Use of reaction type hindered amine, coating formula and method for in-situ photostabilization of coating layer

A light stabilizer and coating technology, applied in coatings, polyurea/polyurethane coatings, devices for coating liquids on surfaces, etc., can solve problems such as poor compatibility, loss of stabilizers, and poor thermal stability of HALS

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The in-situ light stabilized UV-curable coating system was prepared according to the following formula:

[0029] Component Amount (mass percentage)

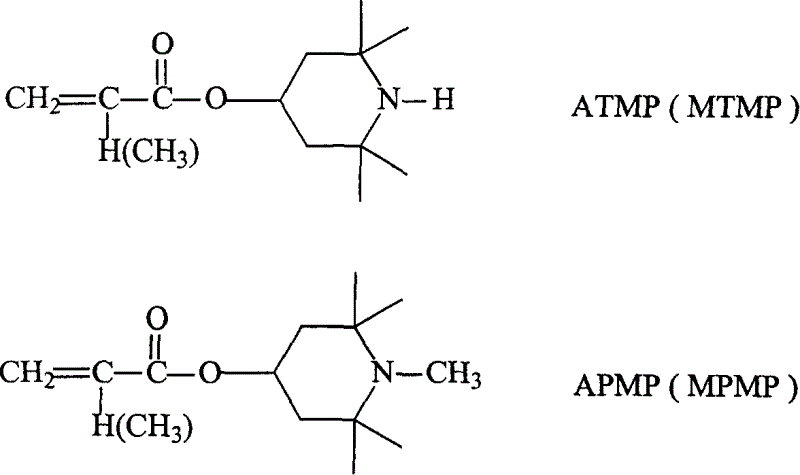

[0030] 4-Acryloyloxy-2,2,6,6-tetramethylpiperidinol (ATMP) 2.0

[0031] CN964 86.0

[0032] TPGDA 10.0

[0033] Irgacure651 1.5

[0034] Leveling agent 0.5

[0035] Each component is accurately weighed, and a UV-cured reactive prepolymerized mixture is prepared according to the above-mentioned polymer coating system formulation. The prepolymer must be mixed evenly, and placed in a dark place for overnight homogenization; the aged prepolymer is evenly coated on the PVC sheet with an applicator, the coating thickness is 20μm, and the A-528 thickness gauge is used to (produced by Guilin Measuring Tool Factory, with a sensitivity of 10 -2 mm) to measure the coating thickness of the sample; the PVC sheet coated with the aliphatic urethane acrylate coating is placed on a UV curing machine for photocuring, the light source is...

Embodiment 2

[0038] The in-situ light stabilized UV-curable coating system was prepared according to the following formula:

[0039] Component Amount (mass percentage)

[0040] 4-methacryloyloxy-2,2,6,6-tetramethylpiperidinol ester (MTMP) 2.0

[0041] Actilane 167 86.0

[0042] TPGDA 10.0

[0043] Irgacure651 1.5

[0044] Leveling agent 0.5

[0045] Each component is accurately weighed, and a UV-cured reactive prepolymerized mixture is prepared according to the above-mentioned polymer coating system formulation. The prepolymer must be mixed evenly, and placed in a dark place for overnight homogenization; the aged prepolymer is evenly coated on the PVC sheet with an applicator, the coating thickness is 10μm, and the A-528 thickness gauge is used to (produced by Guilin Measuring Tool Factory, with a sensitivity of 10 -2 mm) to measure the coating thickness of the sample; the PVC sheet coated with the aliphatic urethane acrylate coating is placed on a UV curing machine for photocuring, ...

Embodiment 3

[0048] The in-situ light stabilized UV-curable coating system was prepared according to the following formula:

[0049] Component Amount (mass percentage)

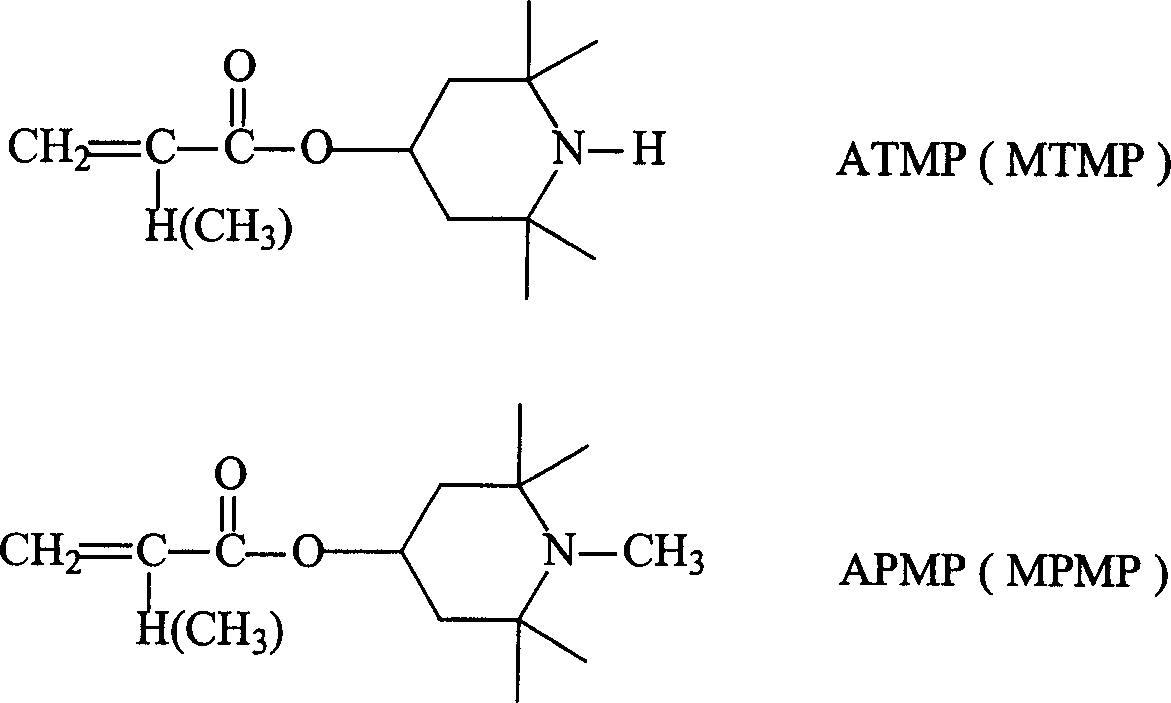

[0050] 4-acryloyloxy-1,2,2,6,6-tetramethylpiperidinol ester (APMP) 1.0

[0051] EBECRYL270 80.0

[0052] TMPTA 16.0

[0053] Darocurl173 2.5

[0054] Leveling agent 0.5

[0055] Each component is accurately weighed, and a UV-cured reactive prepolymerized mixture is prepared according to the above-mentioned polymer coating system formulation. The prepolymer must be mixed evenly, and placed in a dark place overnight for homogenization; the aged prepolymer is evenly coated on the PVC sheet with an applicator, the coating thickness is 15μm, and the A-528 thickness gauge is used to (produced by Guilin Measuring Tool Factory, with a sensitivity of 10 -2 mm) to measure the coating thickness of the sample; the PVC sheet coated with the aliphatic urethane acrylate coating is placed on a UV curing machine for photocuring, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com