Fuel cell with variable porosity gas distribution layers

A fuel cell and gas distribution technology, applied in the field of battery systems, can solve problems such as difficult production and assembly, heavy bipolar plates and PEM components, and high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

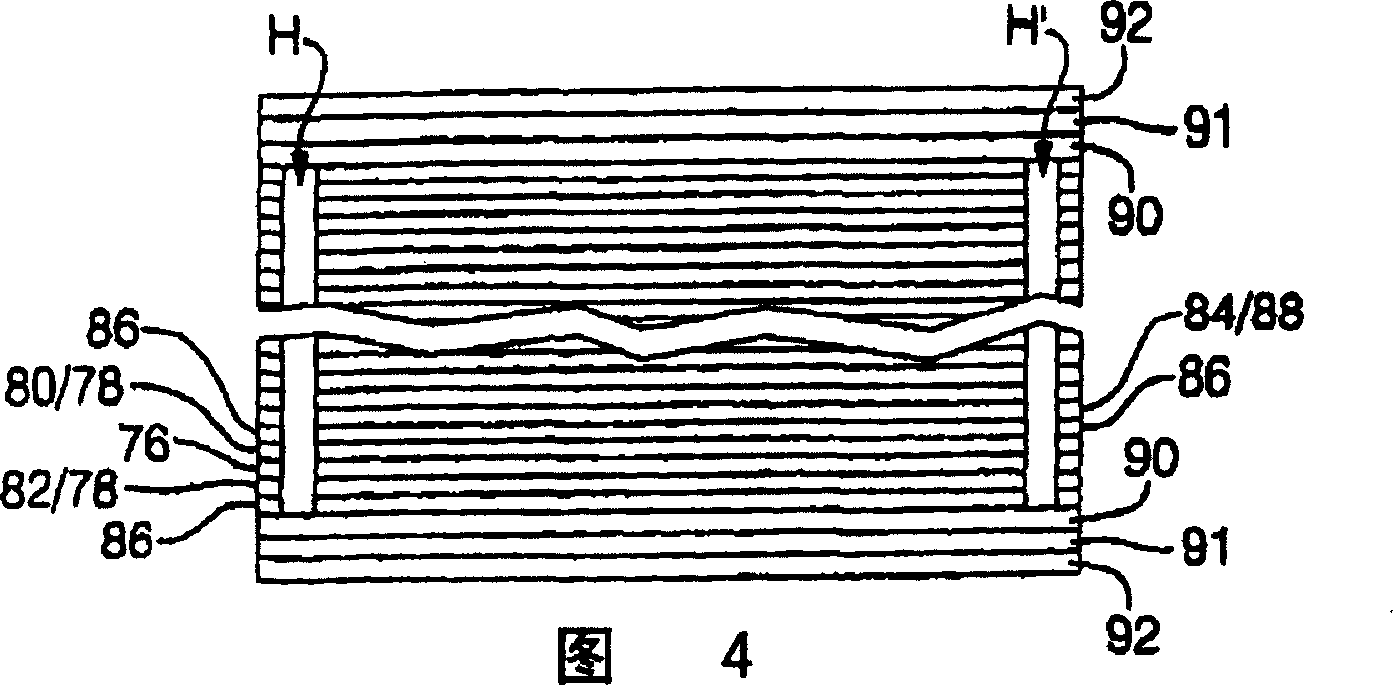

Embodiment Construction

[0034] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT

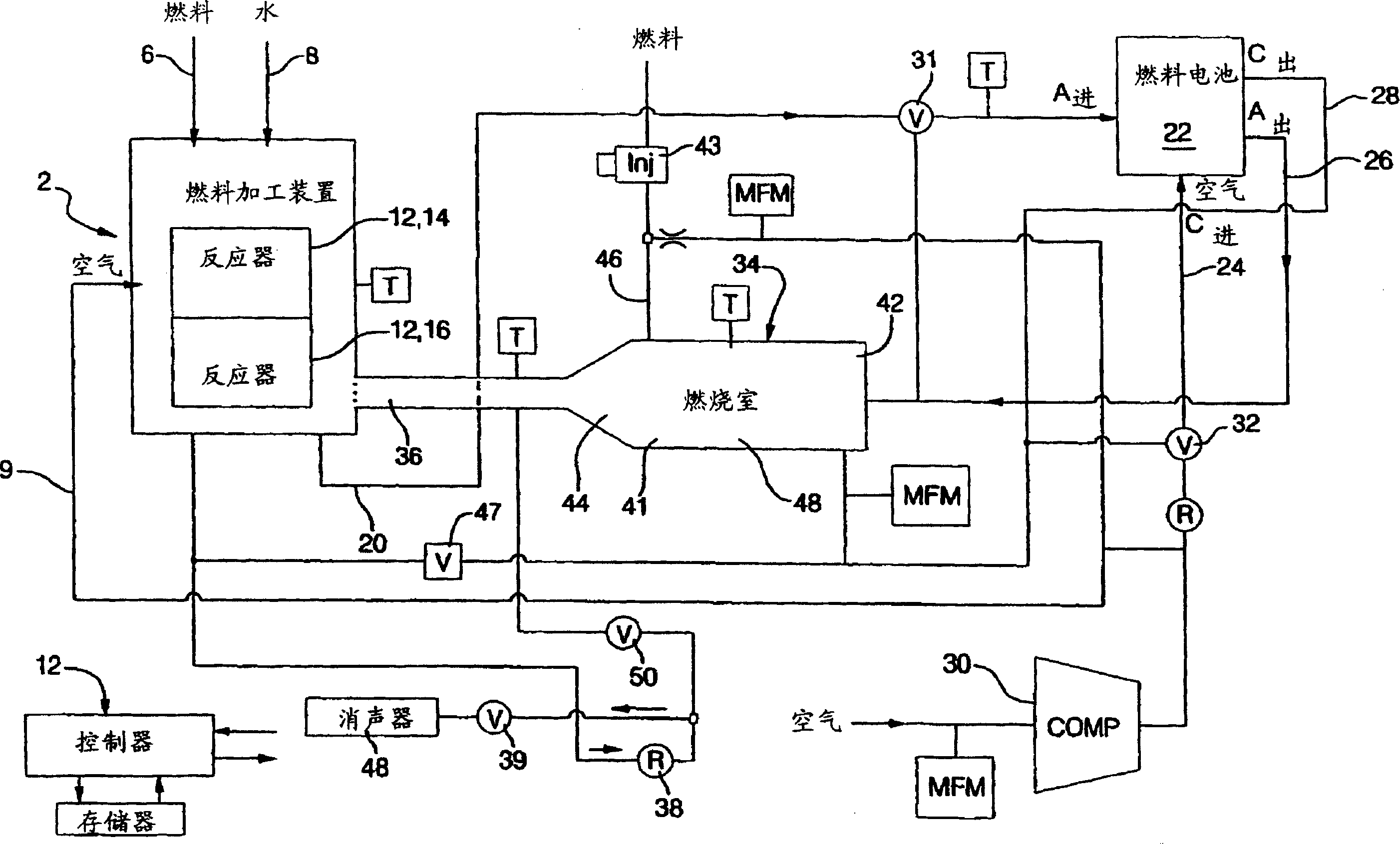

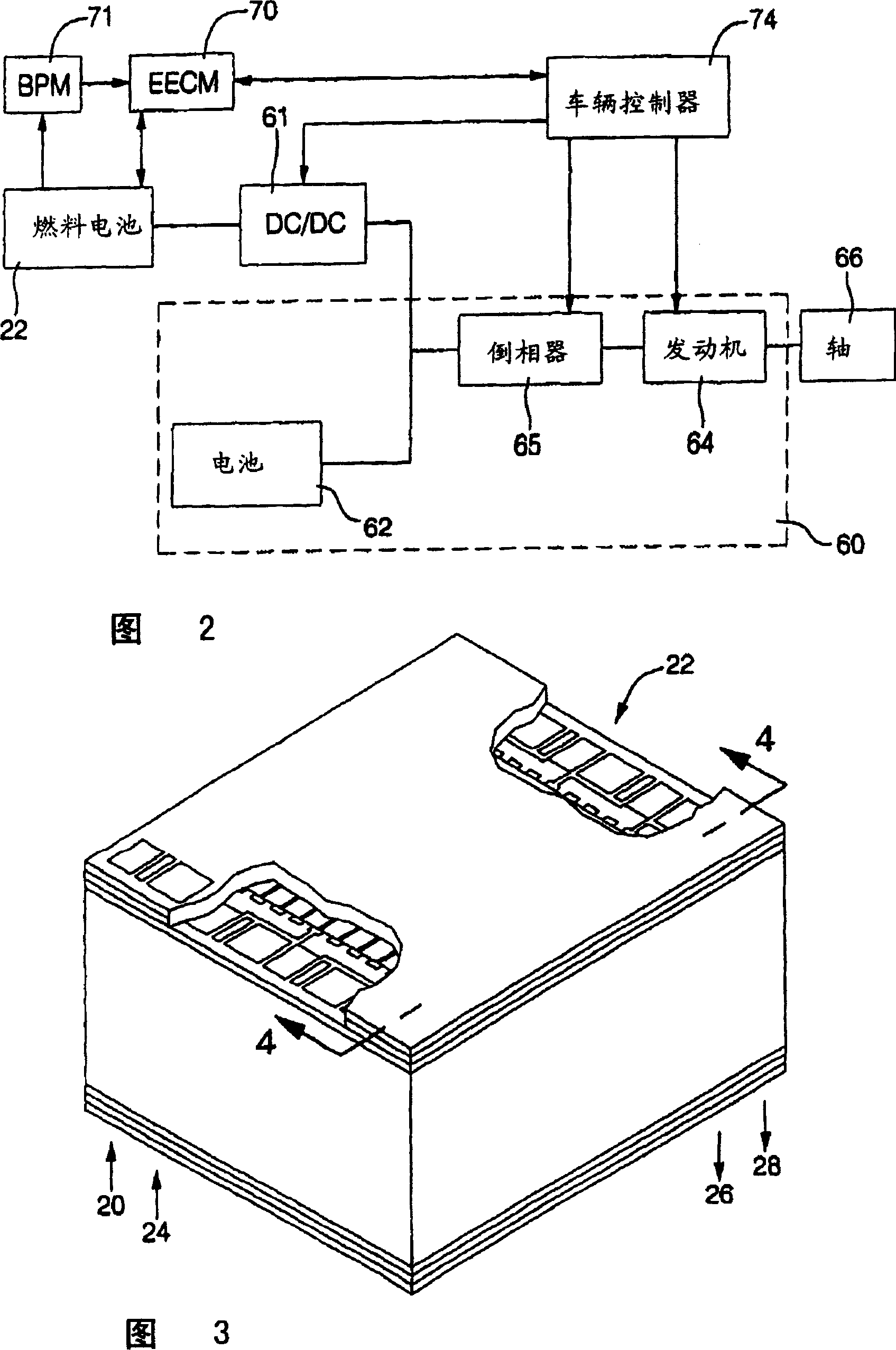

[0035] refer to figure 1 A fuel cell system is shown (by way of example only) to provide a further understanding of the invention. Before further describing the invention, it is therefore useful to understand the system in which the fuel cell of the invention operates.

[0036] figure 1 is an example of a fuel cell system. The system can be used in a vehicle (not shown) as a power source for driving the vehicle. In this system, hydrocarbons are processed in a fuel processing unit, such as by reforming and selective oxidation, to produce a reformate gas with a relatively high hydrogen content (volume or molar ratio). Accordingly, reference is made below to hydrogen-rich or relatively high hydrogen content.

[0037] The following will be in the rich H 2 The invention is described within the context of a fuel cell in which reformed gas is used as fuel, regardless of the method by which such reformed gas is produced. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com