Method for processing fent by comprehensive utilizing shrimp by enzyme method

A kind of scrap and enzymatic technology, applied in the field of processing scraps, can solve the problems of high recovery cost of protein and astaxanthin and difficult industrial production, and achieve the effect of promoting technological transformation and technical level, stable quality and improving recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

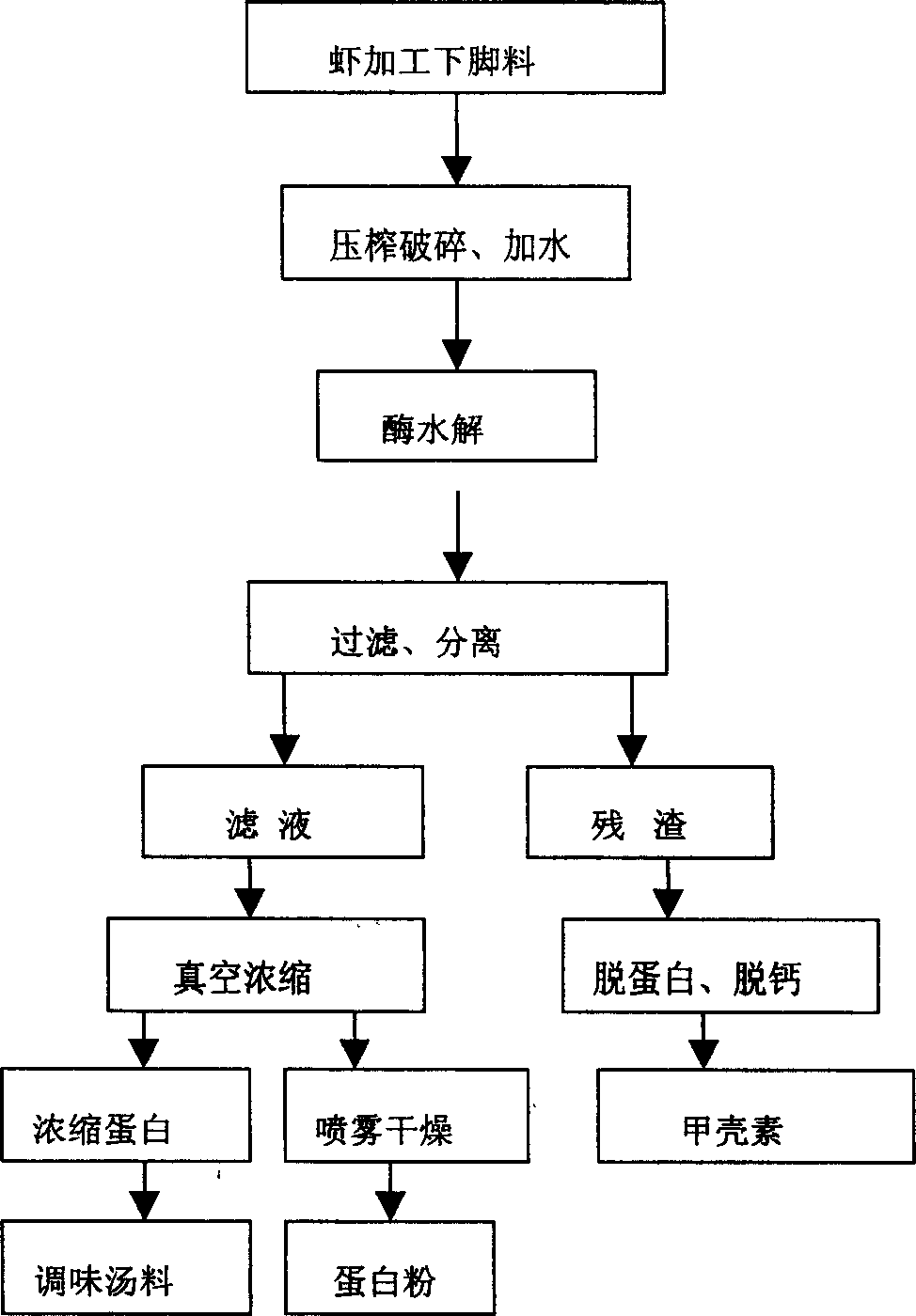

Image

Examples

Embodiment 1

[0027] The raw material is fresh shrimp processing waste, TVBN≤15mg / 100g. After crushing the leftovers, add water according to the mass ratio of leftovers / water 1:1, heat to 55°C and keep the temperature constant, adjust the pH to 8.0, add compound enzymes for enzymolysis, the enzymes are trypsin and Alcalase protease, two The ratio of the two enzymes is 1:1, the total dosage of the compound enzyme is 5000U / g protein according to the enzyme activity, and the reaction is carried out in the dark and stirred for 2 hours. After the reaction, use a 60-mesh filter to centrifugally filter, and the filtrate is vacuum-concentrated to 28% of soluble solids, and spray-dried to obtain protein powder rich in astaxanthin, with a protein content of 64.5% and an astaxanthin content of 1048 mg / kg. The remaining residue after filtration is used for the preparation of chitin.

Embodiment 2

[0029] The raw material is fresh shrimp processing waste, TVBN≤15mg / 100g. After crushing the leftovers, add water according to the mass ratio of leftovers / water 1:1.25, heat to 45°C and keep the temperature constant, adjust the pH to 8.0, add compound enzymes for enzymolysis, the enzymes are trypsin and AS.1398 protease , the ratio of the two enzymes is 4:6, the total amount of the compound enzyme is 3000U / g protein according to the enzyme activity, and the reaction is stirred for 3 hours in the dark. After the reaction, use a 60-mesh filter to centrifugally filter, and the filtrate is vacuum-concentrated to 20% of soluble solids, and spray-dried to obtain protein powder rich in astaxanthin, with a protein content of 58.1% and an astaxanthin content of 650 mg / kg. Other operations are the same as in Example 1.

Embodiment 3

[0031] The raw material is fresh shrimp processing waste, TVBN≤15mg / 100g. After crushing the leftovers, add water according to the leftovers / water mass ratio 1:1.5, heat to 65°C and keep the temperature constant, adjust the pH to 8.5, add compound enzymes for enzymolysis, the enzymes are trypsin and papain, two The ratio of the enzymes is 6:4, the total amount of the compound enzyme is 1000U / g protein based on the enzyme activity, and the reaction is stirred for 1 h in the dark. After the reaction, use a 60-mesh filter to centrifugally filter, and the filtrate is vacuum-concentrated to 35% of soluble solids, and spray-dried to obtain protein powder rich in astaxanthin, with a protein content of 55.8% and an astaxanthin content of 245mg / kg. Other operations are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com