Method for preparing diaphragm of molten carbonate fuel cell

A technology of molten carbonate and fuel cells, which is applied in the direction of molten electrolyte fuel cells, fuel cell parts, battery pack parts, etc. The effect of severe pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Example 1: Ingredients according to the recipe:

[0057] α-LiAlO 2 : 45.0 g (coarse material (particle size > 1 μm) 95%, fine material (particle size < 1 μm) 5%)

[0058] Polyvinyl alcohol (PVA): 9.0 grams

[0059] Lactic acid: 2.3 grams

[0060] Glycerin and triacetin and glycol mixture (1 / 4 and 1 / 3 each of glycerin and triacetin): 5.0 g

[0061] Polyether compound: 0.8 g

[0062] Water: α-LiAlO 2 4.0 times of powder

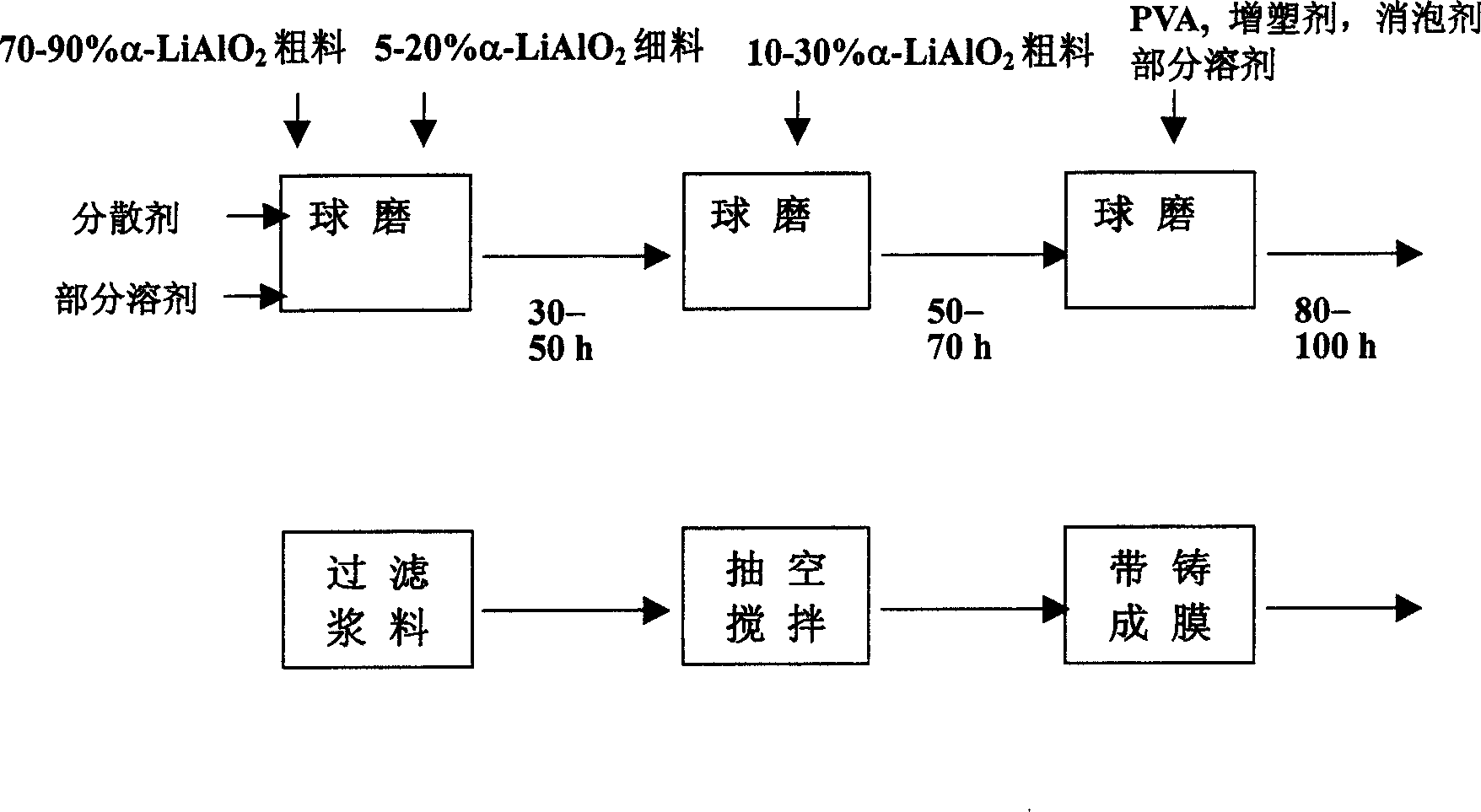

[0063] The order of feeding and the process flow of film making are according to figure 1 conduct. After hot pressing, the thickness of the battery separator is 0.69mm, and the bulk density is 1.84g / cm 3 .

[0064] The film test samples were prepared by simulating the conditions of slow battery heating and oxygen ventilation. It is measured that the maximum pore diameter is less than or equal to 1 μm, and the porosity is greater than or equal to 50%.

[0065] A battery is assembled with such a membrane, a sintered porous nickel plate as the ca...

Embodiment 2

[0067] According to the above formula ingredients, press figure 1 Sequence of addition and process flow to prepare the separator. After hot pressing, the thickness of the diaphragm is 0.74mm, and its bulk density is 1.81g / cm 3 . Then assemble and operate the single cell according to the above conditions. at 200 and 392.9mA / cm 2 Discharge, the battery output voltage is 0.882 and 0.638V respectively.

Embodiment 3

[0069] According to the above film-making formula ingredients, press figure 1 Sequence of addition and process flow to prepare the separator. It can be stored after being hot-pressed, or directly stored without hot-pressing after baking in an oven (when hot-pressing is required later, it can be baked in an oven at 60-70°C for 1 hour and then hot-pressed). The separator obtained above was stored at room temperature and air for more than one month, and then the single cell was assembled and operated according to the above conditions. at 200 and 300mA / cm 2 Discharge, the battery output voltage is 0.817 and 0.677V respectively. Compared with separators prepared with organic solvents and stored at room temperature and in air for the same period of time, the electrochemical performance of the separators prepared in water was much higher.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com