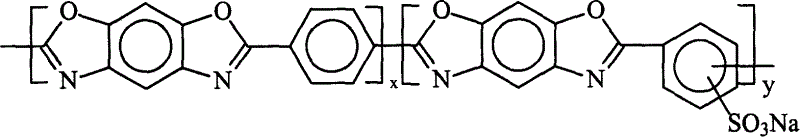

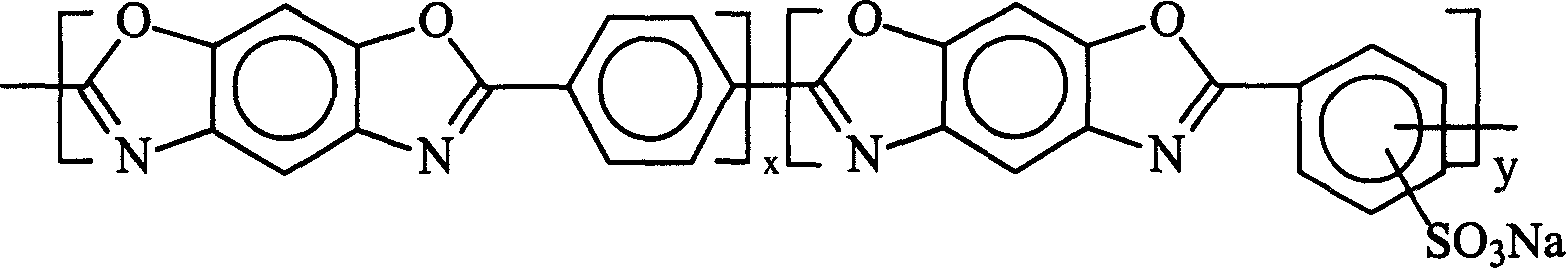

Poly-benzobisoxazole polymer containing ion group and process for preparing same

A technology of polybenzobisoxazole and ionic group, applied in the field of polybenzobisoxazole polymer and its preparation, can solve the problem of insufficient compressive strength, torsional modulus, poor adhesion between fiber and matrix, and low tensile strength. Tensile strength and other issues, to achieve the effect of improving mechanical properties, improving interface properties, and improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

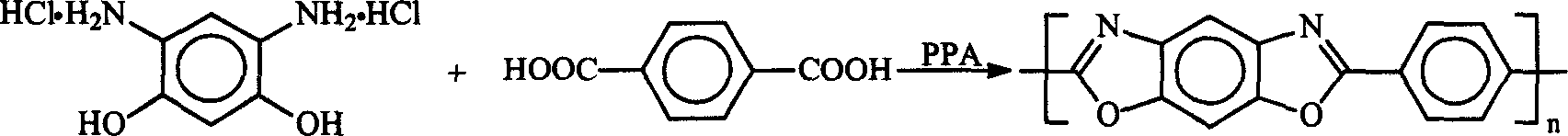

Method used

Image

Examples

Embodiment 1

[0028] When equipped with a strong stirring device, N 2 Import and export, into the 0.5L reactor at the feeding port, first pass high-purity N 2 Displacing the air, at N 2 Under protection, add 13.3675g 4,6-diaminoresorcinol hydrochloride (DAR), 10.2095g terephthalic acid (TPA), 0.3364g 5-sodium sulfonate-1,3-isophthalic acid (SIPA) ), 53.54g polyphosphoric acid (PPA) (P 2 o 5 Concentration is 80wt%) and 26.89g P 2 o 5 , Seal the reactor.

[0029] Raise the temperature of the reaction materials in the reactor to 50°C and keep for 1 hour to make the materials mix initially, then slowly raise the temperature to 65°C and keep for 2 hours to further dissolve the materials. Raise the temperature of the reaction kettle to 100°C and react for 24 hours until the neutral color is detected at the gas escape port with pH test paper, which means that the system has completely removed HCl. Raise the temperature to 130°C for 3 hours, 150°C for 5 hours, then raise the temperature to 1...

Embodiment 2

[0032] When equipped with a strong stirring device, N 2 Import and export, into the 0.5L reactor at the feeding port, first pass high-purity N 2 Displacing the air, at N 2 Under protection, add 15.4219g 4,6-diaminoresorcinol hydrochloride (DAR), 9.6152g terephthalic acid (TPA), 3.8808g 5-sodium sulfonate-1,3-isophthalic acid (SIPA) ), 56.72g polyphosphoric acid (PPA) (P 2 o 5 Concentration is 80wt%) and 29.36g P 2 o 5 , Seal the reactor.

[0033] Raise the temperature of the reaction materials in the reactor to 50°C and keep for 1 hour to make the materials mix initially, then slowly raise the temperature to 65°C and keep for 3 hours to further dissolve the materials. Raise the temperature of the reactor to 100°C and react for 30 hours, until the pH test paper is used to detect a neutral color at the gas escape port, which means that the system has completely removed HCl. Raise the temperature to 130°C for 1.5 hours, 150°C for 3 hours, then raise the temperature to 175°...

Embodiment 3

[0036] When equipped with a strong stirring device, N 2 Import and export, into the 0.5L reactor at the feeding port, first pass high-purity N 2 Displacing the air, at N 2 Under protection, 11.3917g 4,6-diaminoresorcinol hydrochloride (DAR), 8.7005g terephthalic acid (TPA), 0.2867g 2-sodium sulfonate-1,4-terephthalic acid (SPPA ), 52.98g polyphosphoric acid (PPA) (P 2 o 5 Concentration is 80wt%) and 26.91g P 2 o 5 , Seal the reactor.

[0037]Raise the temperature of the reaction materials in the reactor to 50°C and keep for 1 hour to make the materials mix initially, then slowly raise the temperature to 65°C and keep for 3 hours to further dissolve the materials. Raise the temperature of the reaction kettle to 100°C and react for 20 hours until the neutral color is detected at the gas escape port with pH test paper, which means that the system has completely removed HCl. Raise the temperature to 130°C for 1 hour, 150°C for 5 hours, then raise the temperature to 175°C fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Compression modulus | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com