Occluded foreign substance in metal materials particle-size in-situ statistical distribution analysis method

A statistical distribution and analysis method technology, applied in the field of analysis materials, can solve the problems of not being suitable for fast analysis, cumbersome analysis process, slow analysis speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

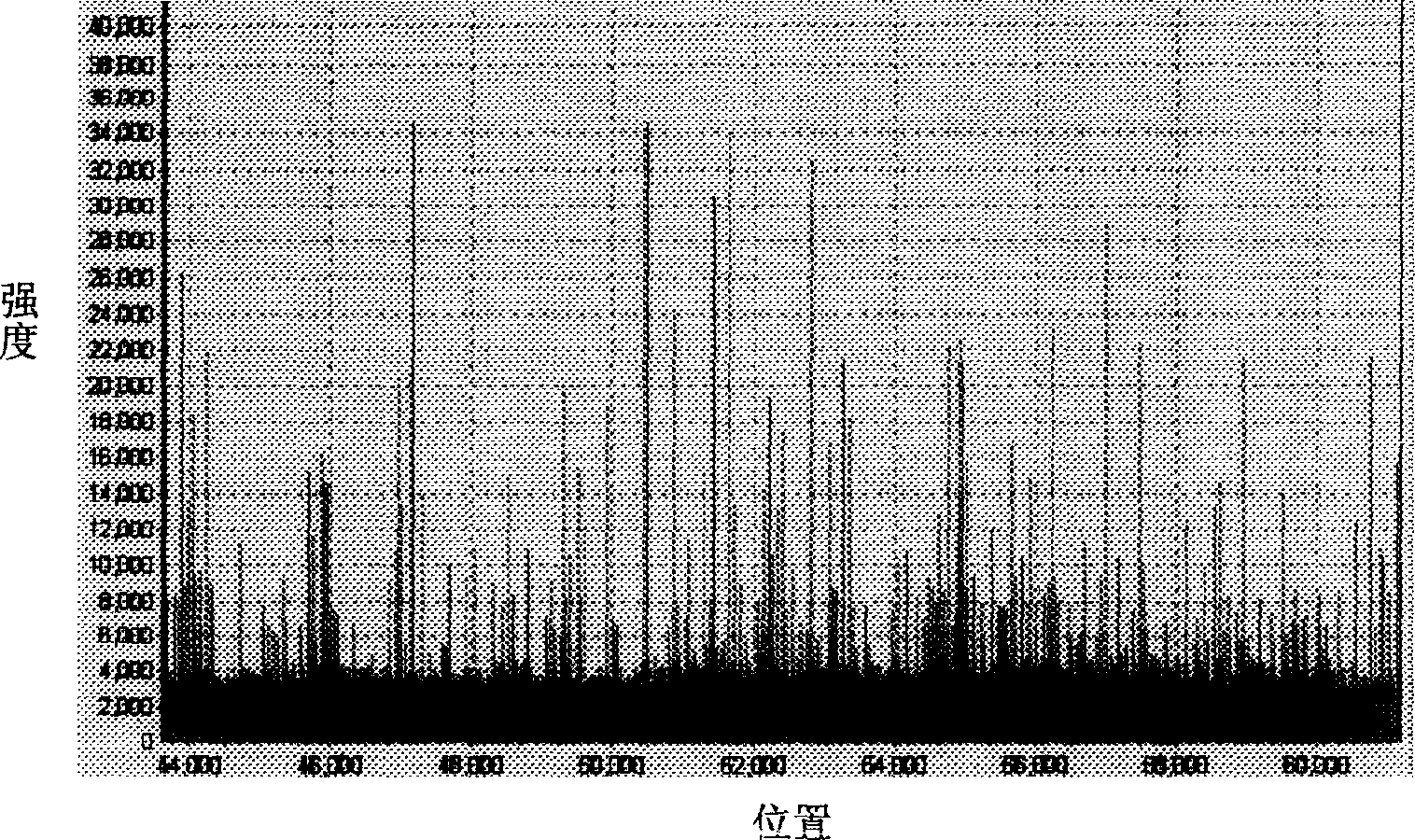

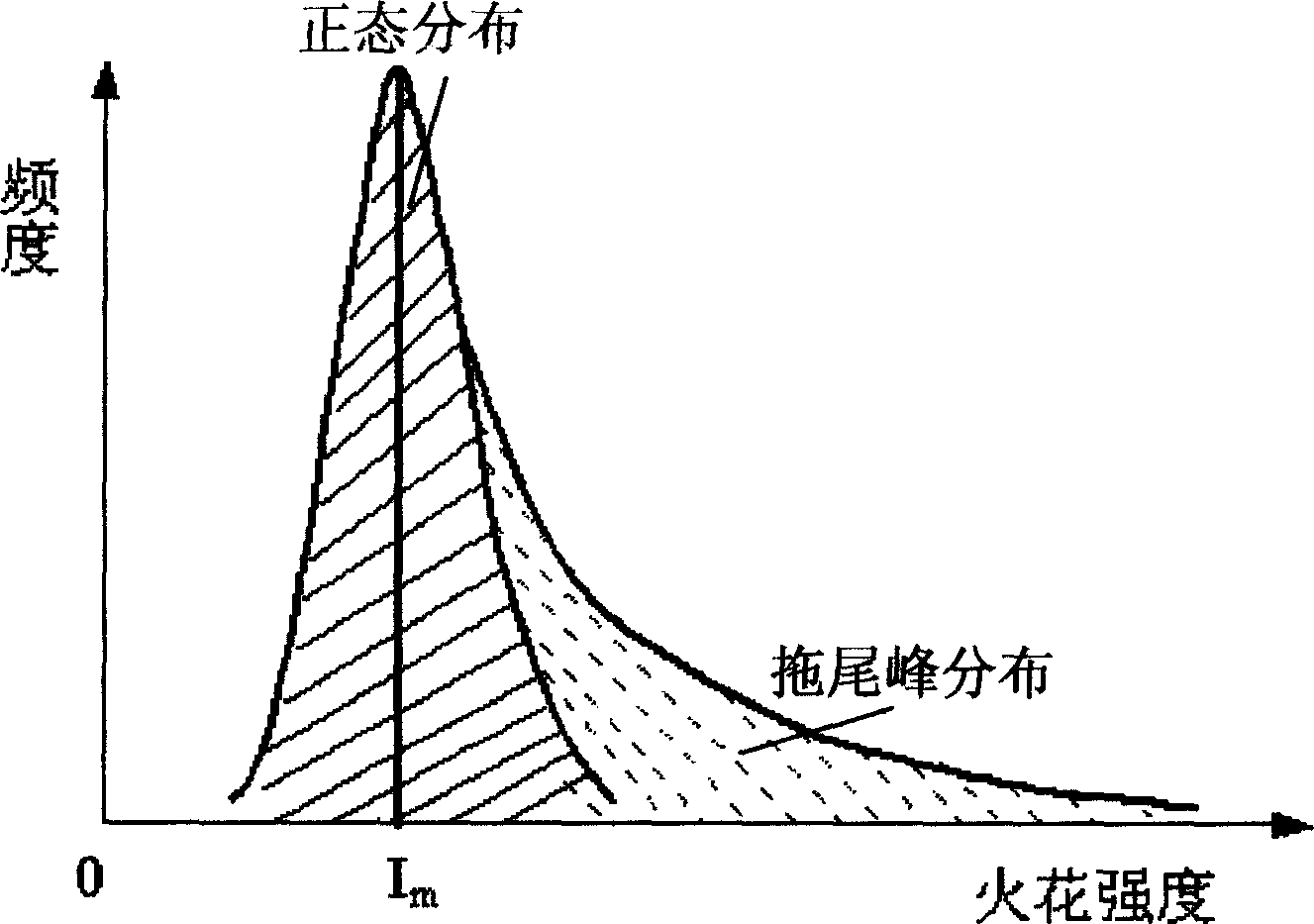

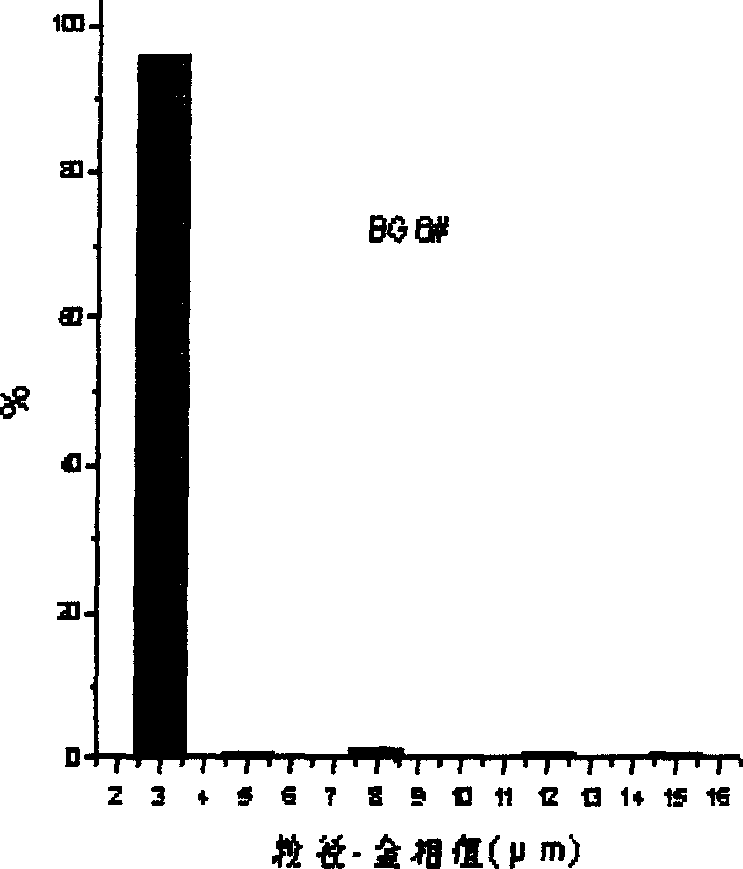

[0051] Using the in-situ analysis method for inclusions in metal materials according to the present invention, the inclusions in three steel samples were analyzed. The three samples were: aluminum deoxidized steel LY26#, low carbon steel TG1#, pure steel BK1 #, the chemical compositions of the three samples are shown in Table 1.

[0052] First, according to the excitation state and excitation performance of the three samples, select a sample as a control sample for routine analysis. First, carry out metallographic detection and analysis. This method completely follows the requirements of metallographic sample preparation, and wire-cuts the sample. A block sample of 20mm×20mm×20mm was obtained, and after rough grinding, fine grinding, polishing and other processes, it was observed under a metallographic microscope. The metallographic microscope used was Neophot-21. Because the field of view observed under the microscope is limited, in order to make the observed field of view ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| inductance | aaaaa | aaaaa |

| capacitance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com