Microwave heating regeneration diesel oil engine carbon smoke particulate filter

A particle filter and microwave heating technology, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve problems such as gaps and large expansion coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

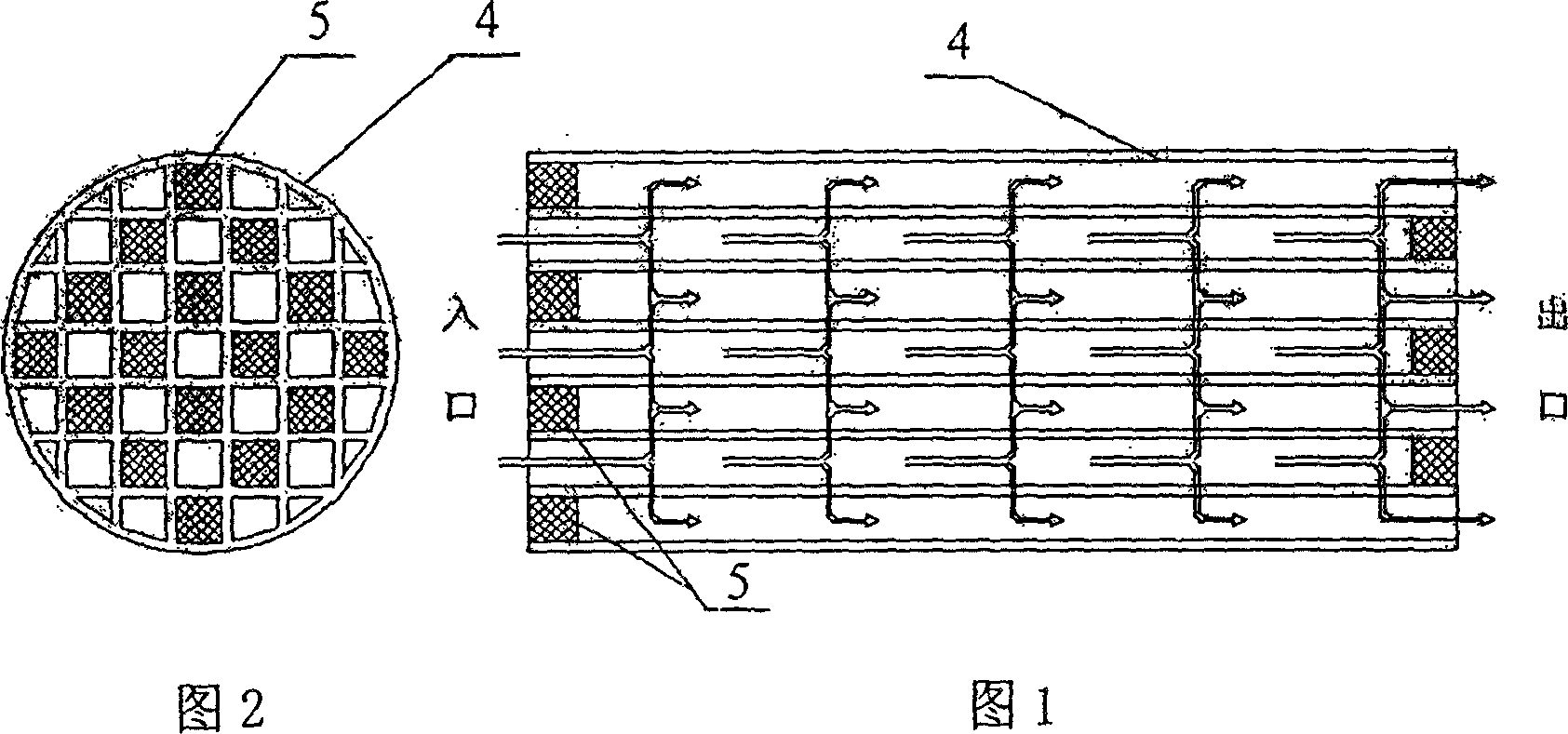

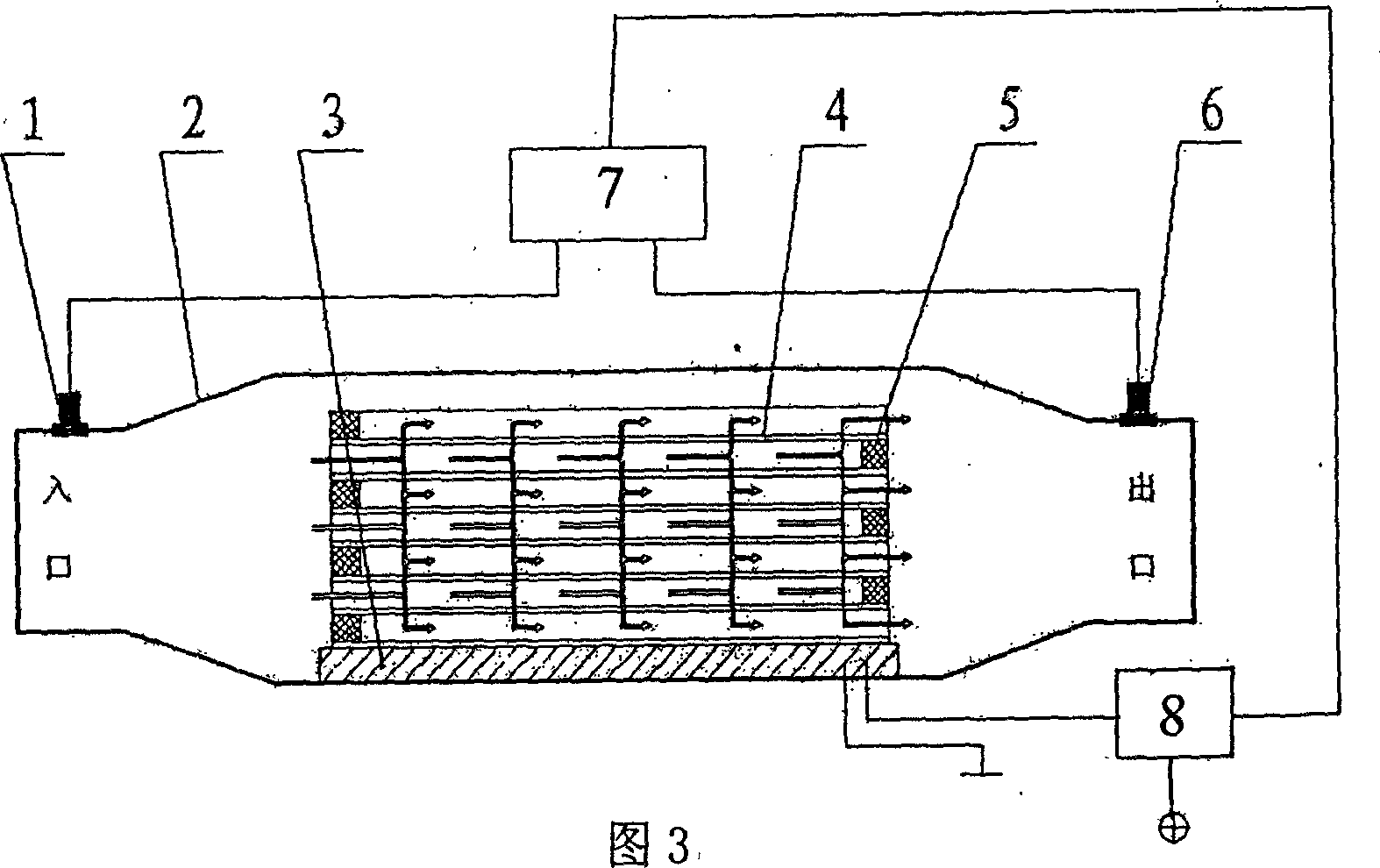

[0018] As shown in Figure 3, the present invention comprises porous ceramic tubes 4 distributed at equal intervals, the nozzles at one end of the porous ceramic tubes 4 are blocked with ceramics 5 at intervals, and the nozzles at the other end of the porous ceramic tubes 4 are opposite to the nozzles at one end. A wall-flow honeycomb ceramic filter with ceramic plugging 5 for intervals, and an electronic control system 7 . A microwave element 3 is installed outside the wall-flow honeycomb ceramic filter, and a microwave heating tube is used in Fig. 3. The wall-flow honeycomb ceramic filter and the microwave element 3 are installed in the metal material shell 2, and the exhaust gas at one end of the metal material shell 2 The inlet end and the exhaust gas outlet end of the other end of the metal material casing 2 are respectively provided with an intake pressure sensor 1 and an exhaust pressure sensor 6, and one end of the microwave element 3 is connected to the positive pole of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com