Test table of automobile braking ABS based on brake inertia test

A technology of automobile braking and test bench, which is applied in the direction of measuring devices, machine/structural component testing, instruments, etc. It can solve the problems of high cost, different braking strength, and the inability to simulate the ABS performance test of cars, etc., so as to improve the utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

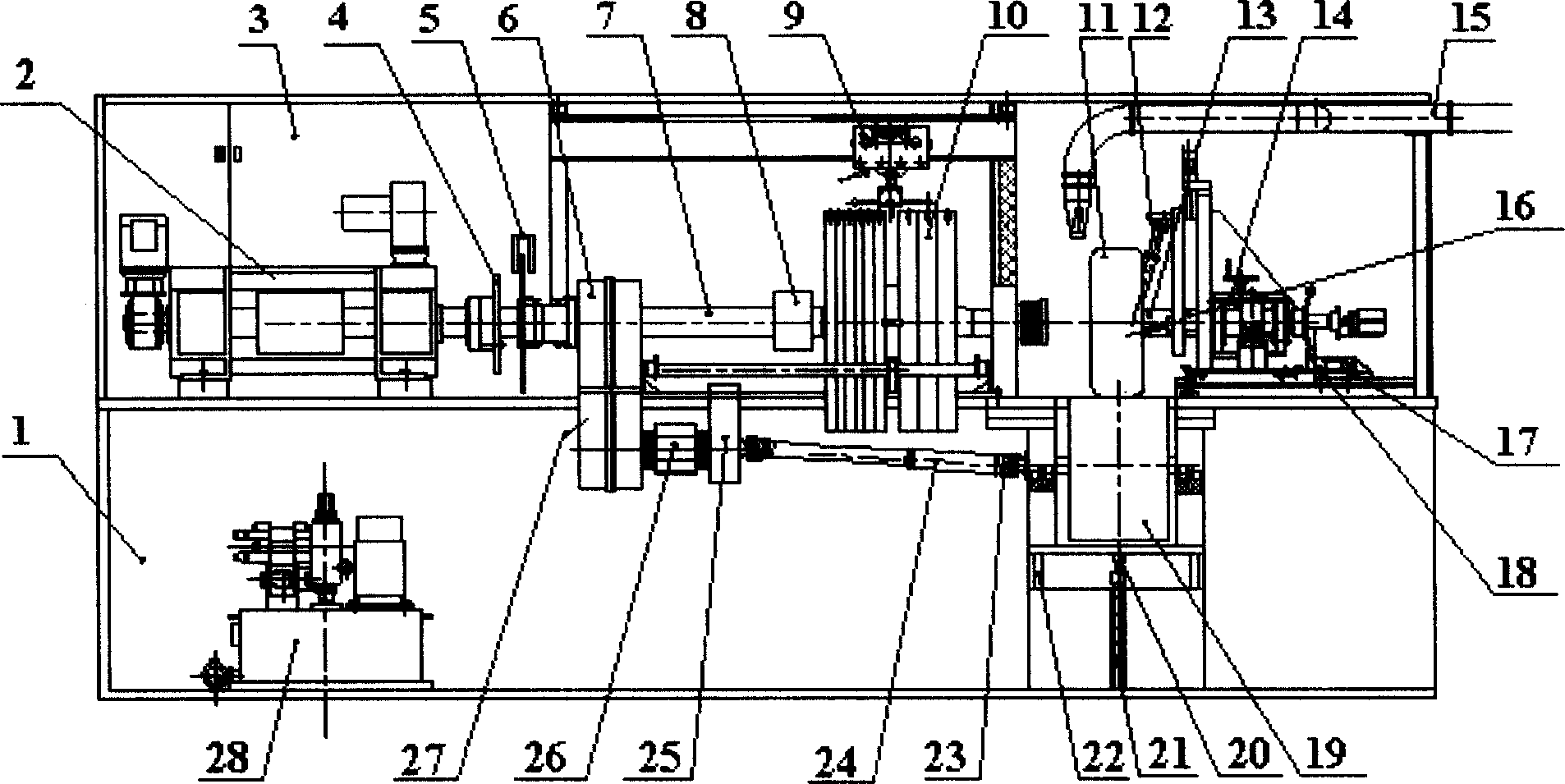

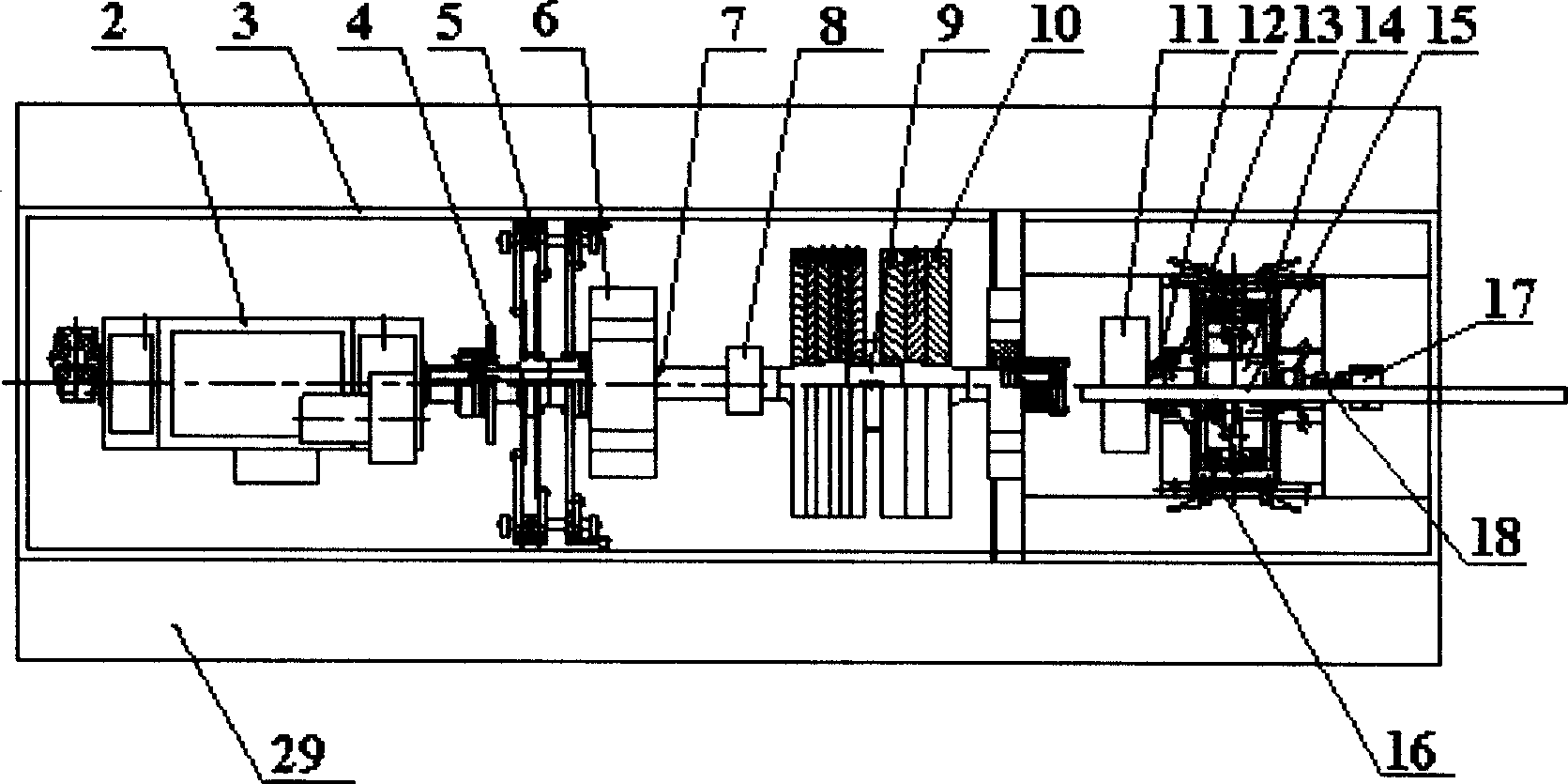

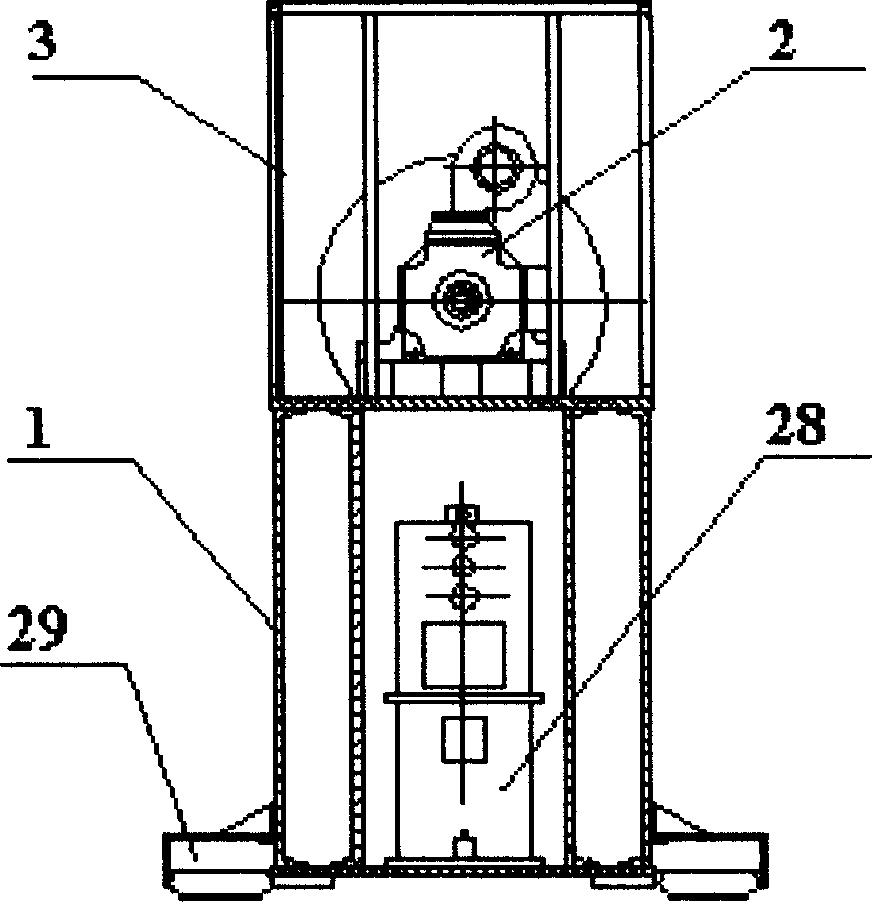

[0101] exist figure 1 , figure 2 and image 3 In the process, before the ABS performance test or the brake routine performance test, the wheel torque sensor (16) and the roller torque sensor (26) are calibrated by the static torque calibration mechanism (8), and the spindle speed is calibrated by an external standard tachometer. The sensor (4) and the wheel speed sensor (13) perform speed calibration, and the external standard pressure sensor performs pressure calibration on the lateral force sensor (18) and positive pressure sensor (20). After each sensor is calibrated and calibrated, it can be carried out Automotive ABS performance test or brake routine performance test.

[0102] exist figure 1 , figure 2 and image 3 Among them, when carrying out the ABS performance test, push the gear shift handle (27) of the gear box through the clutch / coupling oil cylinder of the gear box so that the sliding gear of the II shaft of the gear box (6) is in the combined position, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com