Prepn process of nano level tungsten powder and WC powder

A nano-scale, tungsten carbide technology, applied in the direction of tungsten/molybdenum carbides, carbides, etc., can solve the problems of reducing the mechanical properties and physical properties of pure tungsten materials, pressure processing performance, etc., to achieve easy addition, narrow particle size distribution, particle size uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

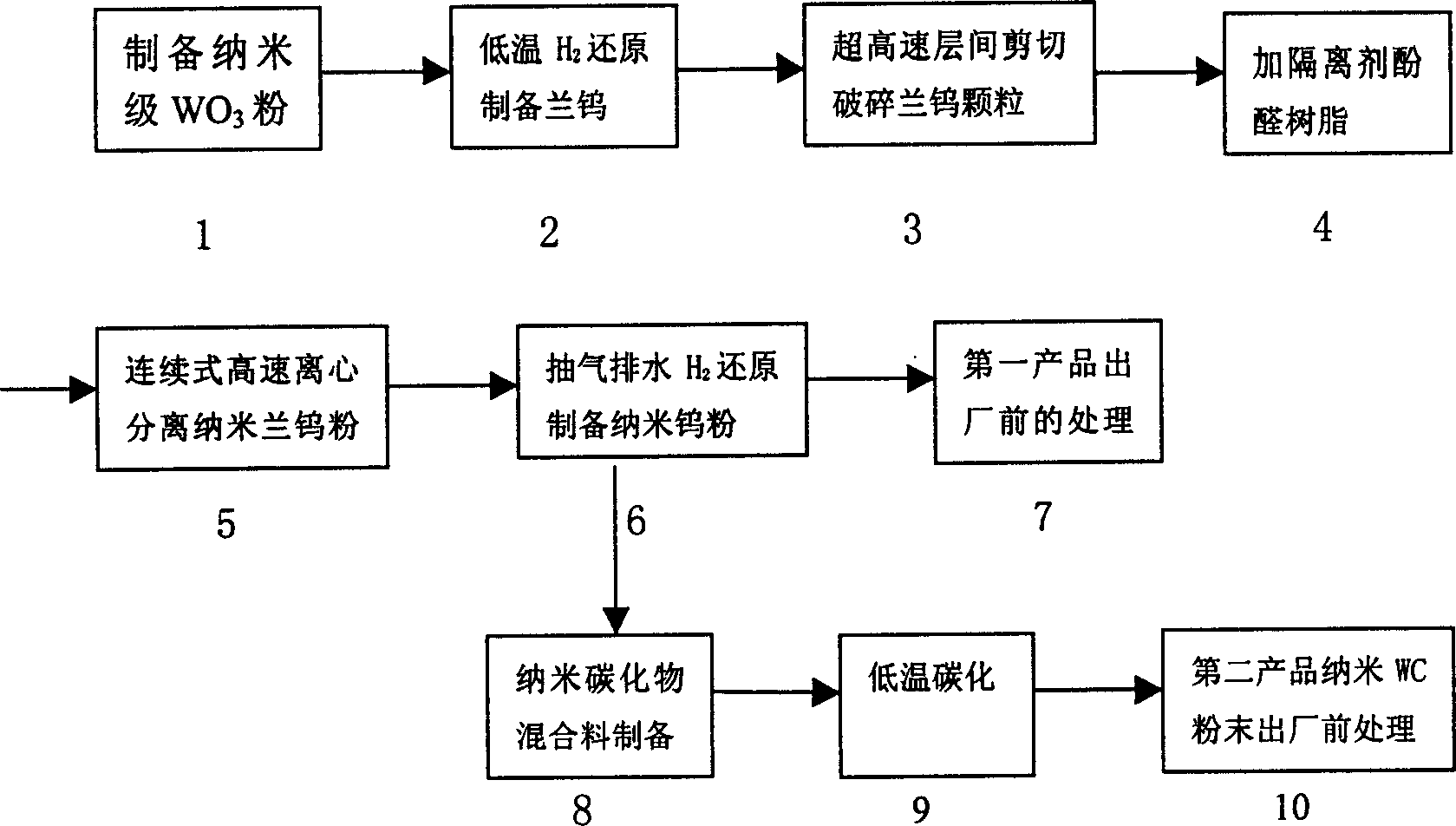

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1, when preparing 10kg nanometer W powder and 10.652kg nanometer WC powder, should complete according to the following steps

[0036] 1. Preparation of nano-WO 3 powder

[0037] Weigh 34.08 liters of high-concentration ammonium tungstate solution, its WO 3 The content is 370g / liter, using the supersonic spray heat transfer method at an air jet pressure of 3.5MPa and a jet speed of 700m s -1 , The spray angle of the nozzle α=45°, the focal length F=13mm, according to 350ml / min, the liquid flow delivery speed is 320ml / min, the hot air temperature is 350°C, and the countercurrent hot air drying is used to make 12.61kg nano-scale WO 3 Powder, average particle size ≤50nm.

[0038] 2. H 2 Preparation of loose and porous blue tungsten powder by reduction

[0039] Use a stainless steel tubular reduction furnace at 500°C for 60 minutes, H 2 Gas section flow rate 20ml / cm 2 . Minutes, reduced to make loose porous blue tungsten powder, the average particle size ≤ ...

Embodiment 2

[0061] Embodiment 2: when preparing 1kg nanometer W powder and 1.0652kg nanometer WC powder, should finish according to the following steps:

[0062] 1. Weigh 3.6 liters of high-concentration ammonium tungstate solution, its WO 3 The content is 350g / liter, the air injection pressure is 2.5MPa, and the injection velocity is 650m·s -1 , Hot air temperature 250 ℃ countercurrent hot air drying, supersonic spray heat transfer method to make nano-scale WO 3 powder. The injection angle α=45 ° of nozzle, focal length F=13mm, by 280ml / min liquid flow conveying speed, make 1.26kg nanoscale WO 3 Powder, average particle size ≤50nm.

[0063] 2. H 2 Preparation of loose and porous blue tungsten powder by reduction

[0064] Stainless steel tubular reduction furnace 420°C, H 2 Gas section flow rate 20ml / cm 2 . Divide, keep warm for 80 minutes, and reduce to make loose and porous blue tungsten powder, with an average particle size of ≤40nm.

[0065] 3, 4, are exactly the same as 3, 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com