Self-ionized and inductively-coupled plasma for sputtering and resputtering

A plasma and inductive coupling technology, used in sputtering plating, electro-solid devices, ion implantation plating, etc., can solve problems such as insufficient bottom coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

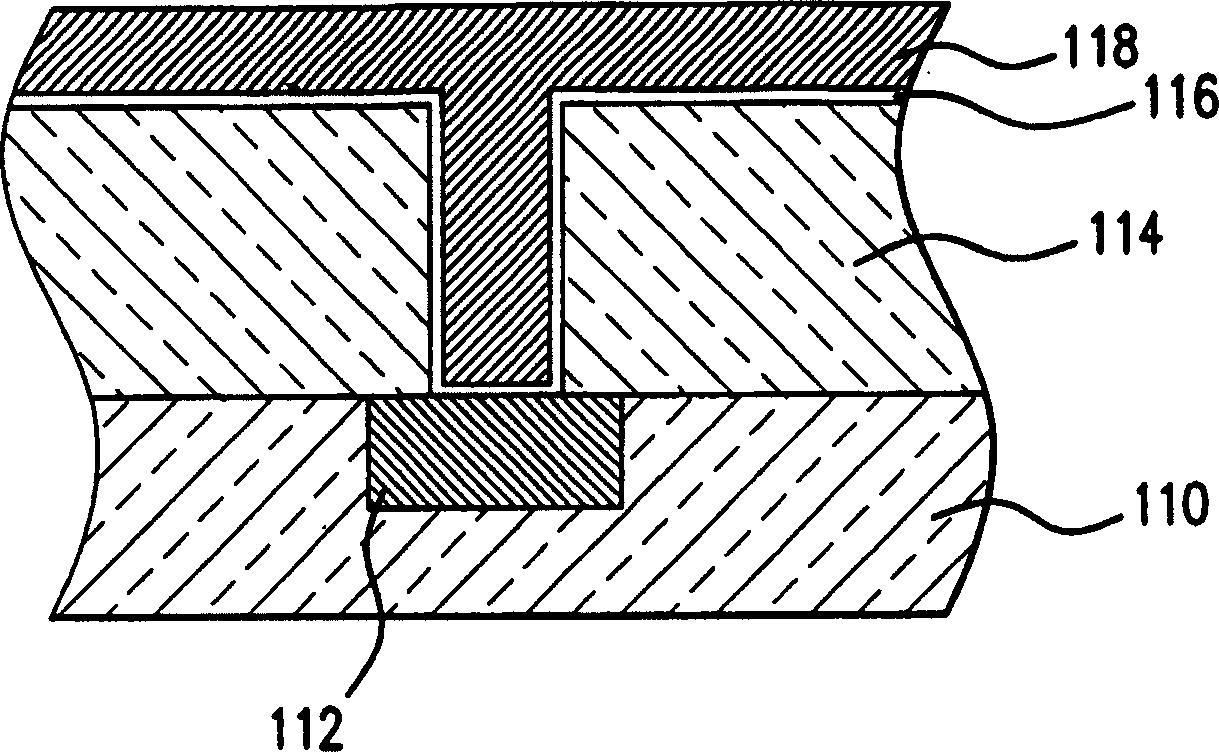

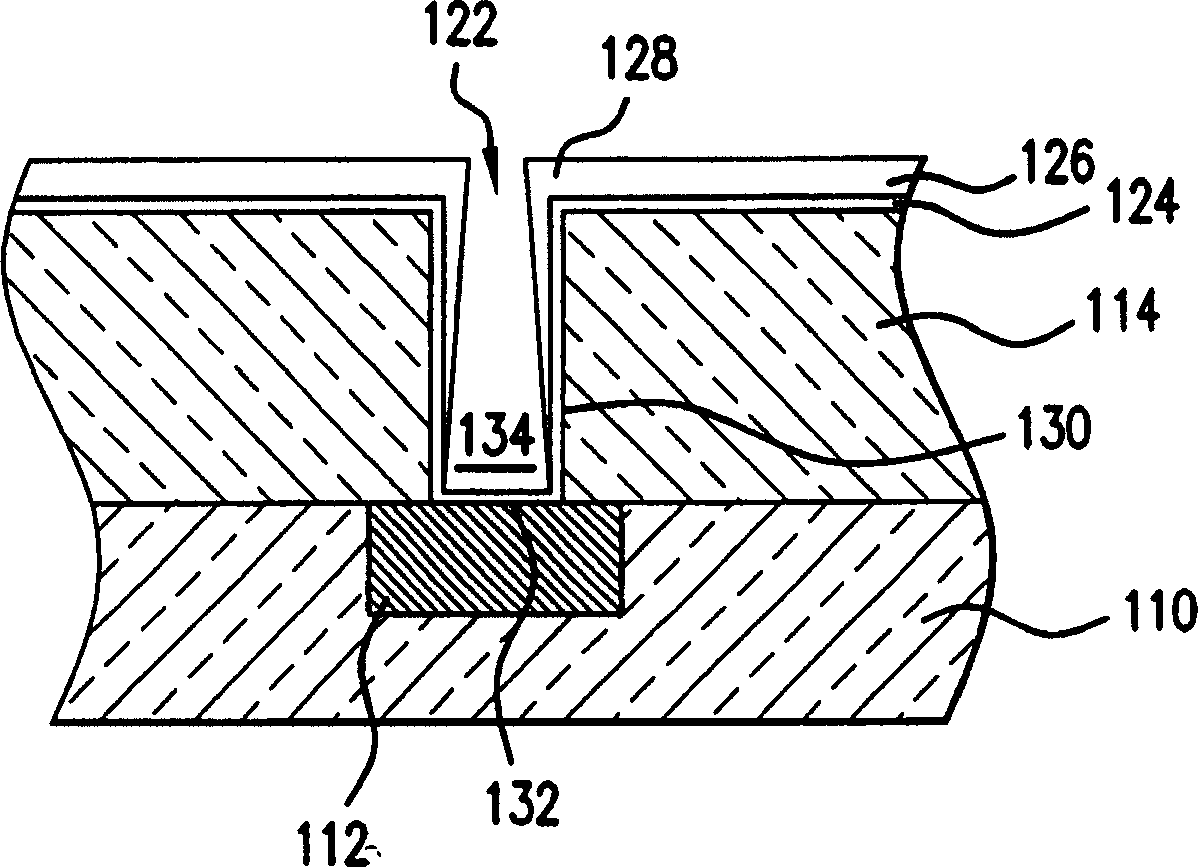

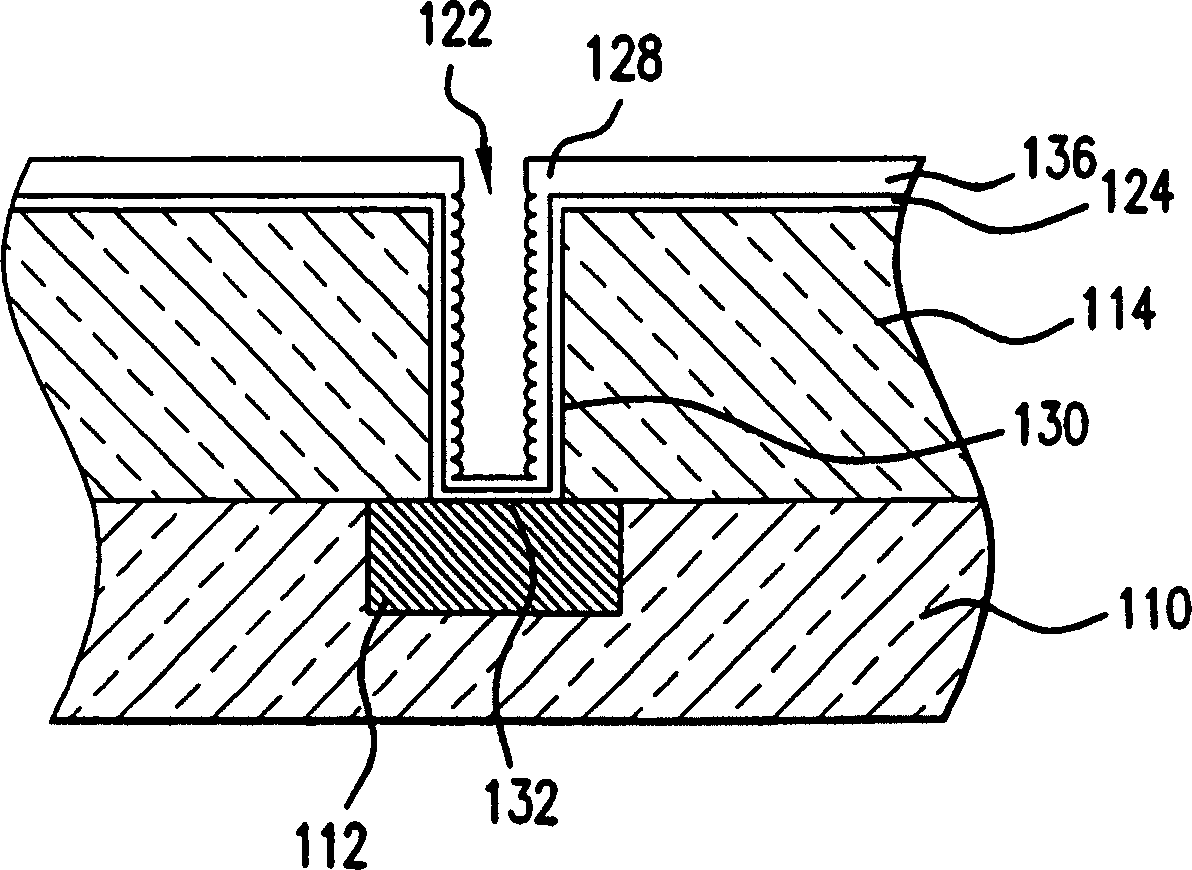

[0045] The distribution between sidewall and bottom cover in a DC magnetron sputtering reactor is suitable for making metal layers such as lining layers with desired profiles in holes or vias in dielectric layers. SIP films sputter-deposited into high-aspect-ratio vias can have good upper sidewall coverage and are less prone to protrusions. Bottom coverage can be thinned or eliminated by re-sputtering of the ICP at the bottom of the via, if desired. According to one version of the invention, the advantages of both types of sputtering can be obtained in a reactor which preferably combines a selected solution of SIP and ICP plasma generation techniques in the separation step. Examples of such reactors are Figure 4 150 summary instructions in . In addition, depositing the coil material onto the substrate by sputtering the ICP coil 151 located within the chamber keeps the upper portion of the liner layer sidewalls free from re-sputtering.

[0046] Reactor 150 may be used to dep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com