Production of shrunk adhesive tape rough paper

A production method and technology of adhesive tape, applied in the field of papermaking, can solve the problems of easy penetration, easily broken base paper, unusable scrap, etc., and achieve the effects of good anti-seepage performance, convenient operation and reasonable production process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

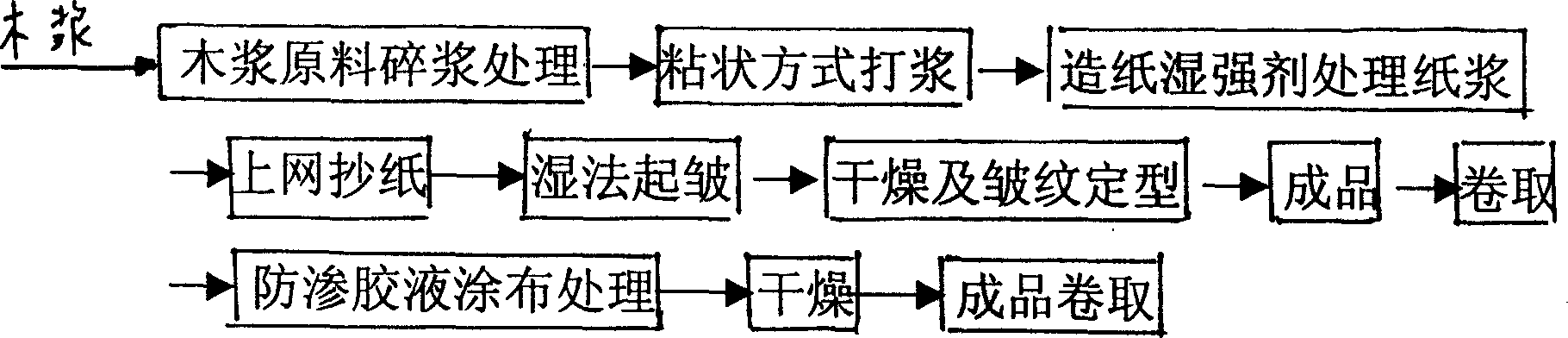

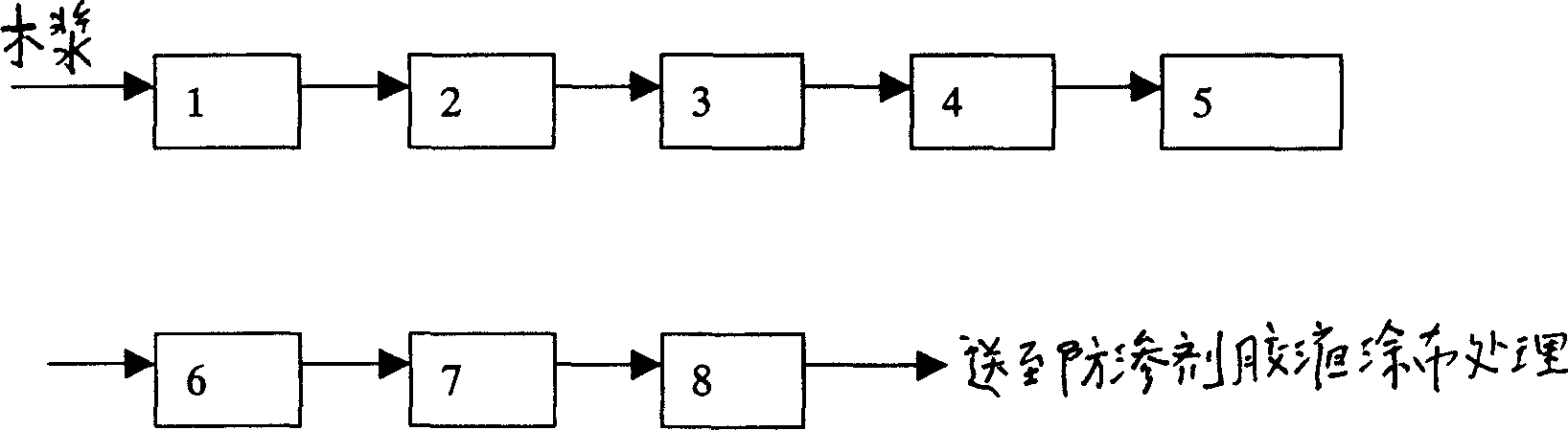

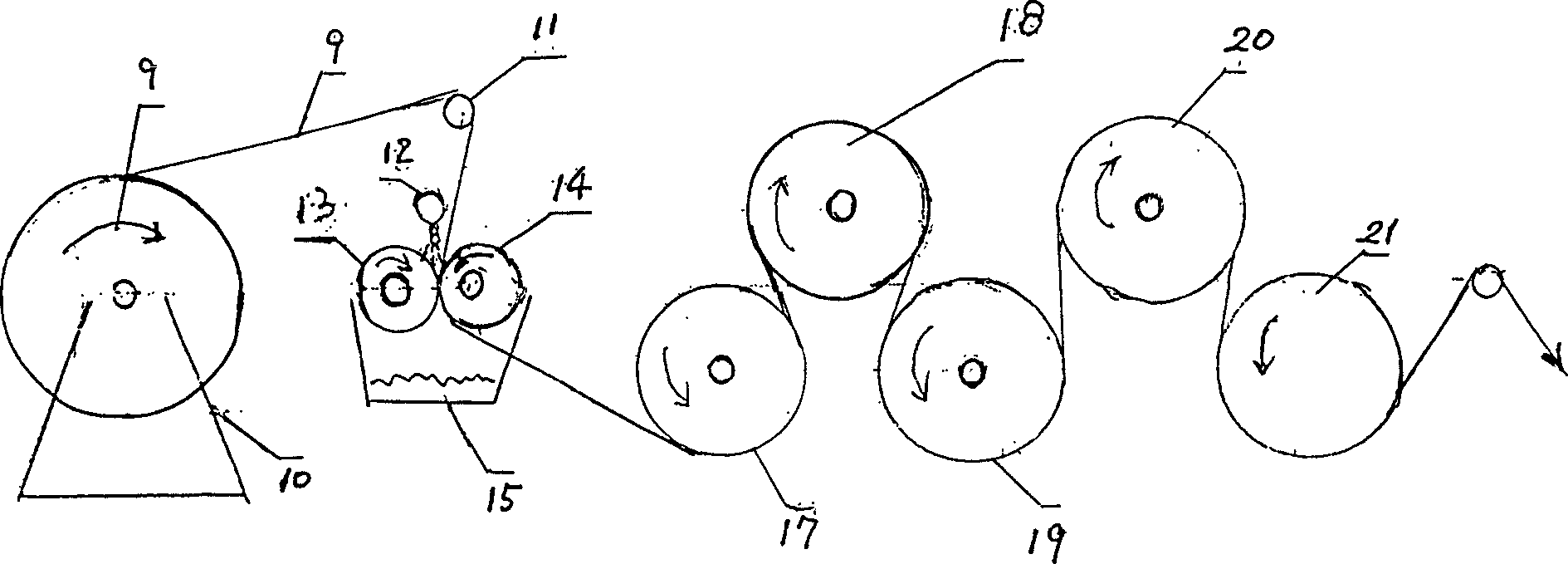

[0020] refer to figure 1 100% bleached softwood kraft pulp commercial pulp board is subjected to pulping treatment in the hydropulper 1, and the pulp after the pulping treatment is sent to the 1# pulp storage tank 2, and then sent to the trough beater 3 for Beating in a viscous way, the beating degree of the pulp is 45°SR-55°SR, and the pulp is sent to the 2# water solution that has been applied with the PAE-LT papermaking wet strength agent (cationic polyamide epichlorohydrin polymer) aqueous solution. Fully and uniformly mix with the PAE-LT papermaking wet strength agent aqueous solution in the stock tank 4 . According to the wood pulp kind selected by the present invention and the beating method thereof, a kind of PAE-LT papermaking wet strength agent (the product produced by Tongli Chemical Factory in Shijiazhuang, China) applied in the 2# pulp storage tank 4 can be quickly and efficiently It is absorbed and retained by the negatively charged pulp fibers, and undergoes a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com